I realize I'm posting to an old thread, but I did some extensive searching before starting work on my upright keezer conversion, and found little concrete information from anyone who had successfully done this.

I used a Kenmore/Electrolux freezer model FFU17G9HW0. The service manual showed no lines in the sides of the fridge, but the sides got warm to the touch while it was running, so I knew there had to be something there.

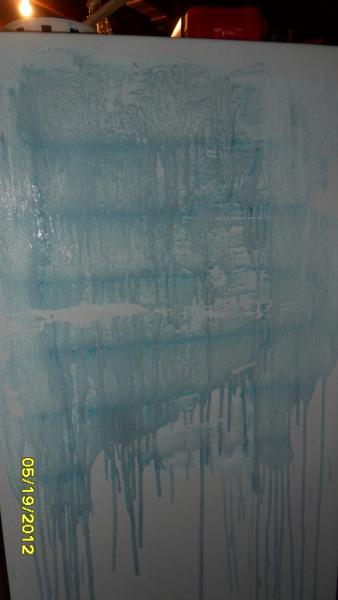

Based on other posts, I was able to put together the concept of using a vodka/corn starch slurry with food coloring to location the lines in the side of the fridge. I used a regular paintbrush to apply the mixture. One "gotcha" I found was that you really can't re-paint/re-coat without starting over. Goop it on heavy and in big strokes, covering lots of surface area. I found that even in a relatively thin mix, I was able to easily locate the lines that run through the side. They only took about 5 minutes to appear, and then stayed there. They were still visible the next day. The lines were spaced about 4" apart, allowing me to drill in between them without toasting my freezer.

Included are pictures of the corn starch showing the lines, a second version of that showing the tap holes, and the final product.

Granted, this method will NOT find the evaporator (cold) lines. I used a dremel tool to cut the inside of the freezer first, just to be safe, then poked around looking for any lines I might be missing, using a screwdriver to carefully remove the foam insulation and then feeling around with my finger until I got to the outside wall.

Hopefully this may help others in the same situation in the future who are considering putting taps on the side of an upright freezer.

As I think about it, it seems like a dumb question 'cause there would have to be hard lines running from the body of the freezer to the door for the refrigerant. That would make it difficult to open and close

As I think about it, it seems like a dumb question 'cause there would have to be hard lines running from the body of the freezer to the door for the refrigerant. That would make it difficult to open and close I guess I was just freaking out a little. New kegerator here I come!

I guess I was just freaking out a little. New kegerator here I come!