HenryVance3

Well-Known Member

I have been searching for good PWM plans and found a some that are worth sharing. For those who are wanting modulated overkill click this link

http://www.overclockers.com/pwm-fan-controller

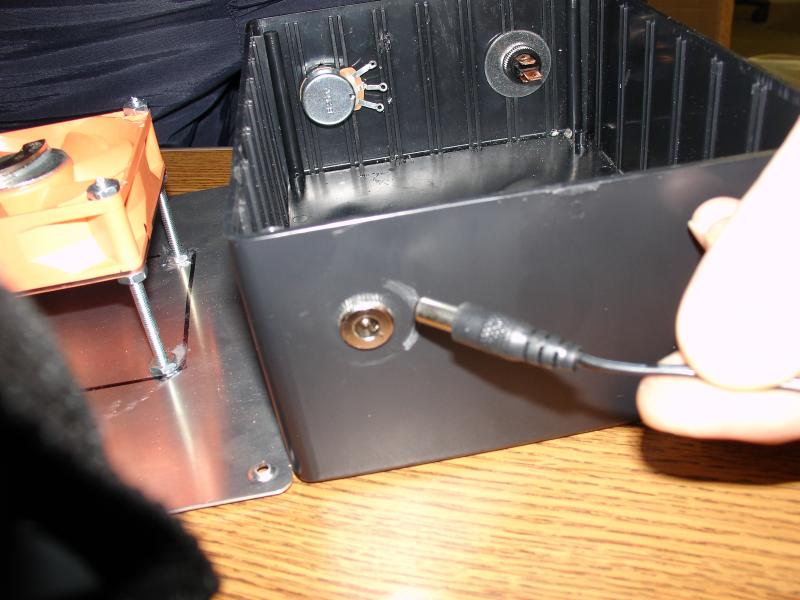

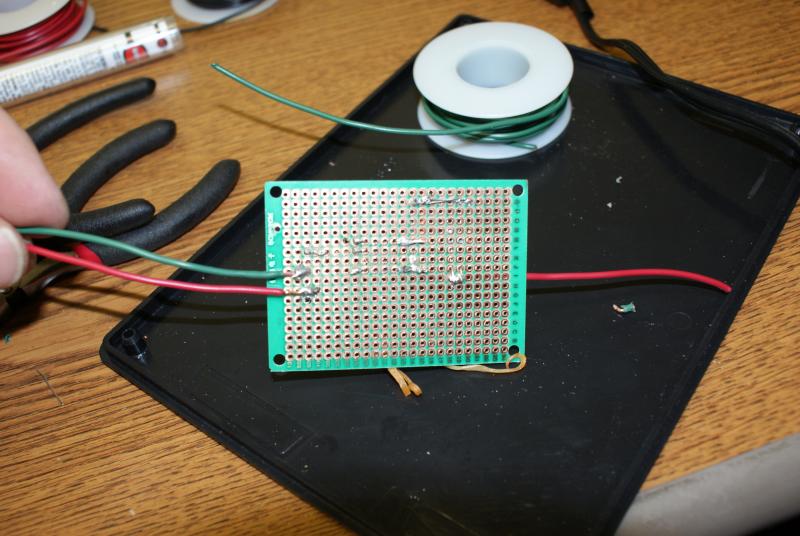

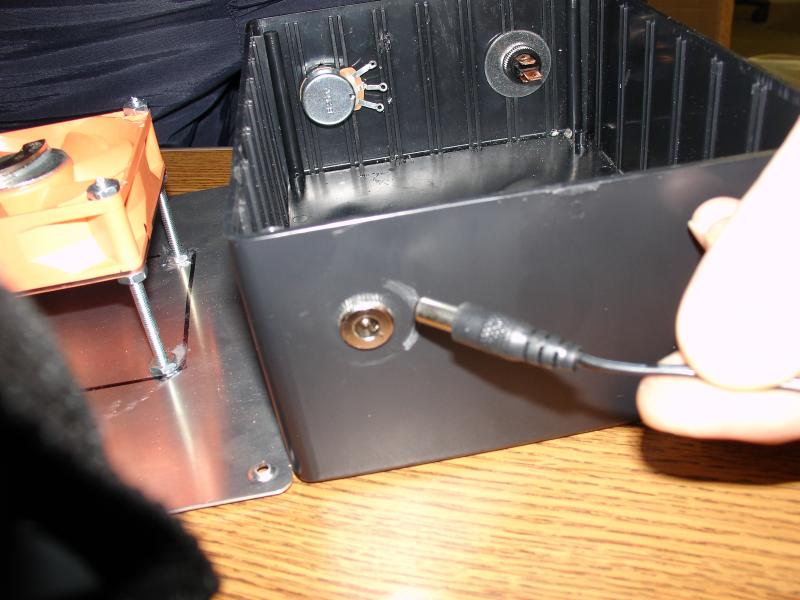

I went the route of so many before me with the project box from radio shack and some fan I scrounged along with Hard drive magnets. I also found a lot of DC plugs from 6 volts to 12volts with a type M plug. This is important because you can get a female adapter at Radio Shack pictured in the back right corner of my box for a clean connection.

I will post more as my project continues.....

What is the best way you all have found to balance the magnet on the fan?

______________________________________________________

"Are you gonna be working on your Brew Stuff? Yes Honey, I will be working on my Brew Stuff."

http://www.overclockers.com/pwm-fan-controller

I went the route of so many before me with the project box from radio shack and some fan I scrounged along with Hard drive magnets. I also found a lot of DC plugs from 6 volts to 12volts with a type M plug. This is important because you can get a female adapter at Radio Shack pictured in the back right corner of my box for a clean connection.

I will post more as my project continues.....

What is the best way you all have found to balance the magnet on the fan?

______________________________________________________

"Are you gonna be working on your Brew Stuff? Yes Honey, I will be working on my Brew Stuff."