movet22

Well-Known Member

So before I get into the brief back story, here is the brief-er beck-er story: I have been brewing for almost 5 years, started with extract batches in my college apartment and have just finished my 7th AG batch a few minutes ago. I have, within the past 5 months, gotten engaged, bought a house and moved out of my parents house and in with my fiance.

This is all relevant because, I have moved my MacGuyver-esque propane fueled AG set up to our new house and brewed for the first time with it in the new digs tonight. My fiance was NOT happy that I was using such an intense flame (banjo) on the new front porch (In my defense, it was supposed to rain, I needed the cover). She was so appalled that she demanded that I drastically upgrade before I brew again.

This all brings me to the electric forum. I have just been given full reign over the entire basement (which has a utility sink already) and have been told to go completely electric. Including pumps, a control panel and a fermentation chamber. (The frem chamber is just another thing she wants me to make so that my carboys do not sit in the air conditioned living room.)

Let me start by laying out my current set up, of which I plan to mostly keep: 10 gal aluminum HLT, 10 gal orange rubbermaid cooler MLT and an 8 gal stainless boil kettle. I just got a brand new circuit breaker in the basement so I plan on getting a spa panel installed within the next few days, maybe a week.

My first question is, what should I expect to spend on a generally simple 2 element build? (I am hoping to keep in under $1k.)

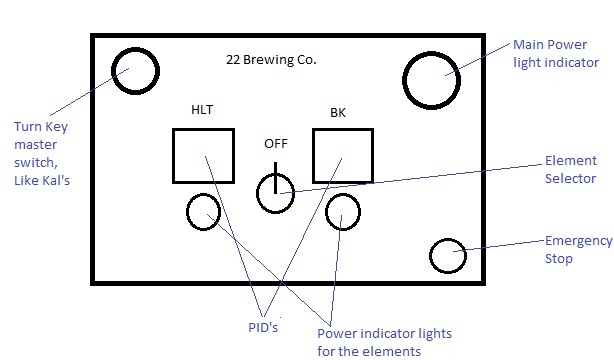

I am also going to post a mock up of what I have in mind for a control panel in the morning, hopefully I can get some critique and suggestions.

Feel free to follow me as I build my budget friendly dream set up, and suggest anything you can think of along the way.

Thanks in advance for all the input!

This is all relevant because, I have moved my MacGuyver-esque propane fueled AG set up to our new house and brewed for the first time with it in the new digs tonight. My fiance was NOT happy that I was using such an intense flame (banjo) on the new front porch (In my defense, it was supposed to rain, I needed the cover). She was so appalled that she demanded that I drastically upgrade before I brew again.

This all brings me to the electric forum. I have just been given full reign over the entire basement (which has a utility sink already) and have been told to go completely electric. Including pumps, a control panel and a fermentation chamber. (The frem chamber is just another thing she wants me to make so that my carboys do not sit in the air conditioned living room.)

Let me start by laying out my current set up, of which I plan to mostly keep: 10 gal aluminum HLT, 10 gal orange rubbermaid cooler MLT and an 8 gal stainless boil kettle. I just got a brand new circuit breaker in the basement so I plan on getting a spa panel installed within the next few days, maybe a week.

My first question is, what should I expect to spend on a generally simple 2 element build? (I am hoping to keep in under $1k.)

I am also going to post a mock up of what I have in mind for a control panel in the morning, hopefully I can get some critique and suggestions.

Feel free to follow me as I build my budget friendly dream set up, and suggest anything you can think of along the way.

Thanks in advance for all the input!