mtbiker278

Well-Known Member

Hey All!

I finally started construction on my Keezer build. I scored a Kenmore 14.8 cuft chest freezer for $150 on craigslist. I was inspired by Jester's awesome build and the many replica's that followed. Here's the thread on Jester's build that I'm using for reference.

I'm still waiting for my temp controller to put my kegs in but by a rough guess it should hold at least 7 kegs on the floor.

\

\

So far I've made the dolly out of a 19/32" sheet of plywood and some 2x6's. The plywood is 1" wider than the freezer to allow for some room. The 2x6's frame the plywood. The casters are screwed in at the corners.

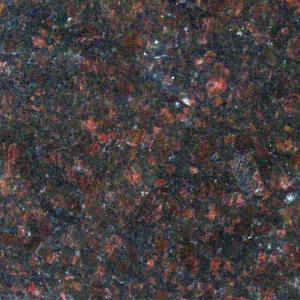

Lowes had some pretty nice red oak boards that I'm probably going to use to trim out the rest of the keezer. I'm hoping It'll look nice stained a redish tone with maybe some dark marble or granite inlays.

More to come!

I finally started construction on my Keezer build. I scored a Kenmore 14.8 cuft chest freezer for $150 on craigslist. I was inspired by Jester's awesome build and the many replica's that followed. Here's the thread on Jester's build that I'm using for reference.

I'm still waiting for my temp controller to put my kegs in but by a rough guess it should hold at least 7 kegs on the floor.

So far I've made the dolly out of a 19/32" sheet of plywood and some 2x6's. The plywood is 1" wider than the freezer to allow for some room. The 2x6's frame the plywood. The casters are screwed in at the corners.

Lowes had some pretty nice red oak boards that I'm probably going to use to trim out the rest of the keezer. I'm hoping It'll look nice stained a redish tone with maybe some dark marble or granite inlays.

More to come!