You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sour smell in primary? Infected?

- Thread starter Amity

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

bearkluttz

Well-Known Member

Let it be. back up and give those yeasties room to maneuver.

Loup

Well-Known Member

my first batch had a bit of a sour smell (and taste) after a few days, it's now been 4 weeks since I first brewed it and it tastes fine, no longer sour. It might just smell that way because it's still young. My second batch still hasn't touched air since I first brewed it, so I don't know what it smells like.

jds

Well-Known Member

Fermenting is not a pretty process. Put the lid back on and ignore it for a week, and I bet your yeast will take care of everything for you.

MNBugeater

Well-Known Member

All normal. When I get on a roll and have 6-8 carboys fermenting all in one room, my SWMBO always complains about the 'smell' in that room.

She irons in that room and she walks out saying "Ugh..It stinks in there..."

I laugh and say..."Hell, I'm sleeping in there."

She irons in that room and she walks out saying "Ugh..It stinks in there..."

I laugh and say..."Hell, I'm sleeping in there."

RDWHAHB. Just wait and taste it in a month, then start to worry a little bit if it tastes off. If it does, give it a month more. Its all about patience. As a popular food TV icon always says, your patience will be rewarded (Alton Brown).

JBrady

Well-Known Member

I Heart Yeast Farts

TheFlatline

Well-Known Member

I put my first brew in the primary on Saturday, and it's smelling sour at the moment. OG is 1020, it's now at 1010. It's a nut brown ale. Any ideas?

Is it just me or does 1.020 seem low for a SG?

I was wondering about that 1.020, too. When my son started his first batch he called me because his OG was too low (an extract kit). I had him go back and stir it up and, lo and behold, it was up to the expected range. Probably had all the wort on the bottom of the fermenter.

EvilTOJ

Well-Known Member

Most of the time when the OG is low with extract beer, it's because the topup water wasn't thoroughly mixed with the boil.

Yagermyster

Active Member

- Joined

- Nov 23, 2017

- Messages

- 26

- Reaction score

- 0

I worried my beer isn't doing right I started on Sunday and the airlock was bubbling every 5-6 sec and then Tuesday it wasn't bubbling at all so I moved it and the glass fermenter felt like ice I check with the temperature it said 40°f so I moved it to get warm then it started bubbling every 8-10 secs now it's not doing anything and smells sour and I seen to add a little more yest to it so I did but still nothing. So is it gone or is there still hope? Oh and the airlock keeps sucking water in is it post to do that?

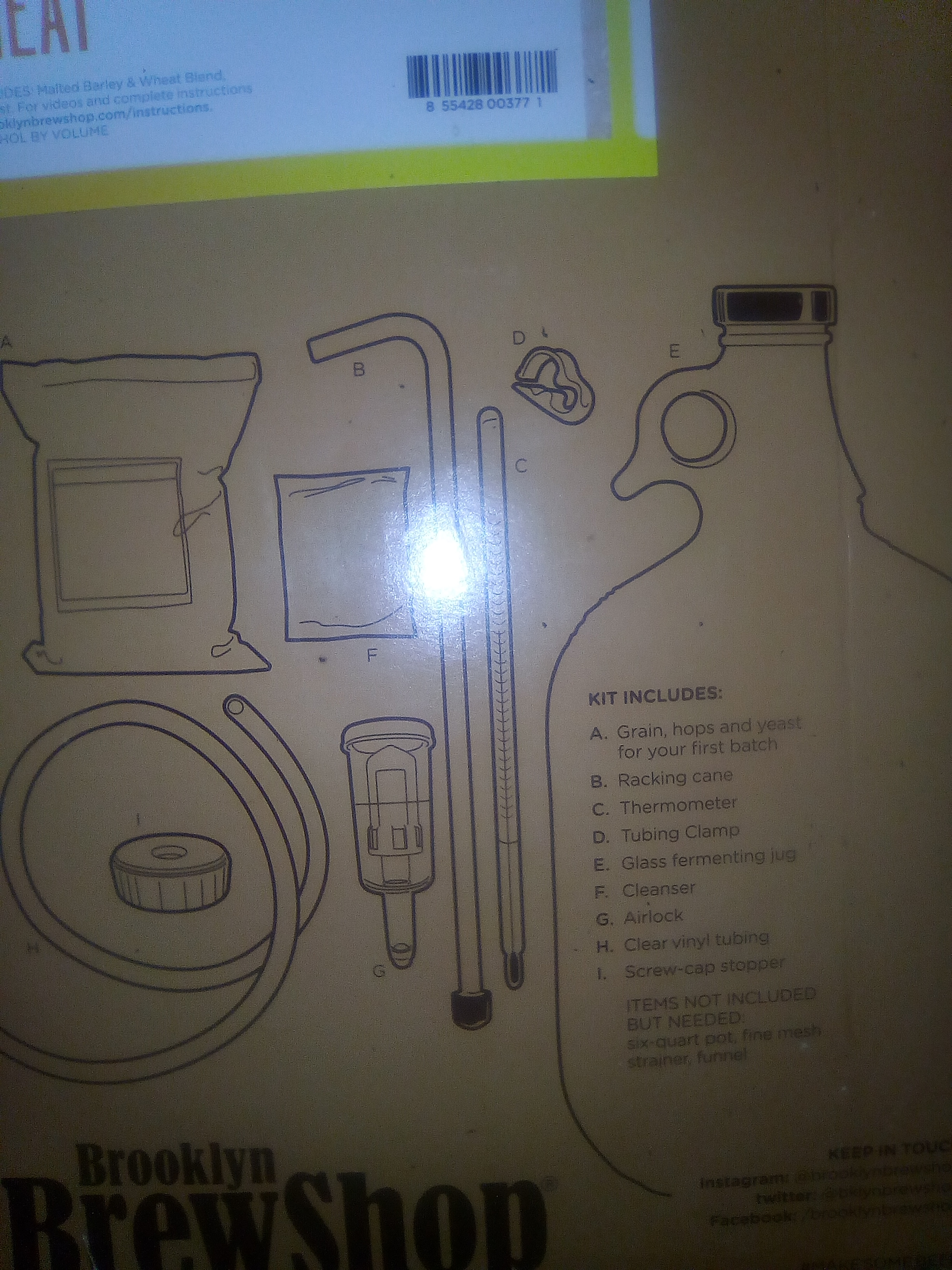

My beer is a Brooklyn brewshop afternoon wheat starter kit

My beer is a Brooklyn brewshop afternoon wheat starter kit

At 40*F thats basically a cold crash. Your air lock sucking water is due to the warmer temp inside the fermenter compared to the ambient air outside the fermenter. It creates a vacuum. Sounds like you need to move the fermenter back to a warmer place to let it finish. 40 is too cold

Yagermyster

Active Member

- Joined

- Nov 23, 2017

- Messages

- 26

- Reaction score

- 0

Ok I've been keeping it warm and it didn't have any action in airlock so Friday I add a tablespoon of yeast and some table sugar and got action till Saturday I sneaked a taste and it was bitter and kinda tasted like whiskey I took about a double shot glass and tryed to bottle it to see if it would carbante but it didn't do any fizz or anything so I guess it to soon?At 40*F thats basically a cold crash. Your air lock sucking water is due to the warmer temp inside the fermenter compared to the ambient air outside the fermenter. It creates a vacuum. Sounds like you need to move the fermenter back to a warmer place to let it finish. 40 is too cold

Ok I've been keeping it warm and it didn't have any action in airlock so Friday I add a tablespoon of yeast and some table sugar and got action till Saturday I sneaked a taste and it was bitter and kinda tasted like whiskey I took about a double shot glass and tryed to bottle it to see if it would carbante but it didn't do any fizz or anything so I guess it to soon?

Let's take a step back for a minute. Before you can bottle anything you need to know if you're done fermenting.

1. Did you check your OG before pitching yeast? If so, what was it?

2. Have you checked your FG to make sure you're done fermenting? What was this number?

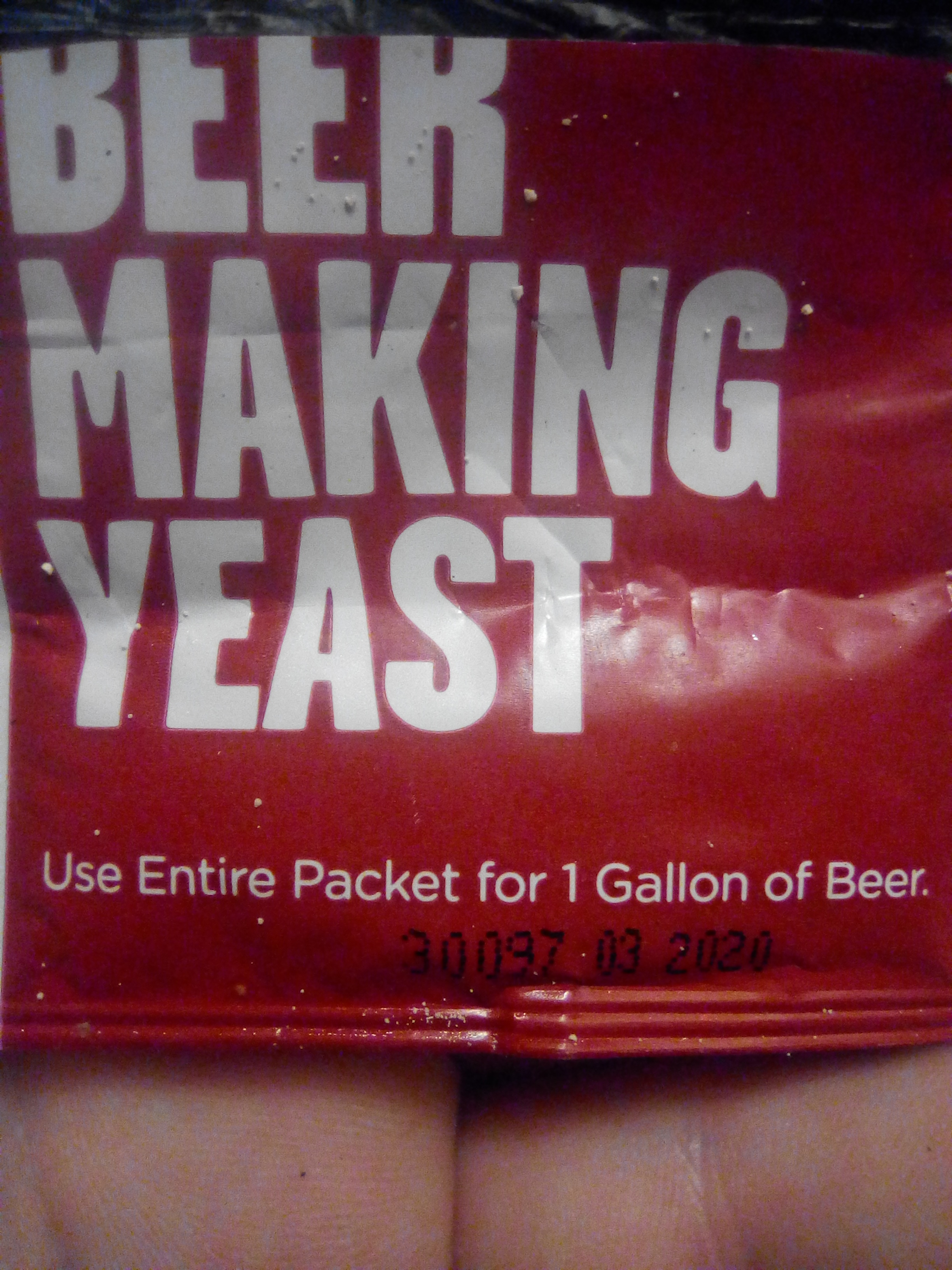

3. What yeast did you use? I looked up the kit but it doesn't actually say what that yeast is. Is there any names on the packet?

4. Bottling takes time, it won't carb in a day or two.

a. In order to bottle, you need to know if you're done fermenting. If you are, you need to add a measured amount of sugar to the beer, bottle it, cap it, and let it sit for 2 weeks at about 70*F to let the yeast do their thing.

Can you provide the above information on the beer?

Yagermyster

Active Member

- Joined

- Nov 23, 2017

- Messages

- 26

- Reaction score

- 0

Let's take a step back for a minute. Before you can bottle anything you need to know if you're done fermenting.

1. Did you check your OG before pitching yeast? If so, what was it?

2. Have you checked your FG to make sure you're done fermenting? What was this number?

3. What yeast did you use? I looked up the kit but it doesn't actually say what that yeast is. Is there any names on the packet?

4. Bottling takes time, it won't carb in a day or two.

a. In order to bottle, you need to know if you're done fermenting. If you are, you need to add a measured amount of sugar to the beer, bottle it, cap it, and let it sit for 2 weeks at about 70*F to let the yeast do their thing.

Can you provide the above information on the beer?

This is the yeast and I don't know how to check the OG or FG I don't even know what OG or FG is

Ok. No worries. Need some more information then.

How long has it been since you pitched yeast?

How long was it sitting at 40*F?

What temp is it sitting at since you warmed it up?

How long has it been since you warmed it up?

As far as OG and FG, that stands for Original Gravity and Final Gravity. This is a measure of how much sugar is in the beer. Original Gravity is the sugar content BEFORE you pitch yeast. Final Gravity is the sugar content AFTER the yeast have finished up and eaten all the sugar that they can.

These are measured with a hydrometer or a refractometer. I recommend getting one or the other. These are essential tools in brewing. This is the only way to know if you're finished fermenting and what your alcohol content is.

Let us know the requested info above and we can help you out more.

How long has it been since you pitched yeast?

How long was it sitting at 40*F?

What temp is it sitting at since you warmed it up?

How long has it been since you warmed it up?

As far as OG and FG, that stands for Original Gravity and Final Gravity. This is a measure of how much sugar is in the beer. Original Gravity is the sugar content BEFORE you pitch yeast. Final Gravity is the sugar content AFTER the yeast have finished up and eaten all the sugar that they can.

These are measured with a hydrometer or a refractometer. I recommend getting one or the other. These are essential tools in brewing. This is the only way to know if you're finished fermenting and what your alcohol content is.

Let us know the requested info above and we can help you out more.

Yagermyster

Active Member

- Joined

- Nov 23, 2017

- Messages

- 26

- Reaction score

- 0

Well I started the 19th that's when I pitched the 1st yeast then the 24th I pitched the 1 tablespoon of yeast (and the thermometer I got with the kit I think something's wrong with it)

But it read at 40°f for like 1day I got it setting with a heating pad around the carboy in it's box it was reading 69°f the last I checked on the 26th and it's been warm since the 24th

But it read at 40°f for like 1day I got it setting with a heating pad around the carboy in it's box it was reading 69°f the last I checked on the 26th and it's been warm since the 24th

Yagermyster

Active Member

- Joined

- Nov 23, 2017

- Messages

- 26

- Reaction score

- 0

Ok. No worries. Need some more information then.

How long has it been since you pitched yeast?

How long was it sitting at 40*F?

What temp is it sitting at since you warmed it up?

How long has it been since you warmed it up?

As far as OG and FG, that stands for Original Gravity and Final Gravity. This is a measure of how much sugar is in the beer. Original Gravity is the sugar content BEFORE you pitch yeast. Final Gravity is the sugar content AFTER the yeast have finished up and eaten all the sugar that they can.

These are measured with a hydrometer or a refractometer. I recommend getting one or the other. These are essential tools in brewing. This is the only way to know if you're finished fermenting and what your alcohol content is.

Let us know the requested info above and we can help you out more.

Oh and is it normal to have stuff in the bottom of the carboy? It looks like yeast or light brown bits there was nothing in it till after it got cold

Last edited:

ancientmariner52

Well-Known Member

That is so normal there's even an ancient name for it: trub, pronounced troob. The light colored part is yeast, the darker stuff is mostly hop residue. Just don't stir it up when you bottle. Perfectly normal, in fact a good sign.

Yagermyster

Active Member

- Joined

- Nov 23, 2017

- Messages

- 26

- Reaction score

- 0

Ah ok that calms my mind on that partThat is so normal there's even an ancient name for it: trub, pronounced troob. The light colored part is yeast, the darker stuff is mostly hop residue. Just don't stir it up when you bottle. Perfectly normal, in fact a good sign.

Yagermyster

Active Member

- Joined

- Nov 23, 2017

- Messages

- 26

- Reaction score

- 0

Would this be a ok first hydrometer

https://www.google.com/aclk?sa=L&ai...7802&wl11=online&wl12=865506784&wl13=&veh=sem

https://www.google.com/aclk?sa=L&ai...7802&wl11=online&wl12=865506784&wl13=&veh=sem

bigdawg86

Well-Known Member

- Joined

- May 1, 2017

- Messages

- 468

- Reaction score

- 197

So you brewed a beer, it got too cold, you warmed it, panicked and then added more sugar and yeast? Then placed a sample in a bottle and expected it to fizz? I am confused. It seems you are kinda lost...

You haven't answered much when people ask what your process was... I googled that kit and it is an all grain kit? That's probably setting you up for problems on your first ever brew.

PLEASE tell me why I spot two cockroaches on your fermentor?!

You haven't answered much when people ask what your process was... I googled that kit and it is an all grain kit? That's probably setting you up for problems on your first ever brew.

PLEASE tell me why I spot two cockroaches on your fermentor?!

Yagermyster

Active Member

- Joined

- Nov 23, 2017

- Messages

- 26

- Reaction score

- 0

Well bug prob in my storage building and the beer kit is this

I brought it in to my bed room where I can keep an eye on it

I brought it in to my bed room where I can keep an eye on it

Yagermyster

Active Member

- Joined

- Nov 23, 2017

- Messages

- 26

- Reaction score

- 0

So you brewed a beer, it got too cold, you warmed it, panicked and then added more sugar and yeast? Then placed a sample in a bottle and expected it to fizz? I am confused. It seems you are kinda lost...

You haven't answered much when people ask what your process was... I googled that kit and it is an all grain kit? That's probably setting you up for problems on your first ever brew.

PLEASE tell me why I spot two cockroaches on your fermentor?!

And yes I'm kinda lost it's my first time brewing and I'm answering questions as good as I can if it's a question I've not answered then point it out I don't have a hydrometer so idk the OG and idk what the FG post to be

ancientmariner52

Well-Known Member

It's all good. Some folks don't remember what it was like starting out, especially without a local mentor to set you straight. You're just swingin' in the dark, hopin' somethin' connects. Try to have patience with us if we sound a little sharp sometimes, and I hope we will have patience with you.

The cockroaches are really bad news, though.

The cockroaches are really bad news, though.

bigdawg86

Well-Known Member

- Joined

- May 1, 2017

- Messages

- 468

- Reaction score

- 197

Well if that kit was all grain, that may be part of your problem. Temperatures will make or break a all grain brew. I have about 15 extract brews under my belt and only did my first all grain this week. If for some reason this beer is a dumper, I would highly recommend getting a extract kit and learn the basics. Learn how to make measurements, quality control, the works. Once you learn the basics, you can then improve your extract beer quality by adding fermentation temperature control and other things... That doesn't help you with this current brew, but I think that you need to slow down and get some foundational experience. That's my 2 cents.

Yagermyster

Active Member

- Joined

- Nov 23, 2017

- Messages

- 26

- Reaction score

- 0

Well if that kit was all grain, that may be part of your problem. Temperatures will make or break a all grain brew. I have about 15 extract brews under my belt and only did my first all grain this week. If for some reason this beer is a dumper, I would highly recommend getting a extract kit and learn the basics. Learn how to make measurements, quality control, the works. Once you learn the basics, you can then improve your extract beer quality by adding fermentation temperature control and other things... That doesn't help you with this current brew, but I think that you need to slow down and get some foundational experience. That's my 2 cents.

K I can use all the cents I can get

And yes it was all grain I believe it has stuff that looked like oatmeal and some dried hops in a air sealed bag

Last edited:

Yagermyster

Active Member

- Joined

- Nov 23, 2017

- Messages

- 26

- Reaction score

- 0

It's all good. Some folks don't remember what it was like starting out, especially without a local mentor to set you straight. You're just swingin' in the dark, hopin' somethin' connects. Try to have patience with us if we sound a little sharp sometimes, and I hope we will have patience with you.

The cockroaches are really bad news, though.

It's all good I wasn't sure if I missed someone's question or not I'm just hoping this turns out right or drinkable at the least the taste I had was pretty good tasted kinda like whiskey

and the bugs yep that's why I moved it I said I'm sure that's not a good thing to have around it

ancientmariner52

Well-Known Member

You're on your way!

Yagermyster

Active Member

- Joined

- Nov 23, 2017

- Messages

- 26

- Reaction score

- 0

You're on your way!

Yay!! So it might just turn out ok

If my calculations are right it would be ready to bottle on December the 3rd or would I have to wait longer since I added that 1 tablespoon of yeast? :/

bigdawg86

Well-Known Member

- Joined

- May 1, 2017

- Messages

- 468

- Reaction score

- 197

If my calculations are right it would be ready to bottle on December the 3rd or would I have to wait longer since I added that 1 tablespoon of yeast?

Well the beer will be done when the yeast is done. Your second addition of yeast will not influence anything. When yeast runs out of fermentable sugars, then fermentation is complete. If you have the same hydrometer reading 2-3 days straight then you are done... if you don't have a hydrometer then I would at least wait 10-14 days.

When you go to bottle remember you have to add dextrose to the bottling bucket so the yeast have something to munch on... that's how carbonation is achieved. I assume your kit has a predetermined amount of bottling sugar included. Just follow the directions.

Yagermyster

Active Member

- Joined

- Nov 23, 2017

- Messages

- 26

- Reaction score

- 0

Well the beer will be done when the yeast is done. Your second addition of yeast will not influence anything. When yeast runs out of fermentable sugars, then fermentation is complete. If you have the same hydrometer reading 2-3 days straight then you are done... if you don't have a hydrometer then I would at least wait 10-14 days.

When you go to bottle remember you have to add dextrose to the bottling bucket so the yeast have something to munch on... that's how carbonation is achieved. I assume your kit has a predetermined amount of bottling sugar included. Just follow the directions.

Dextrose?? And no it just had grain and yeast and hold on I'll take a picture

BigCrazyAl

Well-Known Member

Table sugar works fine as well. You're essentially adding a controlled amount of fermentable sugar to the batch right before bottling. This will allow for additional fermentation within the bottle to an expected CO2 volume or pressure. There are calculators online that will tell you how much to add for many different fermentables like honey, white table sugar, corn sugar, etc.

Yes, you're missing the dextrose, or corn sugar, that is needed for carbonation. To carbonate a bottled beer, you add a measured amount of sugar to a measured amount of water, boil it so the sugar dissolves, cool it down close to the temperature of your beer, dump the sugar/water into your bottling bucket, and rack your beer on top of that to mix it. Then you bottle it all and let it sit for 2 weeks at room temperature and the yeast left in the beer will eat that sugar and create carbonation. Here is the link to an easy calculator to determine how much sugar you need.

https://www.brewersfriend.com/beer-priming-calculator/

Like BigCrazyAl stated, you can use table sugar as well if you can't find corn sugar.

https://www.brewersfriend.com/beer-priming-calculator/

Like BigCrazyAl stated, you can use table sugar as well if you can't find corn sugar.

Yagermyster

Active Member

- Joined

- Nov 23, 2017

- Messages

- 26

- Reaction score

- 0

Ah ok so now just to wait for it to be ready to bottle

applescrap

Be the ball!

Welcome to this fascinating and interesting Hobby. Yeah, there's a good chance it will turn out. Whatever happens chalk it up to having some fun learning a new skill and of course make more beer! No matter what happens don't get discouraged and keep on with it as your skill and knowledge will grow.Yay!! So it might just turn out ok

If my calculations are right it would be ready to bottle on December the 3rd or would I have to wait longer since I added that 1 tablespoon of yeast? :/

Yagermyster

Active Member

- Joined

- Nov 23, 2017

- Messages

- 26

- Reaction score

- 0

Welcome to this fascinating and interesting Hobby. Yeah, there's a good chance it will turn out. Whatever happens chalk it up to having some fun learning a new skill and of course make more beer! No matter what happens don't get discouraged and keep on with it as your skill and knowledge will grow.

Thank you and will do I like cooking and all ways looking for stuff to do

OP, may I also suggest you do some reading. John Palmer's How to brew (available free online) is a great place to start. Then the terms OG, FG, SG, fermentation temperatures, hydrometer, and such will make sense to you. This book (first edition only online, you can find later editions in print everywhere) is just about every homebrewer's bible and covers everything you need to know, for now. And bookmark Home Brew Talk!!

Similar threads

- Replies

- 1

- Views

- 686

- Replies

- 6

- Views

- 951

- Replies

- 4

- Views

- 254

- Replies

- 2

- Views

- 541