Hello everyone, I ended up buying two March 809 pumps for my Brutus stand (thanks for all who chimed in on my pump model question). I have a question about which is better, using a ball valve, a gate valve, or a globe valve on the pumps for flow control. I have read many posts of people using the Brutus setups saying that it takes some time to fine tune and match the flow rate on the mash tun and the hot liquor tank so they are identical, when using ball valves on the March pumps.

Since flow control is important and matching the flow rate in both vessels is paramount I was wondering if a gate valve is better. I am thinking this since you have more control over the openings in the valve in smaller increments that you can dial in with the gate valve, (and repeat and match on the other pump). If anyone has used these valves or better has used both I would like your opinion.

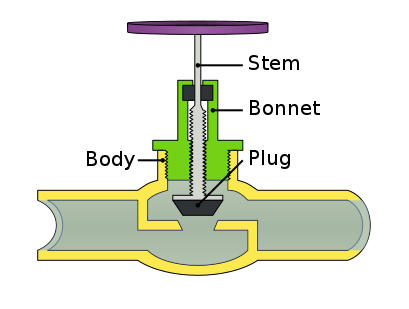

Also is the gate valve a magnet for gunk, wort, hops etc, to build up or get caught in the valve mechanism? Is it harder to flush out or keep clean? Or is a ball valve the way to go for simple functionality and for being hassel free? Is a globe valve another way to go, or not good for what I need it to do?

I am trying to use all stainless steel parts for my system. I found these two valves in stainless steel, check them out and let me know what you think:

http://www.discovervalve.com/102232/ss_gate_valve_thd.html

http://www.discovervalve.com/102250/ss_globe_valve_thd.html

(Incidentally I bought my 1/2 inch stainless steel needle valves from them for better flame control on my Banjo burners and they were great quality and were an excellent price).

Here is the link: http://www.discovervalve.com/101005/needle_valve_6k_ss.html

I appreciate any feed back and of course I can always use a ball valve if these other types of valves are not up to the task.

Since flow control is important and matching the flow rate in both vessels is paramount I was wondering if a gate valve is better. I am thinking this since you have more control over the openings in the valve in smaller increments that you can dial in with the gate valve, (and repeat and match on the other pump). If anyone has used these valves or better has used both I would like your opinion.

Also is the gate valve a magnet for gunk, wort, hops etc, to build up or get caught in the valve mechanism? Is it harder to flush out or keep clean? Or is a ball valve the way to go for simple functionality and for being hassel free? Is a globe valve another way to go, or not good for what I need it to do?

I am trying to use all stainless steel parts for my system. I found these two valves in stainless steel, check them out and let me know what you think:

http://www.discovervalve.com/102232/ss_gate_valve_thd.html

http://www.discovervalve.com/102250/ss_globe_valve_thd.html

(Incidentally I bought my 1/2 inch stainless steel needle valves from them for better flame control on my Banjo burners and they were great quality and were an excellent price).

Here is the link: http://www.discovervalve.com/101005/needle_valve_6k_ss.html

I appreciate any feed back and of course I can always use a ball valve if these other types of valves are not up to the task.

If you buy these same valves,

If you buy these same valves,