Why didn't you try to use it Yoop?

I get it, you must be one of those "rich city folk"

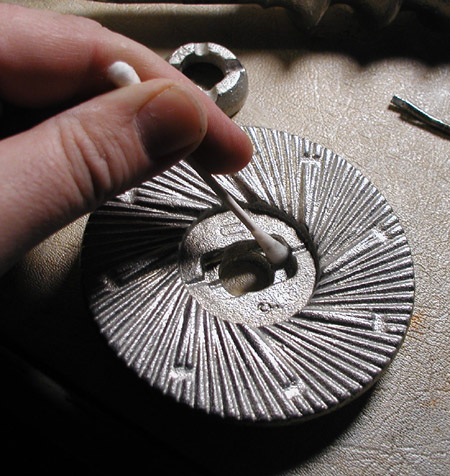

I thought about getting a roller mill, but with 83% efficiency why change

I never used it because I'm not smart enough to make a hopper, and adjust the settings, I guess. I used one at a LHBS once, and I tore the **** out of the husks and got 58% efficiency besides. I decided I wasn't smart enough to even try.

I'm glad it can be used- and I have a new barley crusher, so I'm happy. And Revvy's happy. We should have a group hug!