theichthus

Well-Known Member

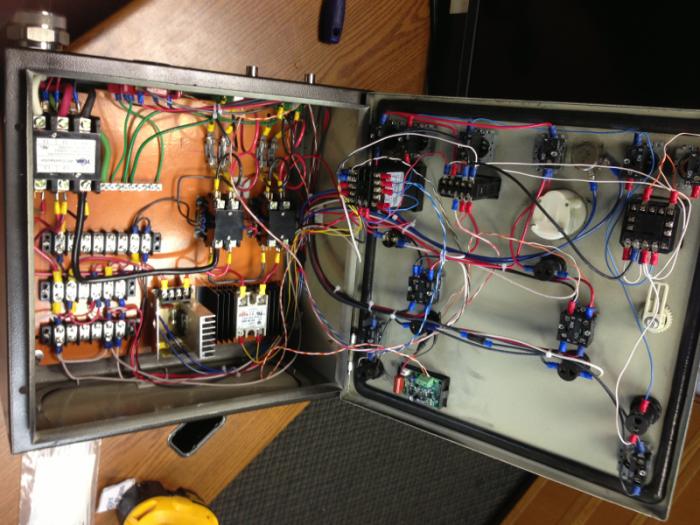

I finally have made all of the large purchases for my Kal mutation and will document progress here as well as ask for lots of help.

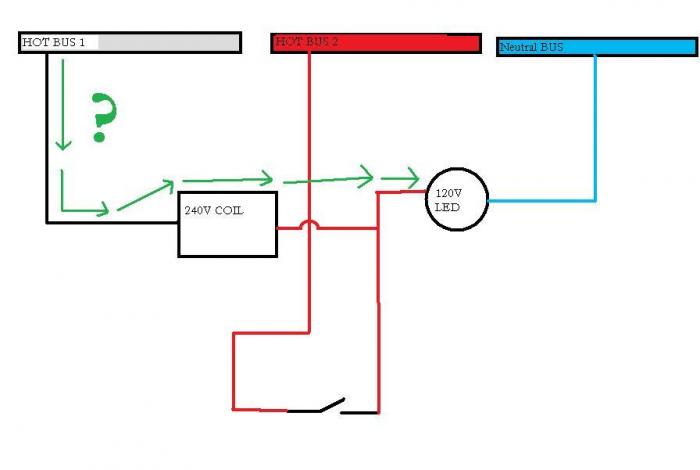

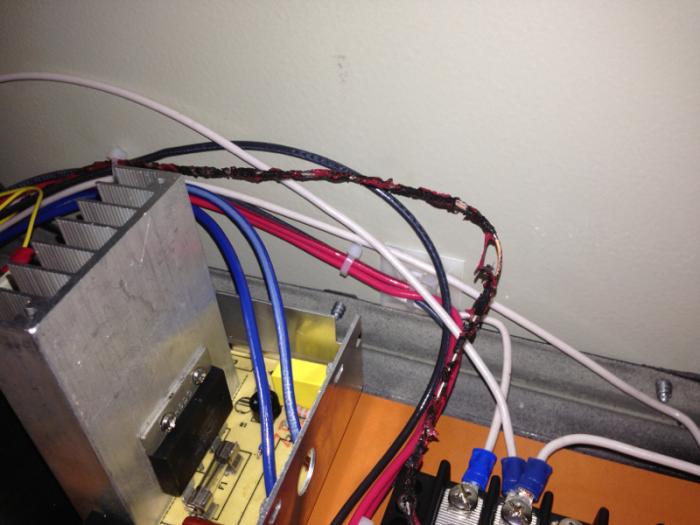

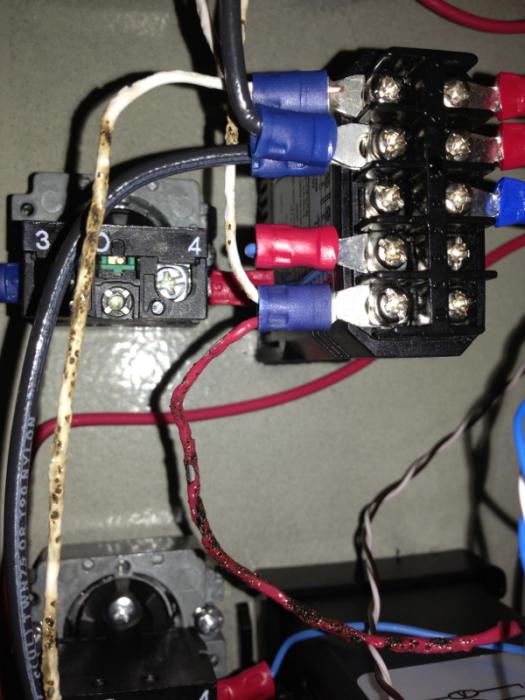

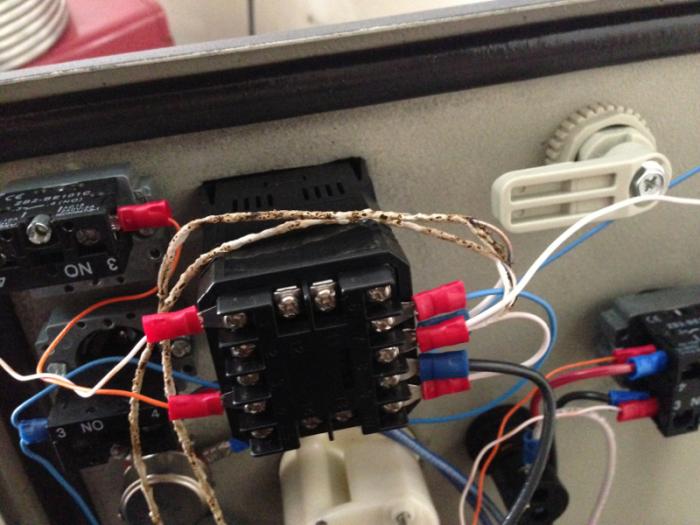

My rig differs in that I am building a panel capable of firing two 5500W elements simultaneously. Minor differences are that all my relay coils and my pumps are 240V so my wiring will differ significantly.

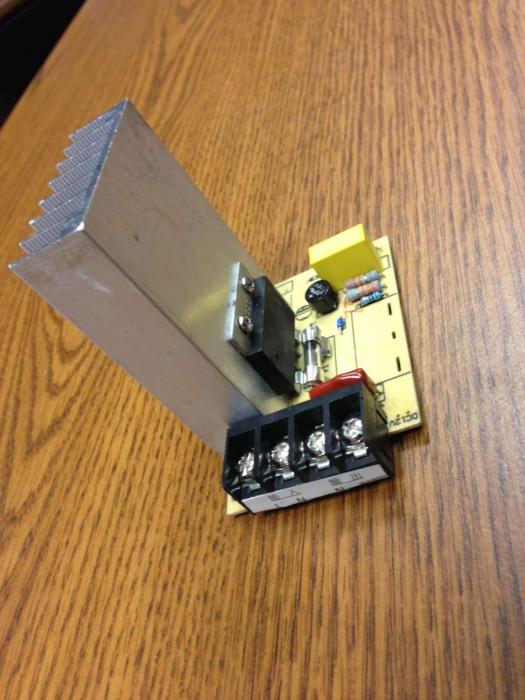

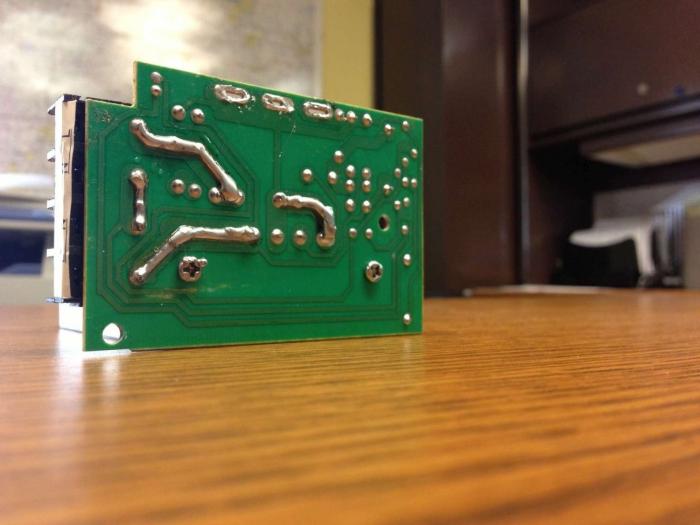

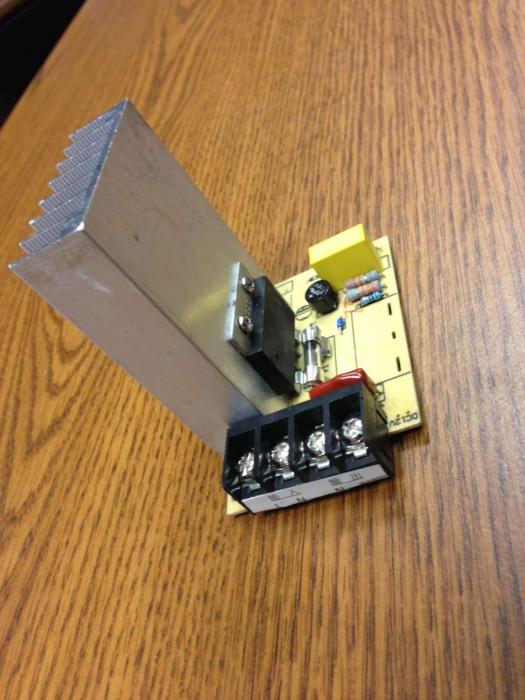

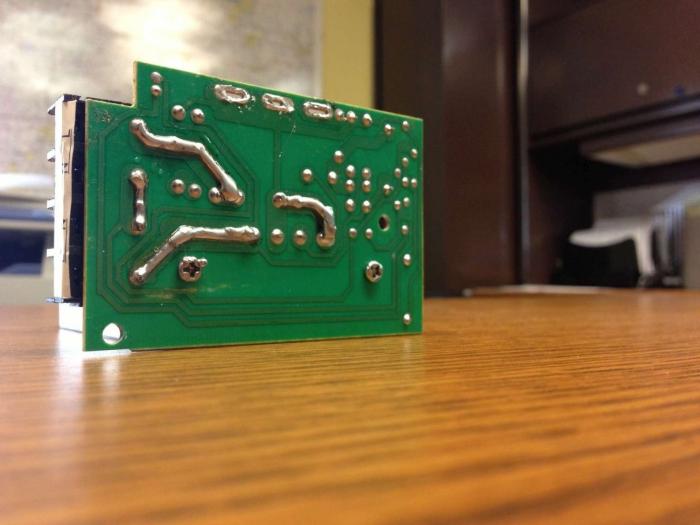

The last change is that I am hoping to use the pictured 6500W thyristor from ebay to control my Boil Kettle. In trying to trim expenses where I could, the thermocouple and PID seemed unnecessary. Plus I wanted something to be unique.

I am confused that is has 4 terminals. Do you think i run both legs throught it? I unsoldered the potentiometer, because I didn't have room to mount the whole unit to the door of the panel.

Has anyone used one of these? Can anyone offer advice? Thanks. I also included my planned component placement for the heck of it. Happy for advice there too. Thanks!

My rig differs in that I am building a panel capable of firing two 5500W elements simultaneously. Minor differences are that all my relay coils and my pumps are 240V so my wiring will differ significantly.

The last change is that I am hoping to use the pictured 6500W thyristor from ebay to control my Boil Kettle. In trying to trim expenses where I could, the thermocouple and PID seemed unnecessary. Plus I wanted something to be unique.

I am confused that is has 4 terminals. Do you think i run both legs throught it? I unsoldered the potentiometer, because I didn't have room to mount the whole unit to the door of the panel.

Has anyone used one of these? Can anyone offer advice? Thanks. I also included my planned component placement for the heck of it. Happy for advice there too. Thanks!