r8rphan

Well-Known Member

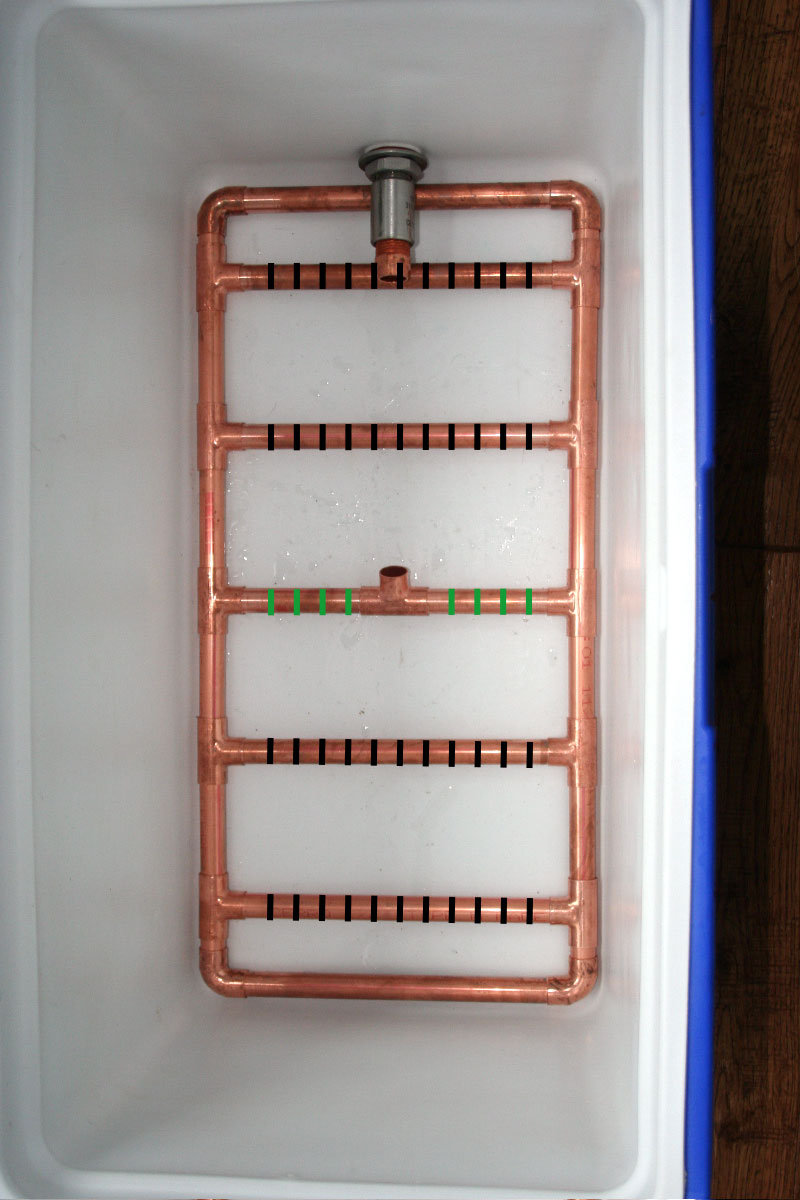

.. for my mash tun.. Got all the 90's and Tee's laid out, cutting the tubing...

Couple questions.. How wide should the slits be? I know many people use hack saws, but I was hoping to use my dremel tool or peanut grinder with a cutoff wheel...

The cut off wheels I have for my peanut grinder are 3/64" thick.. Would probably make a cut that is 1/16".. I think the dremel blade is slightly thinner yet...

Also, I plan to use a short piece of 1/2" silicone tubing to connect the manifold to the outlet.. Can I use 'nylon' barbs? Or do they have to be stainless or brass? Will the nylon barbs handle the heat? With this set up, I'm thinking I won't need hose clamps.. or should I use them anyways?

Couple questions.. How wide should the slits be? I know many people use hack saws, but I was hoping to use my dremel tool or peanut grinder with a cutoff wheel...

The cut off wheels I have for my peanut grinder are 3/64" thick.. Would probably make a cut that is 1/16".. I think the dremel blade is slightly thinner yet...

Also, I plan to use a short piece of 1/2" silicone tubing to connect the manifold to the outlet.. Can I use 'nylon' barbs? Or do they have to be stainless or brass? Will the nylon barbs handle the heat? With this set up, I'm thinking I won't need hose clamps.. or should I use them anyways?