llenrocs

Well-Known Member

I am finally getting around to posting photos of the cider press that I built this year. I made 50 gallons of cider this year, mostly with donated apples. Varieties used: Winesap, Jonathon, Red Delic., Golden Delic., Granny Smith and 3 unknown red varieties.

Some info about the press:

The frame was constructed of 4x6 beams from a barn that I tore down a few years ago. The uprights were notched and the frame was bolted together using 1/2" threaded rod.

The runoff table is a piece of scrap laminate countertop with 3" pine side pieces. The pine boards were sealed with polyurethane & then nailed to the countertop. The drain is a 3/4" copper coupling. Everything was sealed up with food grade silicon.

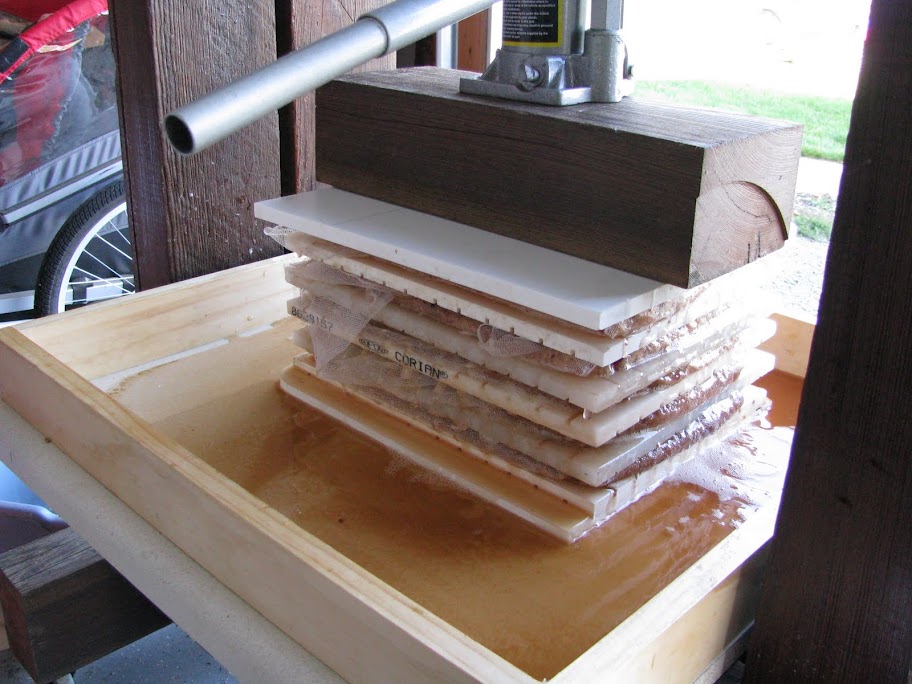

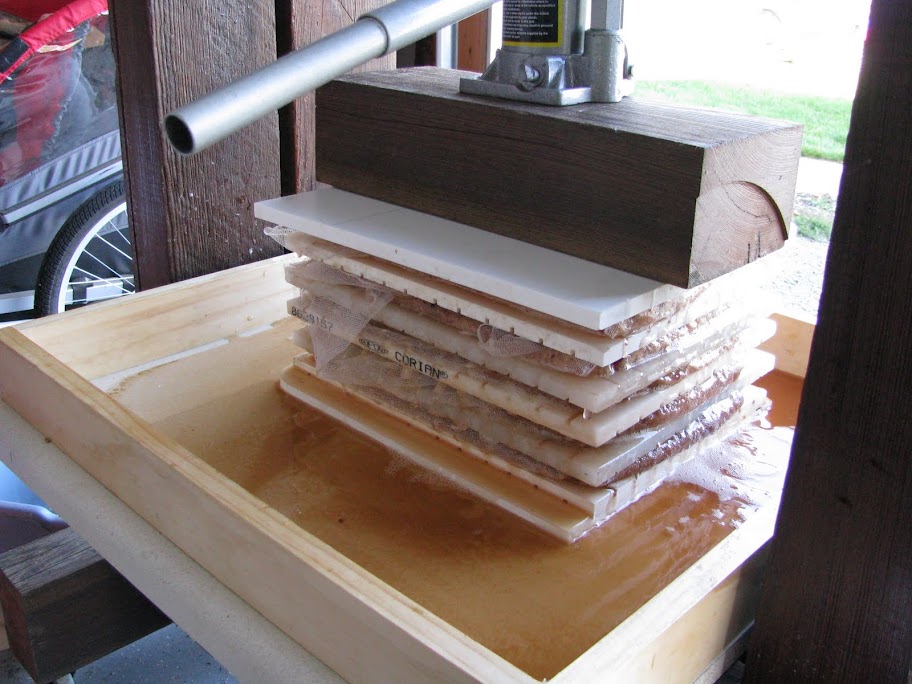

The press racks are scrap corian pieces 10"x12". I grooved both sides of the racks on the table saw for better extraction. I will be getting large racks (15"x18") before pressing next year to improve my yield/press. The press cloths are just nylon netting material; very cheap but only good for 1 season as they tear pretty easy.

I press 5 layers of apples (about 1/2 bushel) at a time and get 2 to 2.5 gallons of juice each time. This should double next year with the larger racks.

The press mechanism is a 6-ton hydraulic bottle jack. The frame does not make so much as a creak with the full 6 tons of force applied. I press against a sacrificial 2x4 on top so I don't damage my cross beam.

The grinder is a 1/2 hp garbage disposal mounted in another piece of scrap countertop. This works extremely well an creates a nearly perfect grind for pressing.

Total breakdown of costs:

Garbage disposal: $50

Bottle Jack: $15

Corian pieces: $25 (ebay, includes shipping)

Counterop pieces: $2

Misc hardware: $30

Of the 50 gallons that I pressed, I gave away about 35 gallons to friends and family. I also made 5 gallons of Graff and will likely kick off a 3 gallon batch of straight hard cider also. I measured the SG on last batch and came up with 1.055, which should make a nice hard cider without any sugar added.

I have 40+ apple trees on my property, but only 4 of them are bearing apples now. I plan to start producing cider to sell in about 5 years when the rest of my trees are producing apples.

Overall, this has been a very satisfying late summer/fall project.

Any comments/suggestions are welcome.

Some info about the press:

The frame was constructed of 4x6 beams from a barn that I tore down a few years ago. The uprights were notched and the frame was bolted together using 1/2" threaded rod.

The runoff table is a piece of scrap laminate countertop with 3" pine side pieces. The pine boards were sealed with polyurethane & then nailed to the countertop. The drain is a 3/4" copper coupling. Everything was sealed up with food grade silicon.

The press racks are scrap corian pieces 10"x12". I grooved both sides of the racks on the table saw for better extraction. I will be getting large racks (15"x18") before pressing next year to improve my yield/press. The press cloths are just nylon netting material; very cheap but only good for 1 season as they tear pretty easy.

I press 5 layers of apples (about 1/2 bushel) at a time and get 2 to 2.5 gallons of juice each time. This should double next year with the larger racks.

The press mechanism is a 6-ton hydraulic bottle jack. The frame does not make so much as a creak with the full 6 tons of force applied. I press against a sacrificial 2x4 on top so I don't damage my cross beam.

The grinder is a 1/2 hp garbage disposal mounted in another piece of scrap countertop. This works extremely well an creates a nearly perfect grind for pressing.

Total breakdown of costs:

Garbage disposal: $50

Bottle Jack: $15

Corian pieces: $25 (ebay, includes shipping)

Counterop pieces: $2

Misc hardware: $30

Of the 50 gallons that I pressed, I gave away about 35 gallons to friends and family. I also made 5 gallons of Graff and will likely kick off a 3 gallon batch of straight hard cider also. I measured the SG on last batch and came up with 1.055, which should make a nice hard cider without any sugar added.

I have 40+ apple trees on my property, but only 4 of them are bearing apples now. I plan to start producing cider to sell in about 5 years when the rest of my trees are producing apples.

Overall, this has been a very satisfying late summer/fall project.

Any comments/suggestions are welcome.