newdamage1

Well-Known Member

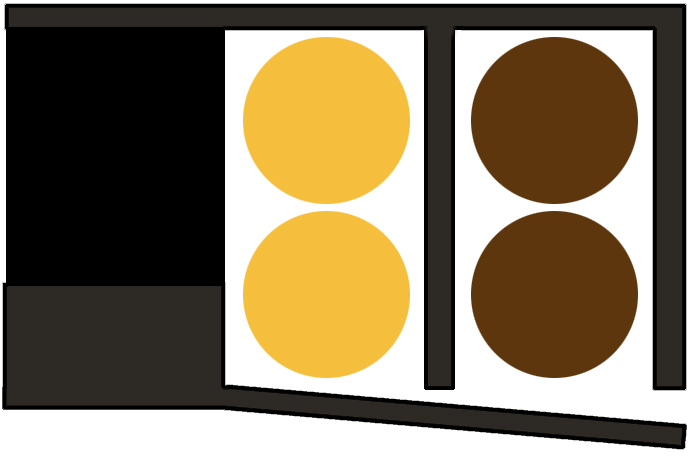

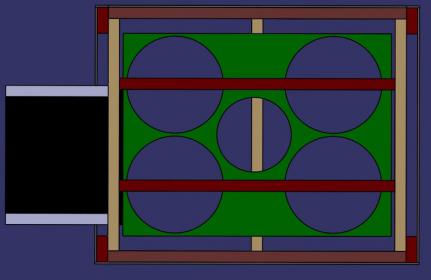

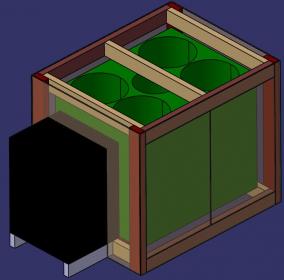

hiya folks, I just picked up a 2.8cuft mini-fridge, and I would like to convert it to a dual chamber/zone fermenter. I'm looking at storage for 2 six gallon carboys per zone.

The long term intention is to have and ale & lager side, Plus, enough room on the lager side for a few corny kegs down the road.

The question is, how large an area do you think I can go with this type of unit (Emerson cr282b)? The space I'm looking to use is 26"w X 48"h X 36"t.

Ive seen people chill some pretty big area with a A/C window unit, so I'm guessing this will work, just figured I'd run it by you fine folks.

The long term intention is to have and ale & lager side, Plus, enough room on the lager side for a few corny kegs down the road.

The question is, how large an area do you think I can go with this type of unit (Emerson cr282b)? The space I'm looking to use is 26"w X 48"h X 36"t.

Ive seen people chill some pretty big area with a A/C window unit, so I'm guessing this will work, just figured I'd run it by you fine folks.