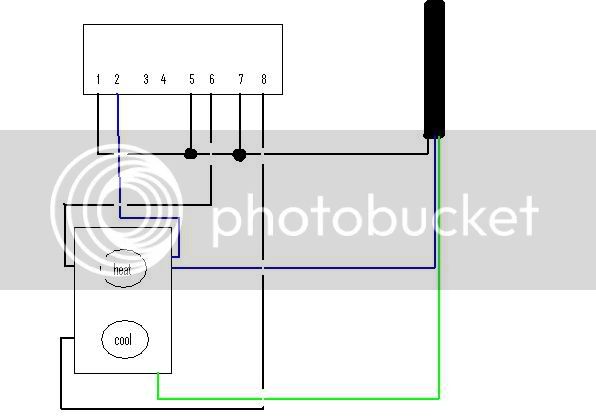

I think he mentioned that he is heating currently, so that is why he is setting it higher.I notice that it cools to SP, then shuts off the compressor, which then lets the temp rise to SP+offset, then kicks on the compressor.

So with a 20* SP and 0.5* offset, you average at 20.25* in the chamber.

If you really want to hold at 20*, you need to set your temp to 19.75 with an offset of 0.5. Or to 19.7 with an offset of 0.6, or 19.8 with an offset of 0.4. You get the idea.

If you are really going to get that anal about it, it isn't a simple avg even with steady ambient temps. It will be some kind of logarithmic or exponential decay/increase waveform. It really just isn't that critical with proper probe placement that allows a .5C diff. Maybe a bit of compensation could be justified in winter and summer when it is purely heating or cooling, but there are meds that can help with that.