As requested, pictures are below. The first two are the spacers I used under my kettles. I tried it without them, and the 2inch tubing choked the flame too much even with no heat shields on the burners. These were more of an after-thought. They work really well though. Painted them with the high temp black barbecue spray paint at the big blue store. I like that they're removable and I can easily access the burners from the top for cleaning.

Next up is the pivot for the control panel. As you can see there's just a hole drilled through the top, and I happened to have a long socket extension I wasn't using, so I dropped that in place. Plans were to use a bolt...I may get around to that some day. All wiring is passed through quick disconnects at this junction and the entire control arm can be taken off in about 10 seconds. This makes it easy to travel with. I take my stand to a local brewery on occasion. Keeps the control panel dry in the rain.

As you can see the control arm is rounded so it can rotate 180 degrees.

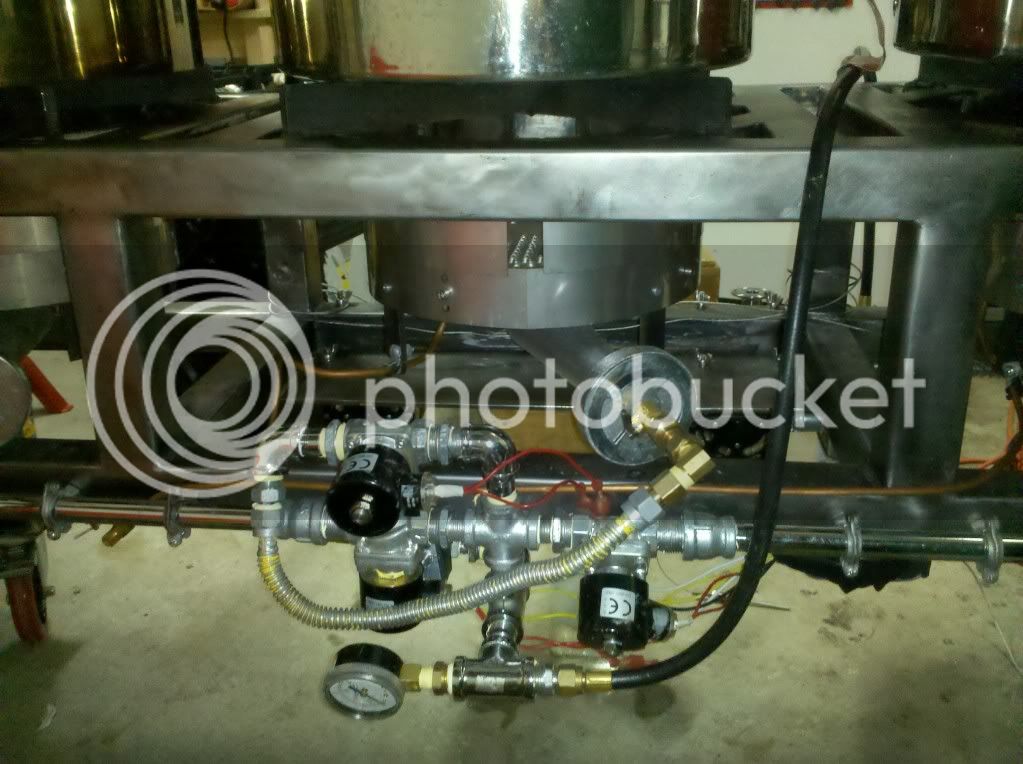

Just in case anyone wanted to see, this is what's in the back. The solenoids for the gas manifold. These are what the auber instruments controllers use to turn on and off the gas to the burners, and one for the pilots.

I have been debating using keggles or the ones from stout tanks as well. After seeing your setup I'm going to go that route and sell the kegs I have sitting around. A very nice setup!

Yes, I liked the keggles I had, but when I priced the cost of having someone weld sanitary welds in all the places I wanted, and then acquiring the necessary parts to go to tri-clamp fittings it's actually about the same price as getting these...and you'd still only have a bunch of welded kegs with less capacity. Sure I could have done something simpler, but I wanted to be done with worrying about my system.

I still need to add a plate chiller to it. Looking at the Duda Diesel plate chillers, but if someone knows of a place to get tri-clamp fittings on their chiller without threads, let me know!