thelema5

Well-Known Member

I've been brewing ciders for about a year, and recently tried a ginger cider at a local craft brew tasting which really piqued my interest. I thought a honey-ginger cider would be lovely, but I was unable to find many recipes online which really approached what I was looking for.

SO, I put this recipe together from several sources, and I'm hoping for the best. It's only been in primary for a few hours as I write this, so I'll have to update later with how everything came out!

I'm posting this recipe as a step-by-step tutorial for people who are new to cider-making, so some information may be obvious to others. Also, I've never fermented honey before (I think this is technically a ginger cyser) so there's a bit of a learning curve for me, as well.

First, here is the equipment you'll need to get started:

From left to right, front to back:

(1) five gallon food-grade plastic bucket with an air-tight lid

(1) auto-siphon

(1) carboy, 6 gallon in this case- 5 is fine too

(1) Large ladle

(1) kitchen scale

(1) candy thermometer

(1) 4 quart stainless steel pot

(1) hydrometer

(1) large funnel

(1) rubber bung w/ hole for airlock

(1) airlock

(1) bottle antibacterial detergent

(1) measuring spoon

(1) bottle Star-San

The ingredients you'll need are:

(6) gallons apple juice (I'm using what most people have access to: store-bought, preservative free and pasteurized)

(3) pounds wildflower honey

(3) pounds white sugar

(2) ounces fresh ginger

(1) Tablespoon Malic Acid

(1) package Mangrove Jack's Cider Yeast

(6) tea bags (boiled in 2 cups water, added to secondary)

Method:

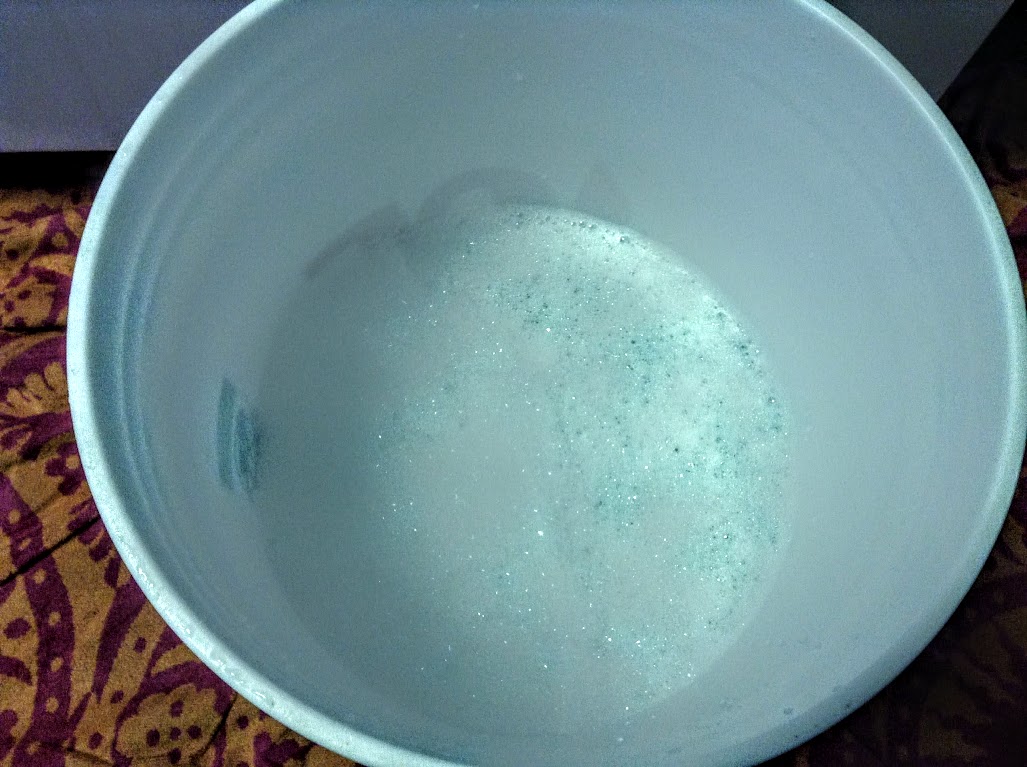

Prepare a sanitizer solution in your clean 5 gal. bucket with 2.5 gal. water and 3 teaspoons of "star-san". This solution will sterilize everything we use throughout this process, and will later be sealed and reserved for reuse at racking.

Then, wash and sanitize the stainless steel pot:

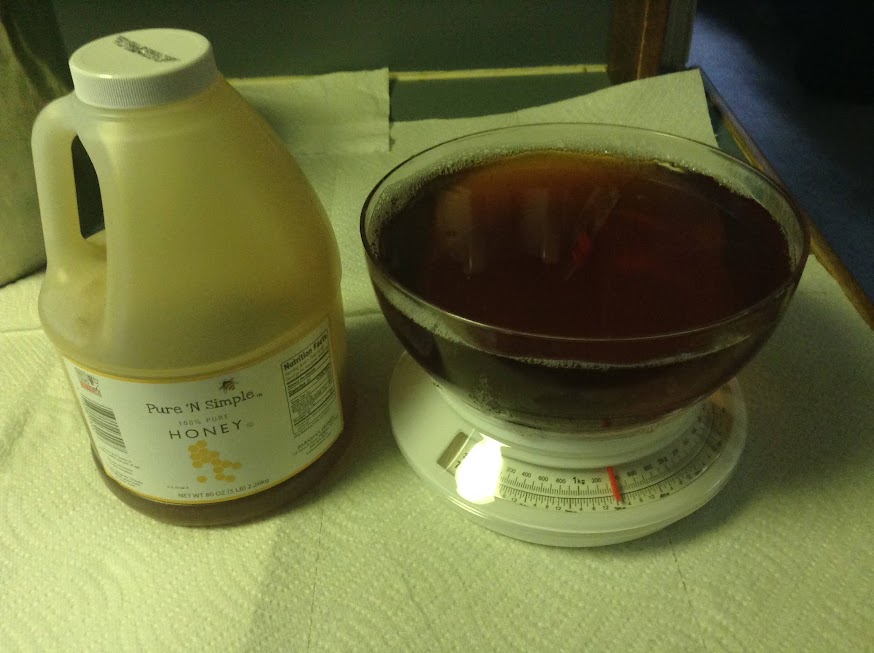

Next, measure out three pounds of honey:

Add the honey to the pot. Next, weight out 3 pounds of white sugar:

Add the white sugar to the pot, also. Then, peel and dice 2 ounces of fresh ginger.

Add the ginger to the pot as well. This is what you'll have.

Next, add 96 ounces of apple juice to this pot to dissolve the honey and sugar during the pasteurization process. Here, I'm using store-bought pasteurized preservative free juice because nearly everyone has access to it. You can blend your own fresh juice, but I would suggest pasteurizing it all.

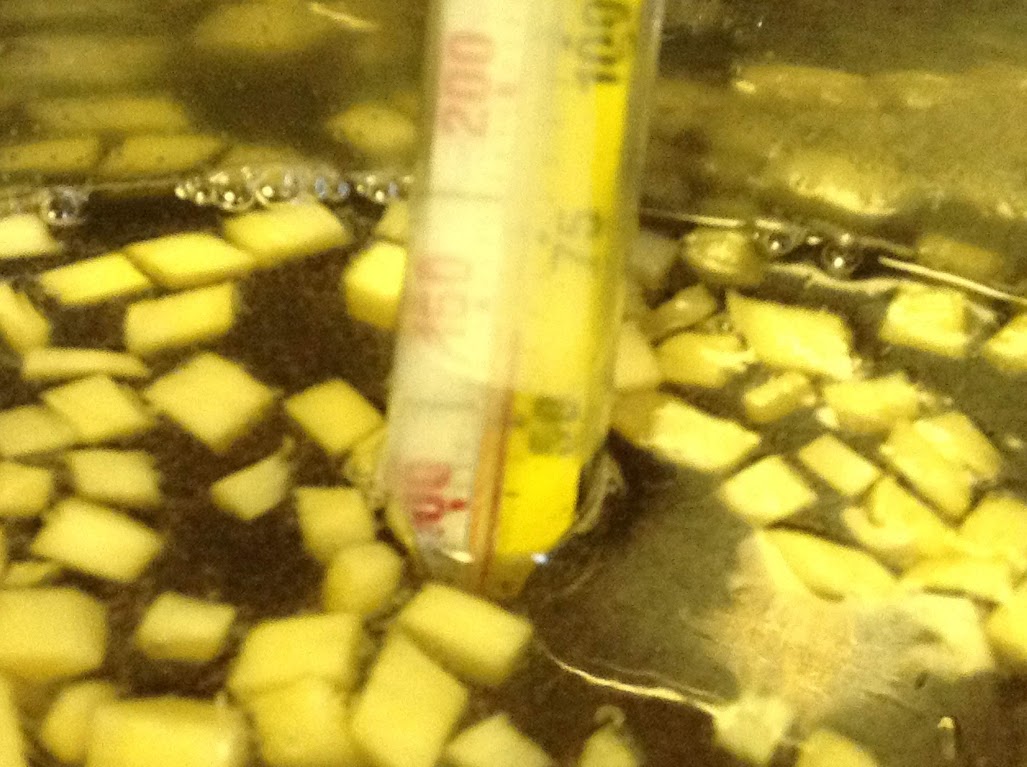

Now, you'll want to bring this all to 150 degrees and hold it there for 30 minutes. Stir as the ingredients in the pot come up to temperature, and regularly throughout the heating time to prevent scorching.

Using a candy thermometer, monitor the pasteurization temperature and maintain it at 150 degrees for 30 minutes to kill off any wild yeasts and bacteria. Hotter temperatures will cook the ingredients and alter the flavors, but cooler temperatures won't properly sanitize them.

While monitoring the the temperature of the pot, begin to clean and sanitize the rest of your equipment. First, wash everything very well with hot water and antibacterial soap.

Then, rinse all of the equipment well with the star-san solution in the bucket, soaking each item. Use the auto-siphon to fill the carboy, and slosh it around until every spot is sterile. Make sure the solution is in contact with every surface for at least three minutes.

Once the carboy is sanitized, you can begin adding juice using your sanitized funnel. Just add about a gallon at this point, so the hot "must" has a heat sink when it's added, and so its sugars will become more dilute.

Now, add 1 tablespoon of Malic Acid to the heated must- this is to compensate for using store-bought sweet juice rather than fresh cider apples. Malic acid is apple acid, so this will make the cider more tart.

Once the heated must has undergone 30 minutes of pasteurization, ladle it into the prepared carboy

Once all of the heated must is added to the carboy, add the remaining apple juice, until you reach nearly to the neck of the carboy.

Next, dry pitch the yeast into the carboy and funnel, and top off the carboy, making sure to rinse the yeast in the funnel into the carboy. Leave at least three inches of headspace in the carboy to allow for some foaming during the fermentation.

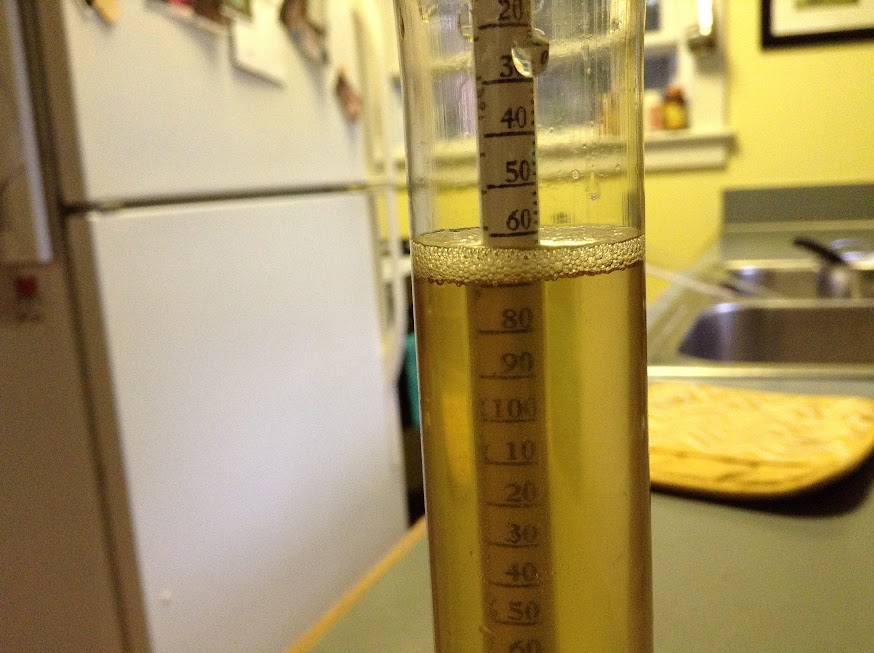

This completes the first phase of this honey-ginger cider recipe; now, we'll use the auto-siphon to draw off a small volume of must for analysis

The initial gravity reads 1.064, which gives us a potential ABV of about 8%. I expect that it will ferment out a bit lower, maybe 7%, due to suspended solids present in the honey.

Finally, seal the carboy with a sanitized bung, and set an airlock filled with 90 grain alcohol firmly into the center of it. We don't want any wild nasties to wind up in the mix.

This is what the final brew looks like now that it's set down. The ginger seems to have settled, and the yeast is in uniform suspension. I hope to update this thread in 24 hours with photos of lovely little bubbles.

UPDATE: 24 hours into primary, the yeast is already hard at work: The airlock is bubbling away at a steady clip of 1 CO2 release every 3 seconds. I'll update again when we rack it down for secondary in about 3-4 weeks.

SO, I put this recipe together from several sources, and I'm hoping for the best. It's only been in primary for a few hours as I write this, so I'll have to update later with how everything came out!

I'm posting this recipe as a step-by-step tutorial for people who are new to cider-making, so some information may be obvious to others. Also, I've never fermented honey before (I think this is technically a ginger cyser) so there's a bit of a learning curve for me, as well.

First, here is the equipment you'll need to get started:

From left to right, front to back:

(1) five gallon food-grade plastic bucket with an air-tight lid

(1) auto-siphon

(1) carboy, 6 gallon in this case- 5 is fine too

(1) Large ladle

(1) kitchen scale

(1) candy thermometer

(1) 4 quart stainless steel pot

(1) hydrometer

(1) large funnel

(1) rubber bung w/ hole for airlock

(1) airlock

(1) bottle antibacterial detergent

(1) measuring spoon

(1) bottle Star-San

The ingredients you'll need are:

(6) gallons apple juice (I'm using what most people have access to: store-bought, preservative free and pasteurized)

(3) pounds wildflower honey

(3) pounds white sugar

(2) ounces fresh ginger

(1) Tablespoon Malic Acid

(1) package Mangrove Jack's Cider Yeast

(6) tea bags (boiled in 2 cups water, added to secondary)

Method:

Prepare a sanitizer solution in your clean 5 gal. bucket with 2.5 gal. water and 3 teaspoons of "star-san". This solution will sterilize everything we use throughout this process, and will later be sealed and reserved for reuse at racking.

Then, wash and sanitize the stainless steel pot:

Next, measure out three pounds of honey:

Add the honey to the pot. Next, weight out 3 pounds of white sugar:

Add the white sugar to the pot, also. Then, peel and dice 2 ounces of fresh ginger.

Add the ginger to the pot as well. This is what you'll have.

Next, add 96 ounces of apple juice to this pot to dissolve the honey and sugar during the pasteurization process. Here, I'm using store-bought pasteurized preservative free juice because nearly everyone has access to it. You can blend your own fresh juice, but I would suggest pasteurizing it all.

Now, you'll want to bring this all to 150 degrees and hold it there for 30 minutes. Stir as the ingredients in the pot come up to temperature, and regularly throughout the heating time to prevent scorching.

Using a candy thermometer, monitor the pasteurization temperature and maintain it at 150 degrees for 30 minutes to kill off any wild yeasts and bacteria. Hotter temperatures will cook the ingredients and alter the flavors, but cooler temperatures won't properly sanitize them.

While monitoring the the temperature of the pot, begin to clean and sanitize the rest of your equipment. First, wash everything very well with hot water and antibacterial soap.

Then, rinse all of the equipment well with the star-san solution in the bucket, soaking each item. Use the auto-siphon to fill the carboy, and slosh it around until every spot is sterile. Make sure the solution is in contact with every surface for at least three minutes.

Once the carboy is sanitized, you can begin adding juice using your sanitized funnel. Just add about a gallon at this point, so the hot "must" has a heat sink when it's added, and so its sugars will become more dilute.

Now, add 1 tablespoon of Malic Acid to the heated must- this is to compensate for using store-bought sweet juice rather than fresh cider apples. Malic acid is apple acid, so this will make the cider more tart.

Once the heated must has undergone 30 minutes of pasteurization, ladle it into the prepared carboy

Once all of the heated must is added to the carboy, add the remaining apple juice, until you reach nearly to the neck of the carboy.

Next, dry pitch the yeast into the carboy and funnel, and top off the carboy, making sure to rinse the yeast in the funnel into the carboy. Leave at least three inches of headspace in the carboy to allow for some foaming during the fermentation.

This completes the first phase of this honey-ginger cider recipe; now, we'll use the auto-siphon to draw off a small volume of must for analysis

The initial gravity reads 1.064, which gives us a potential ABV of about 8%. I expect that it will ferment out a bit lower, maybe 7%, due to suspended solids present in the honey.

Finally, seal the carboy with a sanitized bung, and set an airlock filled with 90 grain alcohol firmly into the center of it. We don't want any wild nasties to wind up in the mix.

This is what the final brew looks like now that it's set down. The ginger seems to have settled, and the yeast is in uniform suspension. I hope to update this thread in 24 hours with photos of lovely little bubbles.

UPDATE: 24 hours into primary, the yeast is already hard at work: The airlock is bubbling away at a steady clip of 1 CO2 release every 3 seconds. I'll update again when we rack it down for secondary in about 3-4 weeks.

Last edited by a moderator: