BeechtreeBrewery

Member

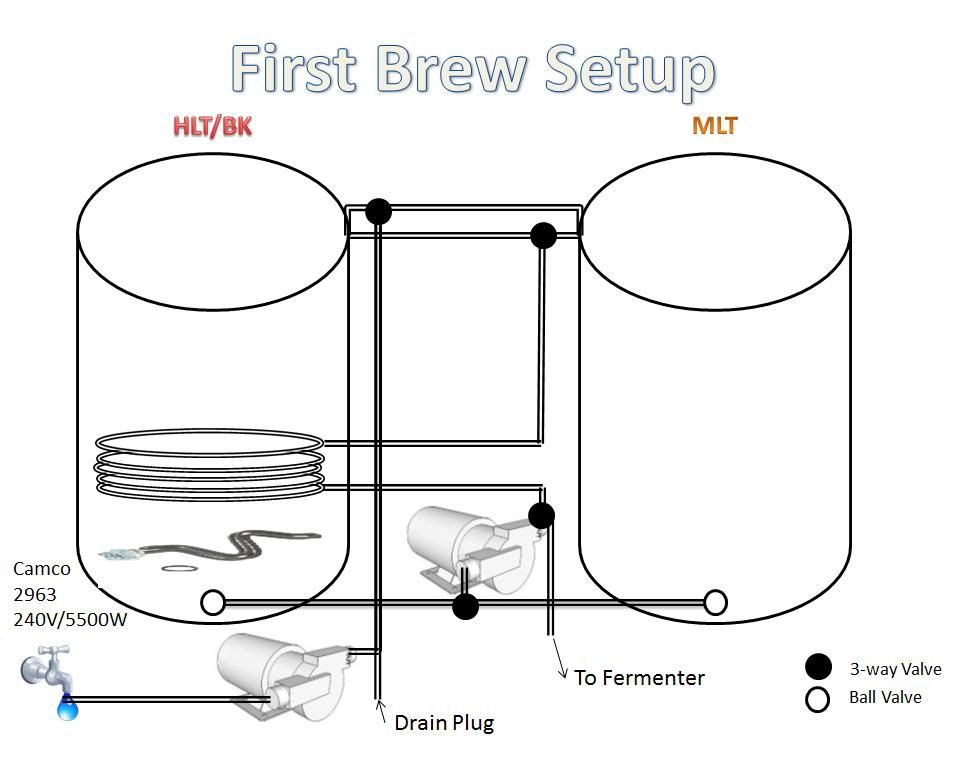

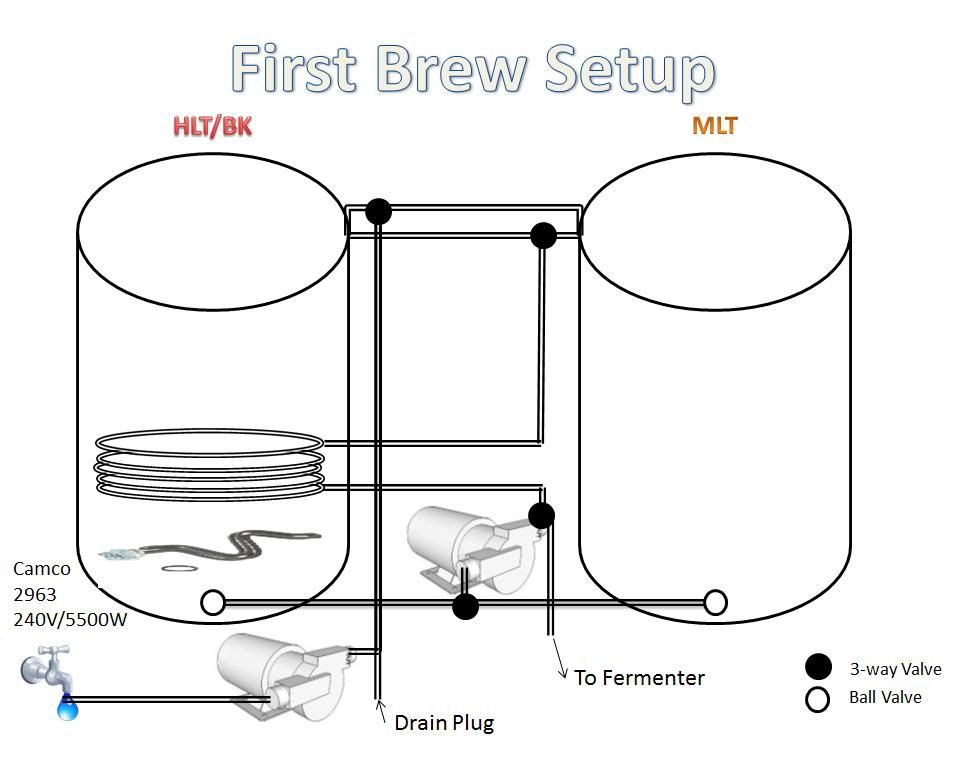

I have been looking to build a single tier system to put in my garage. For that reason I have been focusing on an electric system. I also think it can be pretty efficient. After some research, and trying to keep it as efficient as possible, can a two keggle system match a standard three vessel system.

I am trying to make it pretty simple so I can brew behind my bar while enjoying the time with my friends. I have been brewing with a simple pot on the oven system for a few batches and I am looking to start building my system. Just finishing up the bar now, so I am hoping to get it done before this summer. Any help from the highly experienced brewers here would be helpful.

I am looking to possibly automate it completely... except the grain and hops dumps. Not sure how possible that is, but we will see right? I think the automation will be a work in progress, but if possible i would like to purchase equipment now that will work with the automation later.

Does this seem like it will work out or am I completely missing something?

I am trying to make it pretty simple so I can brew behind my bar while enjoying the time with my friends. I have been brewing with a simple pot on the oven system for a few batches and I am looking to start building my system. Just finishing up the bar now, so I am hoping to get it done before this summer. Any help from the highly experienced brewers here would be helpful.

I am looking to possibly automate it completely... except the grain and hops dumps. Not sure how possible that is, but we will see right? I think the automation will be a work in progress, but if possible i would like to purchase equipment now that will work with the automation later.

Does this seem like it will work out or am I completely missing something?