dinnerstick

Well-Known Member

Does anybody know what the size and pitch of the center rod is on the 20L.

does pitch refer to thread? by size do you mean length? happy to help but a bit lost

Does anybody know what the size and pitch of the center rod is on the 20L.

Has anyone made an extension cord for their Braumeister that connects to a standard US dryer outlet (220 i think?). Most of the posts I have seen people are installing new receptacles or have modified the standard Braumeister cord. I have modified my Braumeister cord but it is short.

Could I buy this cord and rewire it with a dryer plug?

http://www.stayonline.com/detail.aspx?id=8951

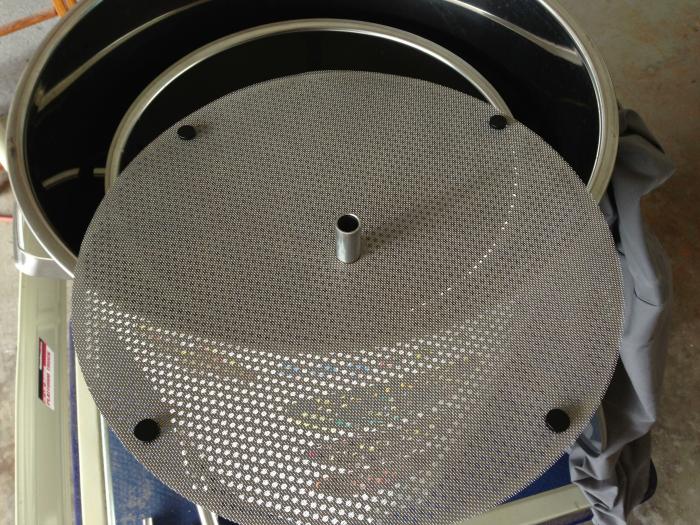

You can also modify the 50l malt pipe as I did to brew smaller high gravity batches.

look up what Batfink did in an earlier post (#1631 pg 164). I have brewed 6 gallon double IPA's using his modification, and can plug the holes with stainless bolts if i ever want to brew a larger batch. I used a Greenlee 1/2" hole punch to pop the holes in the tube. For a 16lb grain bill, I had to use 9 gallons of water, lost 2.5 gallons to absorption and boiloff, and 1/2 gallon to trub. Not sure how this will work with lower gravity beers, might want to get the smaller malt tube if you're going to brew those.

I had a strange event occur during brewing the other day with the Braumeister. During the mash, single infusion at 67C, the BM went into a pump rest at about 50 minutes in. When the pump break was over, the temperature showed 69 degrees, then rapidly increased to 102 degrees, shutting off the pump and heater. Measuring the mash, the temperature was actually 67 degrees.

I was unable to get the mash to finish, so I drained the malt pipe. I completely reprogrammed the BM, setting all mash phases to zero minutes. The BM went to the boiling part of the program, showed the correct temperatures, and finished the boil without incident.

Has anyone else had a similar problem? What could cause this behavior? Bad temp probe? Computer glitch? Bad connection?

Any help would be appreciated.

i would email speidel straight away. their customer service is very good.

Yesterday I attempted my first batch with a new 20l Braumeister and it was the longest brew day that I have ever endured. I started heating my water at 4pm and did not finish the boil until 1:30 am. I have looked through the forum several times and have never seen anyone discuss the issues I encountered.

1. It took almost two hours for the system to heat my strike water to 66 celsius. Is that normal? I filled the Braumeister with warm water from the tap and my house temperature was 72 Fahrenheit.

After I doughed in the Braumeister executed the two mash programs without any observable issues. I drained the grains without sparging and then had to wait oven 90 min for the system to start the boil.

2. The system never reached the programmed 102 celsius for the boil. The hottest temp reached was 98 celsius. I did not use the copper dome or insulating jacket. I had programmed a 90 min boil but it took much longer than that (over 2 hours). I don't have exact times and data because I was several drinks into the brew day/night, but my experience with the Braumeister doesn't seem right.

Is my new system a lemon?

Are you running it on 110V? If you are then you would be cutting the wattage in half.

I figured out the issue. I tested the power cord with a multimeter and it's only pulling 120 volts.....

Hey BM'ers,

I am moving from a 3v HERMS to a 50L BM and the first brew in the BM will be a 23L batch.

I'm thinking that I could mash with the full volume of water, Beersmith is estimating 37 litres (9.7 gallons) of water (using BM profiles obtained from this great thread), the grain bill will be around 4Kg (9lb), then at mash out and after lifting the pipe I could run a recirculating sparge from the spigot over the malt pipe for say 15-20 mins to get a little bit more efficiency (I'll use a separate pump for this).

Has anyone used this method in the 50L BM? Are there any issues to running the full volume for the mash?

EDIT: I've just taken delivery of the BM and made a test run with water and the shortened malt pipe, I can fill with 40L and the level outside the pipe reaches to the uppermost hoist bars, this is probably the maximum amount I could comfortably use. Once the pipe is lifted, the bottom of the pipe is clear of the wort which would allow for an easy sparge. I've adjusted beersmith with a BIAB mash profile which tells me to mash with 32 litres of water for 22 litres in the fermenter (4KG grain bill), I think this is what I'll try.

Roll on Saturday.

Cheers,

Tim.

I might be misunderstanding this, but isn't the BM essentially sparging during the entire mash duration as it is circulating the wort through the grains? Wouldn't an additional recirculating sparge through spigot with a pump as described just accomplish the same thing (except lack of temperature control)? I understand that the lifted grains are saturated with wort so I see the benefit of sparging with heated water (at a water volume near what the grains have absorbed) in an effort to 'drain' the grains of as much sugar as possible + increase efficiency. This may reduce the pre boil OG slightly but can be easily compensated for by slight adjustment of the boil duration to evaporate the excess water and hit target OG.

I'm a fairly new brewer so may have gotten this wrong...

Okay Braumeister brewers, I need your help. But first I'd like to ask people to refrain from telling me not to filter. I would encourage people that DO filter to share their thoughts.

Enter your email address to join: