Hey guys,

Another post about a new system! This is what I am planning for my next project. I have never set one of these up, but have done a lot of trolling on here!

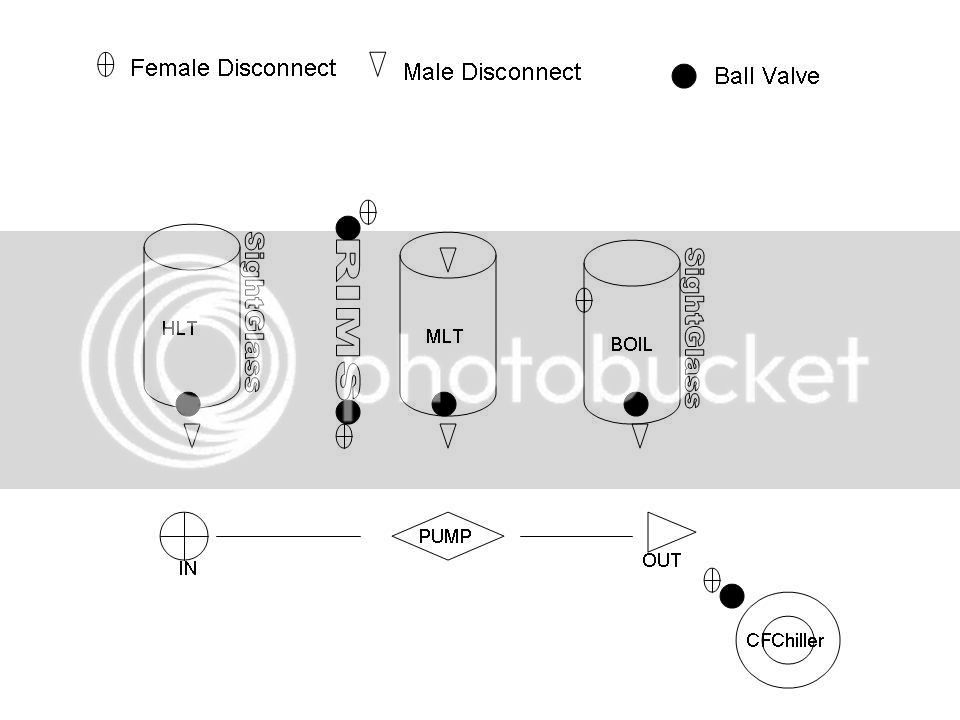

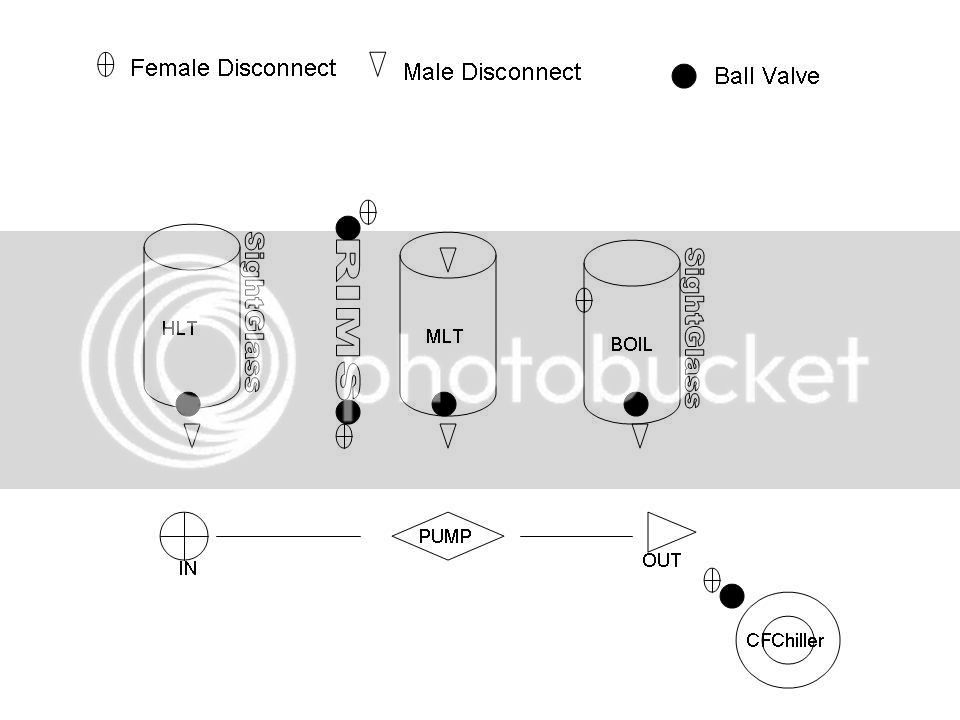

So, the first slide is the plubming. A combination of ball valves and disconnects. I like the idea of one pump and two hoses. Any issues with this?

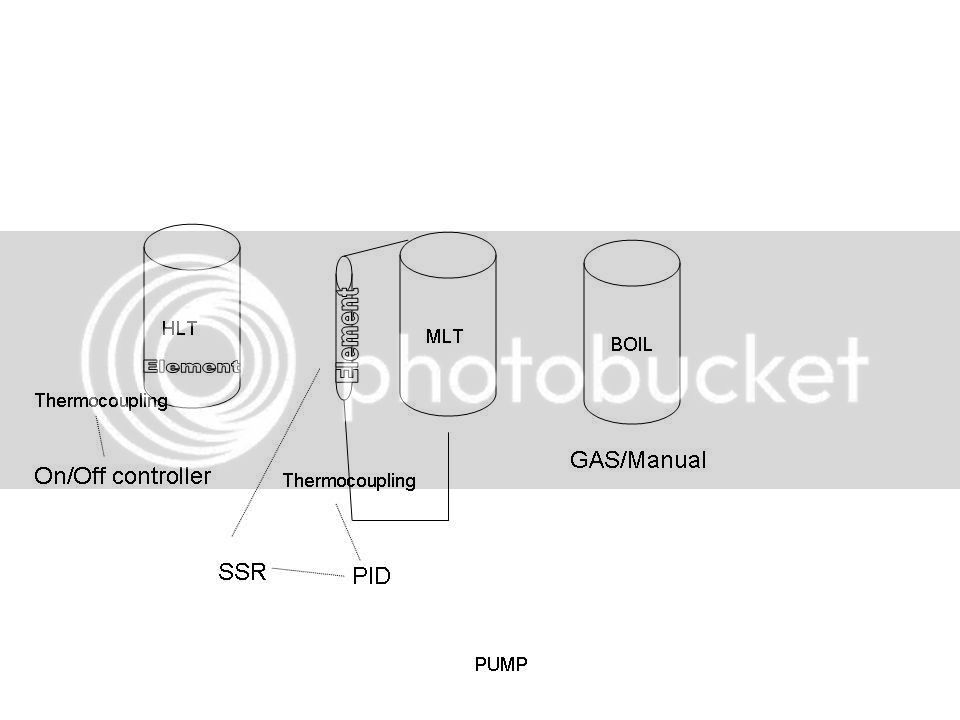

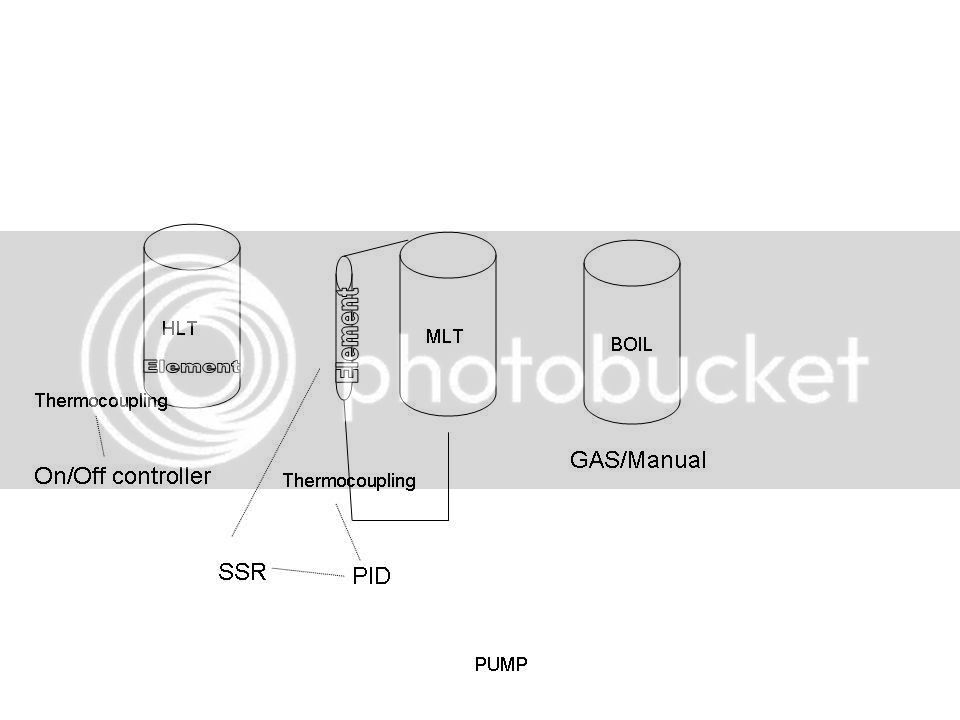

And here is where it gets hairy for me. The electrical part.. Does this look right. Two seperate elements. One controlled by a PID, the other by an on/off. Figure i will add the water a little cooler than strike temp, and let the PID finish it off.

Another post about a new system! This is what I am planning for my next project. I have never set one of these up, but have done a lot of trolling on here!

So, the first slide is the plubming. A combination of ball valves and disconnects. I like the idea of one pump and two hoses. Any issues with this?

And here is where it gets hairy for me. The electrical part.. Does this look right. Two seperate elements. One controlled by a PID, the other by an on/off. Figure i will add the water a little cooler than strike temp, and let the PID finish it off.