I'm in the planning stages for converting my brew system to electric. I'll be putting in a RIMS system, as well as electric heating elements for my HLT and BK. Ideally, I'll use a single control panel to control them all.

I based my design on Kal's tutorial, with the following changes:

I'll be running off a single 30A 240V (10 gauge) wire. In order to run two heating elements at once (for the HLT and RIMS) I'd like to follow the advice given in https://www.homebrewtalk.com/f170/question-about-amp-draw-243248/ where he eventually decided that he could power a 3500W heating element for the HLT and a 2000W element for the RIMS simultaneously, with a 5000W element for the BK.

With respect to functionality, I'd like one switch that will switch between the HLT and BK, as per Kal's design. However, if the switch has the power to the HLT turned on, I'll use the HLT and RIMS switches to turn the individual elements on as needed. Additionally, I'd like the RIMS power switch to be a DPST that will turn on both the pump and the heating element simultaneously, as in the wiring diagram shown below.

I've attached a couple of mock-ups I did to give me a general look/feel of the control panel as a whole. I think the spacing will work out alright, but I'd appreciate anyone's input. The way I picture it working is to use the HLT/BK switch to determine whether power goes to the BK (solely) or to the HLT and/or RIMS. If it goes to the HLT/RIMS, I can use the associated switches to turn each on or off, as needed. This will let me heat sparge water to the desired temp while maintaining my mash temp.

Additionally, I need to come up with a wiring diagram. It's relatively close to Kal's setup, but the lack of timer and an additional RIMS controller are enough to make me want to have a clear understanding of how it should all wire up. Does anyone know what software is used to create the wiring diagrams I've seen online?

Any comments/feedback would be welcome!

Control Panel Mock-Up

Mock-Up with rough dimensions. (Relatively close to scale)

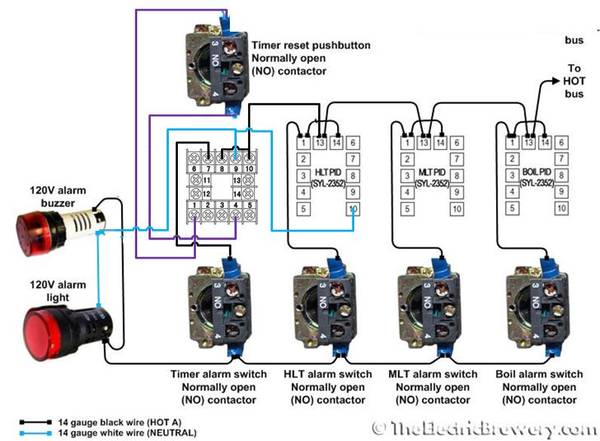

Wiring diagram using DPST switch to use one switch to turn on both the RIMS pump and heating element simultaneously (Found in https://www.homebrewtalk.com/f51/rims-dummies-114997/index86.html#post3159711)

I based my design on Kal's tutorial, with the following changes:

- I'd like to use a 12x16 box, rather than 16x16, if possible. This will allow me to build the control pane into my existing brewing rig.

- In an effort to reduce cost, I won't have a timer, although my mock-up leaves room for one in case I decide to add one later

- I want to control my MT RIMS and HLT heating elements simultaneously, and the BK heating element on its own.

- My system is a 3-tier system, so I won't need to control extra pumps, aside from the pump for the RIMS system. Ideally, when I turn on the RIMS power, it will turn on both the pump and heating element, reducing the number of switches needed. (See explanation below)

I'll be running off a single 30A 240V (10 gauge) wire. In order to run two heating elements at once (for the HLT and RIMS) I'd like to follow the advice given in https://www.homebrewtalk.com/f170/question-about-amp-draw-243248/ where he eventually decided that he could power a 3500W heating element for the HLT and a 2000W element for the RIMS simultaneously, with a 5000W element for the BK.

With respect to functionality, I'd like one switch that will switch between the HLT and BK, as per Kal's design. However, if the switch has the power to the HLT turned on, I'll use the HLT and RIMS switches to turn the individual elements on as needed. Additionally, I'd like the RIMS power switch to be a DPST that will turn on both the pump and the heating element simultaneously, as in the wiring diagram shown below.

I've attached a couple of mock-ups I did to give me a general look/feel of the control panel as a whole. I think the spacing will work out alright, but I'd appreciate anyone's input. The way I picture it working is to use the HLT/BK switch to determine whether power goes to the BK (solely) or to the HLT and/or RIMS. If it goes to the HLT/RIMS, I can use the associated switches to turn each on or off, as needed. This will let me heat sparge water to the desired temp while maintaining my mash temp.

Additionally, I need to come up with a wiring diagram. It's relatively close to Kal's setup, but the lack of timer and an additional RIMS controller are enough to make me want to have a clear understanding of how it should all wire up. Does anyone know what software is used to create the wiring diagrams I've seen online?

Any comments/feedback would be welcome!

Control Panel Mock-Up

Mock-Up with rough dimensions. (Relatively close to scale)

Wiring diagram using DPST switch to use one switch to turn on both the RIMS pump and heating element simultaneously (Found in https://www.homebrewtalk.com/f51/rims-dummies-114997/index86.html#post3159711)