Been reading and searching about fly sparging and concerned I have been doing a correct technique. Been sparging at correct temps. When i Am done with the mash I heat my water and sparge enough water to keep it about one inch above the bed allowing about enough flow to sparge for about one hour. Doing ten gallon batches in keggles, and using a march pump for flow, how does everyone else fly ?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Who fly sparges ? What's your technique ?

- Thread starter Jamming

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

texasbrewer73

Well-Known Member

What exactly is your concern? Is your efficiency low? Are you extracting tannins from grain (too hot or too long a sparge)? Your technique sounds fine - its what I do except that I heat my sparge water before my mash is done.

phoenixs4r

Well-Known Member

- Joined

- Jun 16, 2011

- Messages

- 1,566

- Reaction score

- 93

I am thinking of trying fly sparging to help efficiency with my 5 gallon batches. My 10 gallon batches push 90% so I'm not really worried, but considering i can't seem to pump my mash from the tun to the kettle without going, stupidly, painfully slow, I figured I'd just fly sparge since it's at about that flow rate I can actually pump it.

Brew-boy

Well-Known Member

The way I do it it gravity feed from HLT to pump, pump it to mash tun where I have a manifold on top of the cooler where it drop the water onto the grain bed. From there I gravity feed out and into my kettle.

I go back and forth between batch sparging and continuous sparging, depending on if I'm in a hurry and what's going on that day.

I have a HERMS so I ramp up to mash out temps and then just switch the hoses to sparge and drain the MLT. I have two pumps, so it's a single tier. I keep the same level of liquid above the grainbed that I did during the mash and just continue until I reach my boil volume. It takes me about an hour for a 10 gallon batch, more or less.

I have a HERMS so I ramp up to mash out temps and then just switch the hoses to sparge and drain the MLT. I have two pumps, so it's a single tier. I keep the same level of liquid above the grainbed that I did during the mash and just continue until I reach my boil volume. It takes me about an hour for a 10 gallon batch, more or less.

Northcalais40

Well-Known Member

I use only gravity. Mash in a cooler, so I heat sparge water as soon as I mash in. I heat 7 gal sparge water to 175f, wrap it in astro foil (reflectix) and put on the top shelf (dangerous if you aren't able to lift comfortably). I put my kettle on the floor, my MLT on the short table (purpose built of 2x4's) and attach the drip ring (pex + 3 brass T's).

Then I vorlauf, slow the mlt drain as slow as possible, crank open the drip ring (to get out bubbles) then slow it down as slow as possible.

Sounds complicated but all told the above process takes 2-3 minutes, not including heating. The sparge takes 45 minutes. I go and check the flow every 5 minutes at first to make sure I don't run dry or over flow, then it pretty much goes by itself. I collect 6.5 gallons for a 5 gal batch or 11 gal for a ten gal batch. I have a homemade graduated mash paddle to measure volume.

Then I vorlauf, slow the mlt drain as slow as possible, crank open the drip ring (to get out bubbles) then slow it down as slow as possible.

Sounds complicated but all told the above process takes 2-3 minutes, not including heating. The sparge takes 45 minutes. I go and check the flow every 5 minutes at first to make sure I don't run dry or over flow, then it pretty much goes by itself. I collect 6.5 gallons for a 5 gal batch or 11 gal for a ten gal batch. I have a homemade graduated mash paddle to measure volume.

Jamming

Well-Known Member

What exactly is your concern? Is your efficiency low? Are you extracting tannins from grain (too hot or too long a sparge)? Your technique sounds fine - its what I do except that I heat my sparge water before my mash is done.

Efficiency is not really my concern because i always seem to hit my OG, what i was wondering is what people use as a sparge arm and there exact technique. The only concern i have is temps and technique. I am totally self taught from this forum and a few tips at my local brew store.

I normally sparge at about 175f for a basic american ale, I start my water and begin sparging slowly and at the same time i slowly drain the wort, Never return any of it back to the grain bed, do people dump some wort back in the grains before sparging ? And how much Wort do i drain off the grain before sparging. Or should i add water before draining any Wort.

Jamming

Well-Known Member

I use only gravity. Mash in a cooler, so I heat sparge water as soon as I mash in. I heat 7 gal sparge water to 175f, wrap it in astro foil (reflectix) and put on the top shelf (dangerous if you aren't able to lift comfortably). I put my kettle on the floor, my MLT on the short table (purpose built of 2x4's) and attach the drip ring (pex + 3 brass T's).

Then I vorlauf, slow the mlt drain as slow as possible, crank open the drip ring (to get out bubbles) then slow it down as slow as possible.

Sounds complicated but all told the above process takes 2-3 minutes, not including heating. The sparge takes 45 minutes. I go and check the flow every 5 minutes at first to make sure I don't run dry or over flow, then it pretty much goes by itself. I collect 6.5 gallons for a 5 gal batch or 11 gal for a ten gal batch. I have a homemade graduated mash paddle to measure volume.

OK this helps me, vorlauf is dumping the wort back into the grains ? Of course gently to avoid stirring up the grains, Why do you do this ?

Jamming

Well-Known Member

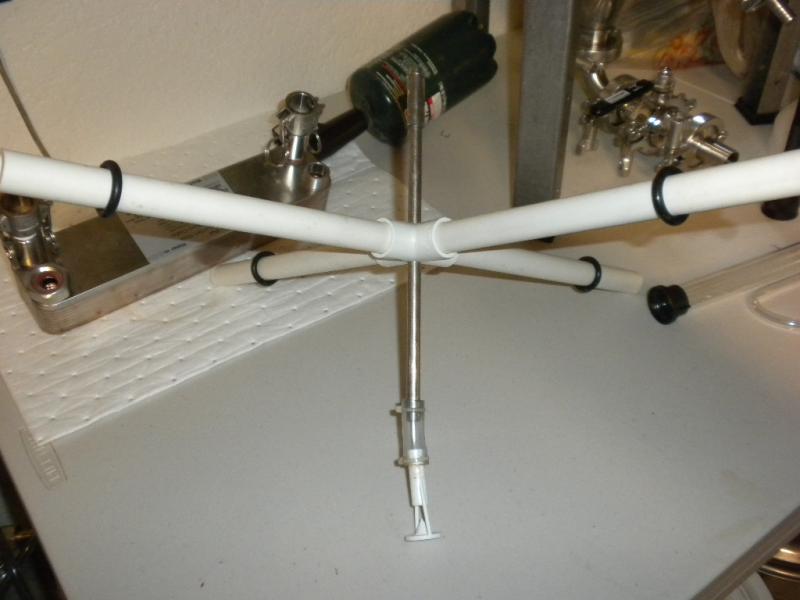

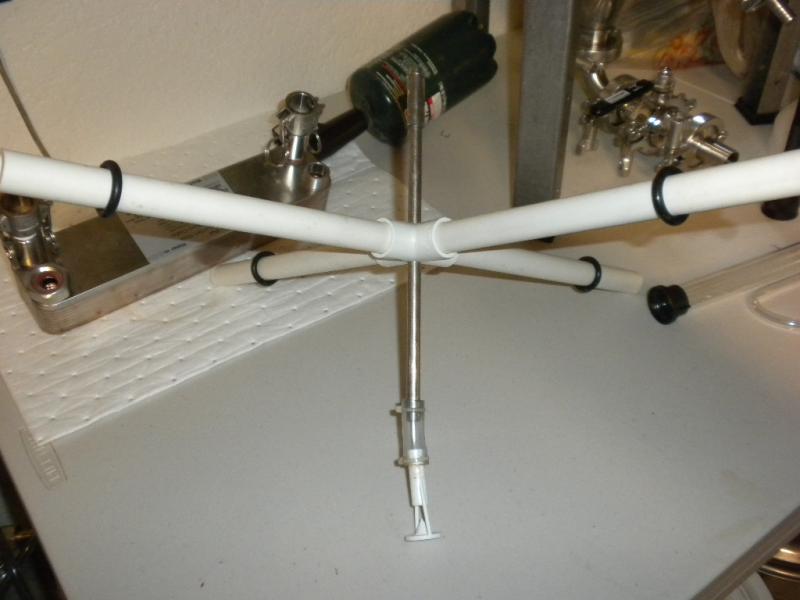

This is what i have been using, I would like to build or buy something that spreads the water evenly across the grain bed, any ideas on a sparge arm build would be greatly appreciated. I often have to move the arm around to prevent channeling, Pain in the butt.

Northcalais40

Well-Known Member

To vorlauf is to very slowly begin to drain your MLT so that the grain bed "sets" and filters out fine grist particles. You can see the runnings go from cloudy to bright in 1-2 qts. It reduces the amount of grist and therefore trub and astringency in the wort.

Many will disagree. But this is the traditional rationale.

Many will disagree. But this is the traditional rationale.

wailingguitar

Well-Known Member

I go back and forth between batch sparging and continuous sparging, depending on if I'm in a hurry and what's going on that day.

I have a HERMS so I ramp up to mash out temps and then just switch the hoses to sparge and drain the MLT. I have two pumps, so it's a single tier. I keep the same level of liquid above the grainbed that I did during the mash and just continue until I reach my boil volume. It takes me about an hour for a 10 gallon batch, more or less.

Thank you, Yooper, for saying continuous sparging! I loathe the term "fly sparge"! LOL

OP; I do a variation on a continuous sparge. Instead of taking the entire hour to slowly run sparge water in, after mashing I begin runoff then get all my sparge water in in about 5-10 minutes. The trick is a) having a MLT large enough to hold it all and b) to do it without disturbing the top of the grain bed significantly. Basically, it isn't necessary to match in and out flow as long as your run off time is the same (about an hour) and the water isn't actually mixing in with the mash, but staying above it until gravity drains it through. Now, this does assume you have an insulated MLT so you don't lose heat.

SavoryChef

Well-Known Member

I have a two tier system, so i gravity feed my sparge water using a 5 foot silicon hose coiled on top of the grain bed. Works like a charm.

Jamming

Well-Known Member

To vorlauf is to very slowly begin to drain your MLT so that the grain bed "sets" and filters out fine grist particles. You can see the runnings go from cloudy to bright in 1-2 qts. It reduces the amount of grist and therefore trub and astringency in the wort.

Many will disagree. But this is the traditional rationale.

Interesting, because I filter my wort as I pump it from the mash tun through a painters filter bag into my boil keggles. Is there any advantage to putting it back into the tun.

Jamming

Well-Known Member

I have a two tier system, so i gravity feed my sparge water using a 5 foot silicon hose coiled on top of the grain bed. Works like a charm.

Pics ? Are there holes in the hose and a plugged end.

SavoryChef

Well-Known Member

I dont have pics. There are no holes in the tubing. Theelectricbrewery.com does the same thing as well as the blinchman auto sparge. Check them out, they have pics.

tdbc2011

Well-Known Member

I will try fly sparging this weekend. So do I start the process before the mash is drained or as soon as I start draining the mash.

wailingguitar

Well-Known Member

I will try fly sparging this weekend. So do I start the process before the mash is drained or as soon as I start draining the mash.

Either just before or right after. The effect will be the same. Generally, you would start your runoff then turn the sparge on. This is because there is the assumption that you would be doing a vorlauf and as soon as you see wort clarity that satisfies you it would be diverted to the kettle and then the sparge would start.

Tubbster85

Well-Known Member

While your fly sparging, do you continuously sparge until you have your pre boil volume even if you still have mash/water(i dont know if its considered wort at this point)in the mash tun or do you want to get all of the water in the mash tun out at your pre boil volume?

texasbrewer73

Well-Known Member

I generally sparge until my BK is full. Unless it's a small beer and the gravity falls below 1.007-8 when lautering.

FredTheNuke

Well-Known Member

This is what i have been using, I would like to build or buy something that spreads the water evenly across the grain bed, any ideas on a sparge arm build would be greatly appreciated. I often have to move the arm around to prevent channeling, Pain in the butt.

http://www.loc-line.com/half-inch.php

Use the 1/2" Circle Flow Kit from Loc Line. Works awesome as a sparge assembly and is fully adjustable, easy to clean, etc! My rotating sparge arm clogged up doing HERMS through it - with the Loc Line all the goooey pre-wort flows just fine.

FredTheNuke

Well-Known Member

here is a Youtube video of the Loc Line Sparge Assembly.

http://www.google.com/url?sa=t&rct=...hdSoAw&usg=AFQjCNEebgYhEp7ynTe2fe_hFdybLMwnTw

http://www.google.com/url?sa=t&rct=...hdSoAw&usg=AFQjCNEebgYhEp7ynTe2fe_hFdybLMwnTw

CKing

Well-Known Member

http://www.homebrewstuff.com/sparge-manifold-5-gal-igloo.html

^ That's what I use. It's connected to the mash tun lid and is fed from another 5-gallon beverage cooler HLT. Nice and easy with great results.

^ That's what I use. It's connected to the mash tun lid and is fed from another 5-gallon beverage cooler HLT. Nice and easy with great results.

tdbc2011

Well-Known Member

Either just before or right after. The effect will be the same. Generally, you would start your runoff then turn the sparge on. This is because there is the assumption that you would be doing a vorlauf and as soon as you see wort clarity that satisfies you it would be diverted to the kettle and then the sparge would start.

Thanks for the help.

SnidelyWhiplash

Well-Known Member

Pics ? Are there holes in the hose and a plugged end.

put a hose clamp on the end to close it, cut holes spread over the last foot, coil that in a circle halfway between the middle and the walls, with the holes facing up.

keeping it off the edge and closing the end are important to avoid channeling.

Jamming

Well-Known Member

http://www.loc-line.com/half-inch.php

Use the 1/2" Circle Flow Kit from Loc Line. Works awesome as a sparge assembly and is fully adjustable, easy to clean, etc! My rotating sparge arm clogged up doing HERMS through it - with the Loc Line all the goooey pre-wort flows just fine.

These are great ! Thanks for the video and link, It appears in the video that the sparge is missing the outer area of the mash, Is this any problem. I normally keep my sparge water about 1-2 iches above the grain bed for less channeling, You system looks great, Will give it a try. I like the way it can be taken apart and cleaned.

FredTheNuke

Well-Known Member

If you Continuous Sparge and keep 1-2 inches above the grain bed then it will not matter. The Loc Line will simplly apply that water without digging into the grain bed. YOu can also twist the Loc Line discharges so every other one points outward and you will get almost out to the edge (and more gently apply the water).

OP; I do a variation on a continuous sparge. Instead of taking the entire hour to slowly run sparge water in, after mashing I begin runoff then get all my sparge water in in about 5-10 minutes. The trick is a) having a MLT large enough to hold it all and b) to do it without disturbing the top of the grain bed significantly. Basically, it isn't necessary to match in and out flow as long as your run off time is the same (about an hour) and the water isn't actually mixing in with the mash, but staying above it until gravity drains it through. Now, this does assume you have an insulated MLT so you don't lose heat.

I've been batch sparging but thinking about trying continuous sparging. Your technique sounds interesting, but one thing worries me. What happens if you get a stuck mash? If you only have an inch or two above the grain, you can stir, vorlauf again, and start over, but if this happens with all the sparge water in the tun and you have to stir to clear it, then it seems you're forced into doing a batch, or maybe it could even be considered a no-sparge, with corresponding loss of efficiency, causing you to undershoot your gravity.

Similar threads

- Replies

- 30

- Views

- 3K

- Replies

- 13

- Views

- 2K

- Replies

- 14

- Views

- 1K

- Replies

- 14

- Views

- 1K

- Replies

- 7

- Views

- 2K