You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your sculpture or brew rig

- Thread starter Onescalerguy

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Here's my wire rack shelving, 3-vessle, AG setup with one pump.

Note: I plan to add metal shielding around the burner and hose-clamp to support the joints near the burner as a safety measure.

Here's the full post...

Note: I plan to add metal shielding around the burner and hose-clamp to support the joints near the burner as a safety measure.

Here's the full post...

BareKnuckleBrew

Active Member

- Joined

- Apr 29, 2012

- Messages

- 29

- Reaction score

- 10

Always upgrading!!!

gr8abe

Member

Here's 'Qbert' pump and gravity fed. Electric mash and propane boil/ hlt.

BeardedBrews

Well-Known Member

That's a monster CFC. Who makes that one?

Also, that device in the front looks like it might convert gases to liquids to be used for vehicle fuel (or something like that) [emoji16]

Here's 'Qbert' pump and gravity fed. Electric mash and propane boil/ hlt.View attachment 603156View attachment 603157

Love the Bauhaus look.

Trainman28

Active Member

- Joined

- Oct 20, 2016

- Messages

- 27

- Reaction score

- 10

Custom e biabasket. 21.5 gal stout tank w 240V connection & tangical whirlpool. Arbor fab basket, riptide pump, ss recirculation manifold, and auber cube controller. I finally got to do my first brew on it last week and I'm impressed. Can't wait to dial it in. 75% BH efficiency on first try

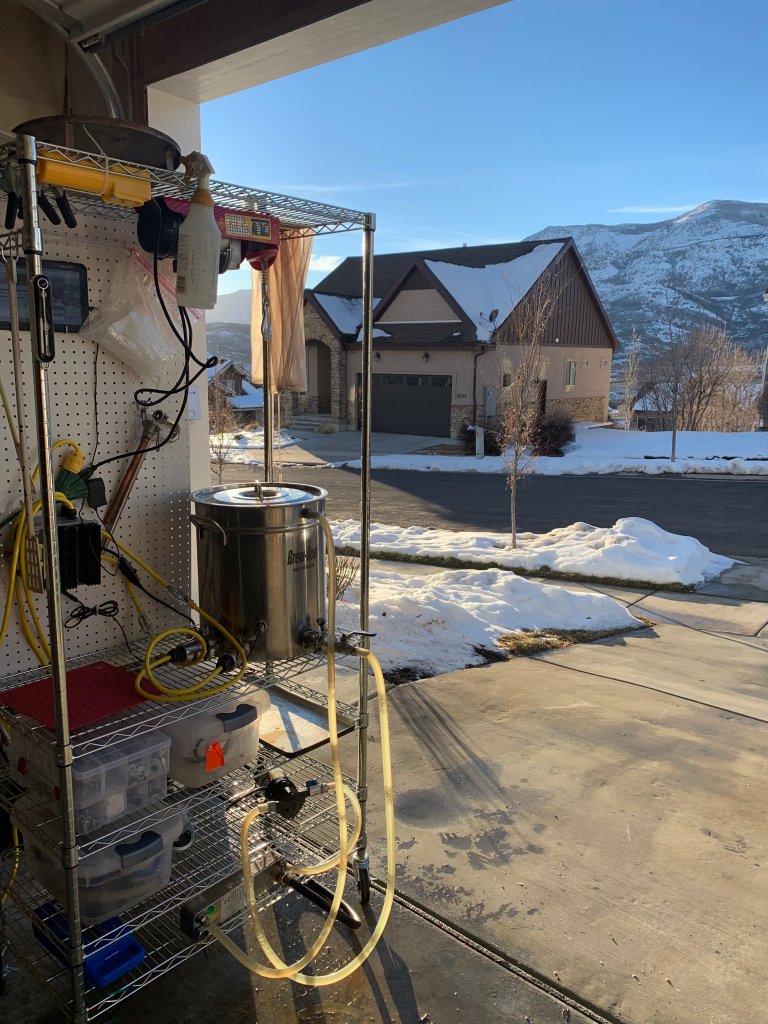

My single vessel built with BrewManiacEx controller. Still have some adjustments but for now it delivers what I need.

View attachment 599697

Very neat. Please tell me more about your rig !

It is a bigger version of the Grainfather ? BIAB or do you insert a 2nd vessel inside for the mash tun ? Did you roll the steel for the base ? Is the pump contained in the base or mounted on the outside ?

cnash

Well-Known Member

Need more info as I have a Brew-Boss and am looking towards my stand options. I am planning on building my own, but this looks nice as well if it's well priced and supports the weight .

macphergus

New Member

- Joined

- Apr 7, 2013

- Messages

- 2

- Reaction score

- 4

My fermentation set up

- Joined

- Jul 12, 2017

- Messages

- 485

- Reaction score

- 416

Looks like a livestock water tank for an exaughst hood. How well does that work without dripping and does the rolled edge catch water and then drains off out of picture? What type of fan/fans are you using? Evey thing home made I've done eventually drips, and not a huge fan of drippings in my kettle. Thanks in advance!

HiImBrian

Well-Known Member

- Joined

- Aug 15, 2014

- Messages

- 273

- Reaction score

- 67

My fermentation set up

Neat idea, but I'm curious as to why you didn't just use a vertical freezer.

Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

I found the key is good airflow. I use a similar setup that would typically allow dripping back but with a 600cfm exhaust (I think) there's zero condensation buildup in the hood. I also have a larger than most kettle with a higher than typical boiloff rate. CheersLooks like a livestock water tank for an exaughst hood. How well does that work without dripping and does the rolled edge catch water and then drains off out of picture? What type of fan/fans are you using? Evey thing home made I've done eventually drips, and not a huge fan of drippings in my kettle. Thanks in advance!

NOW, this is a real MAN CAVE!

And it's all stored in a shed out back.

-TC

Need more info as I have a Brew-Boss and am looking towards my stand options. I am planning on building my own, but this looks nice as well if it's well priced and supports the weight .

The rack and pegboard were both purchased at home depot for about $100. I bought the winch off of Amazon, it was the least expensive one I could find.

Rack:

https://www.homedepot.com/p/TRINITY...ack-with-Wheels-in-Chrome-TBFZ-0906/203619535

frozengator

Well-Known Member

- Joined

- Dec 2, 2014

- Messages

- 164

- Reaction score

- 34

Picture after mashing out

awoitte

Well-Known Member

- Joined

- May 9, 2017

- Messages

- 184

- Reaction score

- 21

I like your sink.. Am thinking about adding one to my brew house (garage). Aside from being able to get suds on things and rinse, are you able to get a little gunk in it as well, or is it purely for 100% liquid for the drain?

That sink is one my favorite pieces of brewing equipment... Perfect for washing kegs, cleaning carboys, tipping the boil kettle (on the right in the photo) on its side for easy spray cleaning... it's awesome.I like your sink.. Am thinking about adding one to my brew house (garage). Aside from being able to get suds on things and rinse, are you able to get a little gunk in it as well, or is it purely for 100% liquid for the drain?

And yes, it can handle "gunk." I dump spent hops into the sink and stir them like soup until they drain. Even a super-hoppy beer like my hopslam clone (over a pound of hops in the boil) will drain. I did install a Studor valve on the drain pipe (you can see the white vertical pipe with the valve on top on the right side of the sink) to allow the drain to flow faster.

Happy brewing!

www.pinegrovebrewworks.com

Scarabrew

Well-Known Member

It's a single vessel with wort recirculation just like Grainfather. Inside the keggle there is this basket used for filtering.Very neat. Please tell me more about your rig !

It is a bigger version of the Grainfather? BIAB or do you insert a 2nd vessel inside for the mash tun ? Did you roll the steel for the base ? Is the pump contained in the base or mounted on the outside ?

Yes, I have this friend with access to a shop. He rolled the steel sheet to make this base to accomodate the controller and the pump. Everything is controlled through the smartphone.

Scarabrew

Well-Known Member

Tried to "play" a couple of times and then realized it was a screenshot, LOL.Custom e biabasket. 21.5 gal stout tank w 240V connection & tangical whirlpool. Arbor fab basket, riptide pump, ss recirculation manifold, and auber cube controller. I finally got to do my first brew on it last week and I'm impressed. Can't wait to dial it in. 75% BH efficiency on first tryView attachment 603344

In the end you bought the same kettle as Freddy, andrew and Irish brewer did, right? This kettle looks pretty nice. Congrats.

Trainman28

Active Member

- Joined

- Oct 20, 2016

- Messages

- 27

- Reaction score

- 10

Yes. I think it's a little modified from their setup. I believe they went through brew hardware. I got mine directly from stout. I have a domed dish bottom. But I'm pretty sure they are all stout tanks. I love it so far. Went from making good beer with propane and wilser bag to amazing beer with this setup.Tried to "play" a couple of times and then realized it was a screenshot, LOL.

In the end you bought the same kettle as Freddy, andrew and Irish brewer did, right? This kettle looks pretty nice. Congrats.

It's a single vessel with wort recirculation just like Grainfather. Inside the keggle there is this basket used for filtering.

What basket did you use ?

Yes, I have this friend with access to a shop. He rolled the steel sheet to make this base to accomodate the controller and the pump.

Very neat and tidy.

Everything is controlled through the smartphone.

What controller are you using ?

It’s a work in progress. She’ll brew beer now....she’ll just do it better later.

Scarabrew

Well-Known Member

¹ I designed the basket to fit inside the keggle and this friend built it. There is nothing fancy. It's just a basket, solid on sides and laser perforated at the bottom. Something like the Unibräu basket.¹ What basket did you use?

² Very neat and tidy.

³ What controller are you using?

² Thanks.

³ BrewManiacEx is the controller. More info here: https://www.homebrewtalk.com/forum/threads/yabc-yet-a-brew-controller-brewmaniacex.596907/

After I cleared a space in my tool shed, I now have a brewshed!Here's my wire rack shelving, 3-vessle, AG setup with one pump.

Note: I plan to add metal shielding around the burner and hose-clamp to support the joints near the burner as a safety measure.

Here's the full post...

View attachment 599939

I've also made a few important changes to the rig.

1) I raised the mash, kettle and CFC level to waist height. This eases he general operation and allows me to gravity drain the CFC at the end to waste less precious wort.

2) I added a drain valve to the pump. This was huge as it made priming the pump super easy and the side benefit was it virtually eliminated the wort and water drippings.

3) I added a sink. Game changer! Even unplumbed as my shed is unheated and would feaaze pipes. Using a spare cooler with recycled chiller water works great. And dumping the grey water bucket is not a big deal. But being able to clean up everything right away is Yuge!

Last edited:

Meet Thing1, a 5Kw induction all in one.

5 Kw Induction

11 gallon boil kettle

8 gallon grain "basket"

CraftBrewPi controller for induction coil, pump, stir/rake motor and future possible RIMS tube if I add one.

March pump

Custom welded SS frame

I posted in electric brewing because of the induction aspect and it's not really a traditional brewstand per se.

https://www.homebrewtalk.com/forum/threads/meet-thing-1-a-5kw-induction-all-in-one.661665/

5 Kw Induction

11 gallon boil kettle

8 gallon grain "basket"

CraftBrewPi controller for induction coil, pump, stir/rake motor and future possible RIMS tube if I add one.

March pump

Custom welded SS frame

I posted in electric brewing because of the induction aspect and it's not really a traditional brewstand per se.

https://www.homebrewtalk.com/forum/threads/meet-thing-1-a-5kw-induction-all-in-one.661665/

Hello, his is my invention, its called Zeus1 Machine.

It took me 1-1/2 years to study the process, design the machine and build it.

This is the first prototype which saw the light around January 2016.

It uses only 2 tanks to brew and ferment, the bottom one which i call unitank and the upper tank, the grain tank.

It is all made with stainless steel except the hoses of course which are food grade, most of the parts are commercial, except of course the tanks which are custom made and the heating boiler, that one you can see it attached to one of the 3 legs of the grain tank.

The temperature and time controller parts are also commercial, most of them i found them in AmazonUS but it was all designed by me too.

I mixed food grade fittings with industrial fittings depending on the use, food grade for fermenting purposes mainly and industrial for the non critical processes.

In general the two tanks are connected to mash and boil, then unitank (bottom) one is disconnected to cool down and pitch the yeast while the grains are extracted from the conical bottom of the grain tank (upper), then the unitank is pushed with its wheels to a room where its jacked will be connected to cold water to maintain the fermentation temperature.

The unitank can brew up to 100 liters, it has a jacket which is water cooled by a remote water refrigerator like the ones used for small fish tanks, the jacket size is 20 liters and the minimum temperature achieved at fermentation is 7 °C - 6 °C.

One the beer is ready and the unitank is pressurized, the conical bottom and the sampling valve allows me to extract the yeast sludge, the maximum pressure i have allowed it to achieve is 50psi, however i dont recommend to ferment at those high pressures due to a lack of proper flocculation and i have notice an increase in off flavors, anyway, once the fermentation is finished, the unitank allows me to connect a CO2 tank to pressurize it some more, from 10psi after fermenting to 20 or 30psi, so i can bottle the finished beer by connecting a hose to the conical bottom outlet which it also has a sight hose for measure the volume inside the tank.

I hope you like it guys.

If anyone want to know more about it email me to [email protected]

It took me 1-1/2 years to study the process, design the machine and build it.

This is the first prototype which saw the light around January 2016.

It uses only 2 tanks to brew and ferment, the bottom one which i call unitank and the upper tank, the grain tank.

It is all made with stainless steel except the hoses of course which are food grade, most of the parts are commercial, except of course the tanks which are custom made and the heating boiler, that one you can see it attached to one of the 3 legs of the grain tank.

The temperature and time controller parts are also commercial, most of them i found them in AmazonUS but it was all designed by me too.

I mixed food grade fittings with industrial fittings depending on the use, food grade for fermenting purposes mainly and industrial for the non critical processes.

In general the two tanks are connected to mash and boil, then unitank (bottom) one is disconnected to cool down and pitch the yeast while the grains are extracted from the conical bottom of the grain tank (upper), then the unitank is pushed with its wheels to a room where its jacked will be connected to cold water to maintain the fermentation temperature.

The unitank can brew up to 100 liters, it has a jacket which is water cooled by a remote water refrigerator like the ones used for small fish tanks, the jacket size is 20 liters and the minimum temperature achieved at fermentation is 7 °C - 6 °C.

One the beer is ready and the unitank is pressurized, the conical bottom and the sampling valve allows me to extract the yeast sludge, the maximum pressure i have allowed it to achieve is 50psi, however i dont recommend to ferment at those high pressures due to a lack of proper flocculation and i have notice an increase in off flavors, anyway, once the fermentation is finished, the unitank allows me to connect a CO2 tank to pressurize it some more, from 10psi after fermenting to 20 or 30psi, so i can bottle the finished beer by connecting a hose to the conical bottom outlet which it also has a sight hose for measure the volume inside the tank.

I hope you like it guys.

If anyone want to know more about it email me to [email protected]

Attachments

Omarke, nice work though looks dangerously top heavy and tip prone. Hopefully a safety cable ties it off when in use.

How does the aquarium pump hold up to the heat? I have several but didn't think they could tolerate brewing temperatures.

How does the aquarium pump hold up to the heat? I have several but didn't think they could tolerate brewing temperatures.

@omarke uses an aquarium chiller on his fermentor. That is a beer pump that he is using hot-side.Omarke, nice work though looks dangerously top heavy and tip prone. Hopefully a safety cable ties it off when in use.

How does the aquarium pump hold up to the heat? I have several but didn't think they could tolerate brewing temperatures.

hafmpty

Well-Known Member

Hello, his is my invention, its called Zeus1 Machine.

Whatever this thing is...it looks awesome! Do you have any brew day footage? I’d LOVE to see this thing in action. Post it up on Youtube for folks to check out. I really like the originality and engineering that went into this.

scott.howell.9022

Member

- Joined

- Jun 4, 2018

- Messages

- 8

- Reaction score

- 32

scott.howell.9022

Member

- Joined

- Jun 4, 2018

- Messages

- 8

- Reaction score

- 32

my modest lil brewery

scott.howell.9022

Member

- Joined

- Jun 4, 2018

- Messages

- 8

- Reaction score

- 32

- Joined

- Jun 12, 2014

- Messages

- 574

- Reaction score

- 191

Mouth watering.

I also use the EZboil controllers as well as the same insulation wrap

Hemicharger99

Member

Similar threads

- Replies

- 4

- Views

- 762

- Replies

- 2

- Views

- 1K