Tyrant

Member

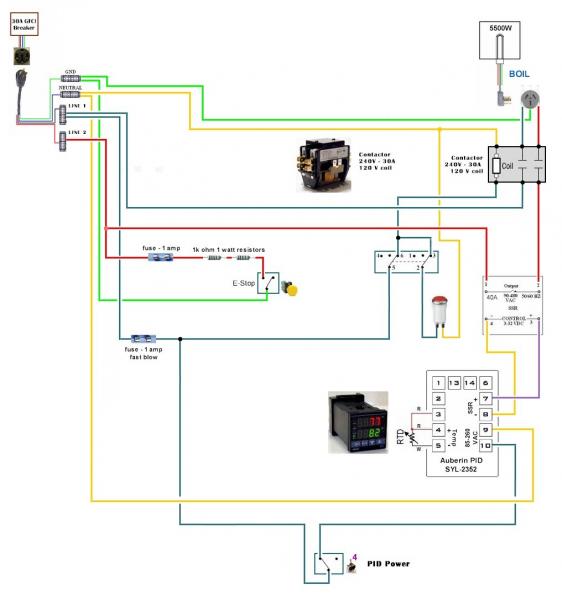

This is my first real post on the forums, but have gather a ton of brewing knowledge from here. So first off, thank you everyone, HBT and PJ for the wiring diagrams.

I have already purchased and put together all my parts for an my ebrew system.

1 pot, maybe 2 eventually to get boil and mash

1 PID, 1 SSR, 1 contactor, 1 estop

I have everything wired up already, with a main switch for the PID, selector switch for the element (eventually going to go with 2 PIDs so I bought for expansion in the future) and a LED indicator light for the element being on.

I have read a bunch on here and know a bit about electrical circuits (not an expert mind you) and would like someone to take a look at my wiring.

I have a neutral going into the left side of the contactor that's T-off into the indicator light. Is this OK practice to T off, or run a separate line from the power block?

For line 1 into the PID power switch, and element switch, I used a line from the power block, to a fuse, then split out to each switch.

For the main lines, power block to SSR, contactor, element and such I used stranded AWG 10 THHN. For the PID power, LED contactor coil I ripped apart a 120v power strip and used those wires. So for anything providing power to the element I used 10 THHN, everything else I used the power strip wire. Will this be OK since I'm not running much into there? I also used this wire for the neutral. Ground is AWG 10 as well.

As of right now, nothing is soldered. Just using tape to keep things together until I confirm the wiring is complete.

I am using the auberins PID box. It has enough room for 1 element, but doesn't seem Ok for 2. Again, just using this for now until I move up to a more permanent solution.

I do have GFCI on this as well. I'm not stupid...

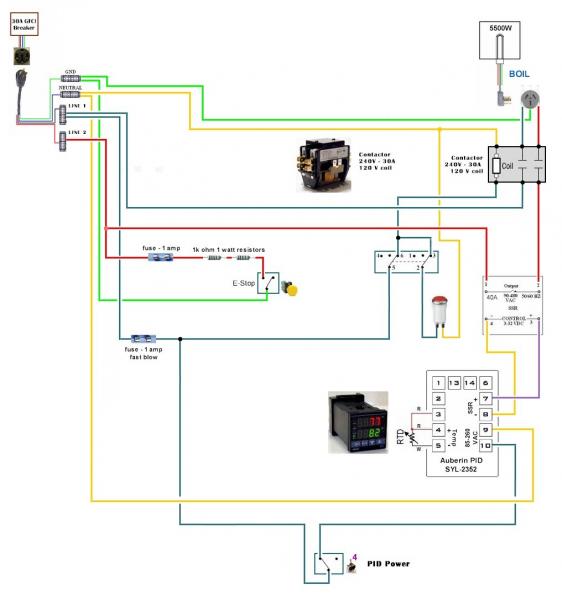

I have already purchased and put together all my parts for an my ebrew system.

1 pot, maybe 2 eventually to get boil and mash

1 PID, 1 SSR, 1 contactor, 1 estop

I have everything wired up already, with a main switch for the PID, selector switch for the element (eventually going to go with 2 PIDs so I bought for expansion in the future) and a LED indicator light for the element being on.

I have read a bunch on here and know a bit about electrical circuits (not an expert mind you) and would like someone to take a look at my wiring.

I have a neutral going into the left side of the contactor that's T-off into the indicator light. Is this OK practice to T off, or run a separate line from the power block?

For line 1 into the PID power switch, and element switch, I used a line from the power block, to a fuse, then split out to each switch.

For the main lines, power block to SSR, contactor, element and such I used stranded AWG 10 THHN. For the PID power, LED contactor coil I ripped apart a 120v power strip and used those wires. So for anything providing power to the element I used 10 THHN, everything else I used the power strip wire. Will this be OK since I'm not running much into there? I also used this wire for the neutral. Ground is AWG 10 as well.

As of right now, nothing is soldered. Just using tape to keep things together until I confirm the wiring is complete.

I am using the auberins PID box. It has enough room for 1 element, but doesn't seem Ok for 2. Again, just using this for now until I move up to a more permanent solution.

I do have GFCI on this as well. I'm not stupid...