Lucky_Chicken

Well-Known Member

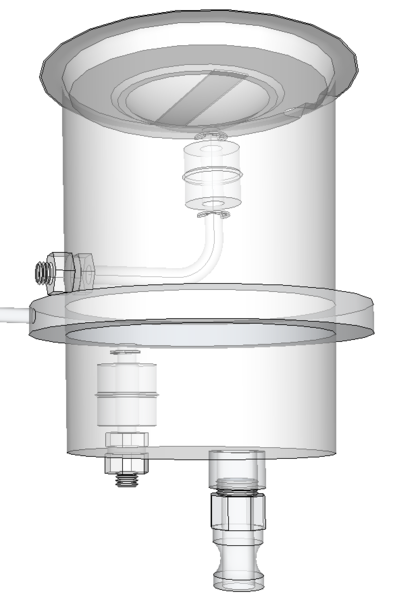

So I was doing some research and investigating for building my all electric system and came across a wort grant and it gave me an idea.

Has anyone ever tried to use a wort grant with a heating element in the grant to maintain mash temperatures? Might not have to be very big maybe 1500W.

Concerns I have:

- Would this interrupt the whirlpool effect?

- Not provide enough heating?

I am guessing you would need some kind of level sensor so the pump doesnt overpower the gravity mash draining and fry the element/ kill the whirlpool.

Has anyone ever tried to use a wort grant with a heating element in the grant to maintain mash temperatures? Might not have to be very big maybe 1500W.

Concerns I have:

- Would this interrupt the whirlpool effect?

- Not provide enough heating?

I am guessing you would need some kind of level sensor so the pump doesnt overpower the gravity mash draining and fry the element/ kill the whirlpool.