Boodlemania

Well-Known Member

"Probe in air" is NOT the way to do it, especially for fermenting beer. It will kill your compressor and also not keep ferm'ing beer temps stable.

You may have your probe too well insulated which prevents the ambient from influencing the probe and causing an early shutoff (hysteresis compensation). You may also have to probe in an area that gets more residual cooling. A small computer fan can help.

Your heater sounds oversized. You only need ~40 watts. Also, why is your heater even plugged in? I know you are probably proud of the job you did wiring it up and all, but it's July!

I have a feeling that the beer temp isn't varying as much as the probe temp, and the low temps at the probe are being warmed by both the beer and the heater heating the air.

All of the above is true.

The "probe in air" is not how I ferment. Just data I took when checking out the chamber performance before actually using it for a fermentation.

I have a 60W infared reptile lamp with fan. Fan kicks on with lamp. No fan for cooling.

Also, by the therm stuck on side of carboy, beer temp isn't flucuating as much as probe temp. Beer temp is about a degree or two F above the setpoint, per the stick-on thermometer.

Options I'm thinking of pursuing:

- Better insulation for probe to more accurately read beer temp.

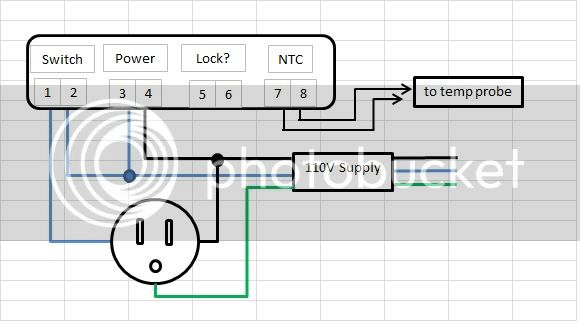

- fan for cooling. This will be a no brainer given the way I wired by chamber.

- widening the deadband on the controller.