I have a few questions for anyone who has tried this fermentation technique:

Will beers, such as a weizen, still taste right when fermented under pressure?

Will the yeast be as sesitive to temp swings as they are when fermented under an airlock? I want to try a lager. Will the dry yeast or liquid yeast work better with this technique?

Wortmonger: Where did you find the cheap back pressure relief valve?

Thanks for the interesting thread!

Don't go cheap on your spunding valve. I told Poindexter what I would buy if doing it all over and his valve is superior to what I use.

Here is post #39 in this thread about what I recommend he buy.

As for will beers like weizens taste right, I don't see how this would change them in any way. I ferment at the same temperatures I would normally, even though with this system you are supposed to have no ill effects at higher temperatures. The only thing I would be worried about in fermenting a hefe-weizen or any wheat beer is the krausen height. I don't think this is an issue though as Poindexter has done some experiments closer to this with his keg ferments.

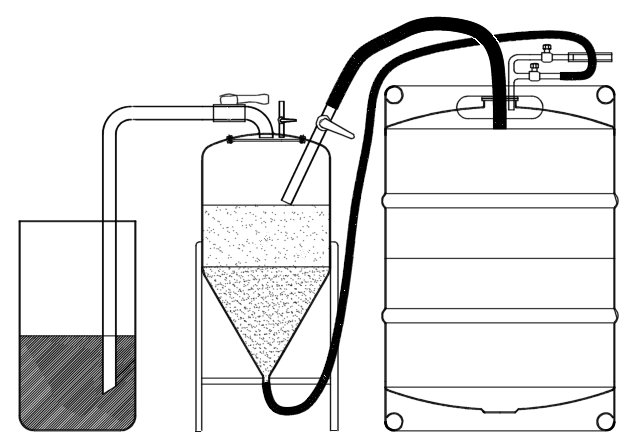

Here is his thread on his ferments both under pressure and with a keg blow off to see how much yeast came out during blow off. I can only "talk" about 12 gallons in a 15.5 gallon fermenter. I never have any problems with anything getting in my spunding valve except when I forgot to set my valve low enough and had to bleed pressure quickly. I got a couple of shots of foam and then after cleaning up the mess it was fine and nothing else made it to the outside of the fermenter.

Temperature swings I couldn't comment on either as I have mine in a temperature controlled lagerator during ferment. I wouldn't think there would be any difference in temperature in any fermentation technique unless yeast activity heat is considered, but I just figure the normal 5-10* core temperature rise of any ferment above ambient.

Lager I haven't tried, but after brewing as many as I have under this technique I am confident it would only benefit a lager more than my ales. Dry or liquid is the same as any other preference. Which ever yeast you would like to use, use it. I am actually thinking of starting to use dry yeast in the future, but am happy now with White Labs liquid.

WBC said:

I made a relief valve and hold at 15 Psi after 3 days @ 65 F wort temperature. I use a Ranco controller to keep it at 62F (in the inside air) but after 4 days I tape it to the Keg. The reason for this is to minimize run time for the compressor and have more stable temperature for the beer. If you tape the sensor to the keg right away it cools the beer way to fast for the yeast. I use WLP001 yeast most of the time for ales and WLP830 for my lagers. In a hurry (Nottingham).

I differ in that I hold my beer at 5 psi during the initial ferment until I am a few points from estimated finish (3-5 days and "estimate" with my refractometer) and then completely un-tap and let the keg fire up to whatever it goes to pressure-wise. After a complete week of primary, I drop to 33* and let sit a week. I am going to stretch this to two weeks total for my next batch and then a week at 33* before transfer to serving keg. I just feel like the yeast can clean the beer up a bunch more and maybe help with my new late clarifying issue on my last two beers. The last two for some reason have not cleared as fast and I think I rushed them too quick into the kegerator. They taste wonderful, but didn't clear until almost floated.

I don't worry about the beer chilling to fast for the yeast as I like to have the beer colder than ferment and let it ramp up to wanted temperature. I have always placed the sensor right on the keg and it has worked wonderful for me. I usually pitch at 60*F and set my controller for 65*F. I also use WLP001 for most all ales, and the next day I am always on temperature and have a strong odor of CO2 in my lagerator. I do have to say though, from what I have researched you could get a much faster ferment at a higher temperature with no noticeable negative results. I am brewing mine for smooth tastes and almost mimic lager brewing in my ales with the obvious differences of cold maturation and shorter primary fermentation times.

My batch before last was a regular single infusion with a mash out decoction. It turned out wonderful and was a fav around my friends. I filled a pig up for payment of a new Sanke keg and drank the rest very fast. I finished at 1.012 right on the money and was very pleased with the outcome of the beer. I anxiously awaited tasting the triple decoction next batch. Same recipe just different hop times at the end and no dry hopping. Wow, this beer was instantly smoother and rounded off flavors in the beginning. It still has a little yeast in suspension after a week in the kegerator and I figure won't clear until the near end like the last one did. Last beer I had in 3 1/6 bbl Sankes, this one is in one 1/2 bbl. I have to say that if you have never done a decoction, try one on your favorite beer recipe that you have brewed numerous times before and tell me how much more the beer tastes. I am blown away, this isn't even the same beer. I am pumped about doing a lager now, but have to wait. I was asked to brew a wedding keg for a friend using the same recipe as the last two, but this time I am going back to single infusion. I have a mighty tasty beverage in the triple decocted APA, but it doesn't taste like APA anymore. This next one will have lots of time to mature before it is even chilled for serving, and I may do a secondary racking to another keg prior to taking to the reception as I don't want to risk the cloudy beer I usually get in my home kegerator for the first couple of pints (well used to until these last two beers anyways).

So, am I happy with my system? Overwhelmingly yes! Does it still need improvement? Hells yeah! I hope the new two week primary at fermentation temperature followed by the week at 33*F for crashing will help me out, and we will see if it does. Until then I can only think filtering for faster beer might be in my future. I have never had to before, but I have also never gone through beer this fast before. I have more people than ever wanting to try it and they all have more than a glass. My hopes are that one of these tasters wants to help me and sees the possibilities of going big. Oh well, the dream remains the same, lol. Hope everyone is enjoying reading about the technique as I have doing it.