ColoHox

Compulsive Hand Washer

I know there are many like it, but this one is mine.

2" mild steel stand with locking casters based on n2fooz design, here is his awesome thread:

https://www.homebrewtalk.com/f51/my-single-tier-build-289260/

High temperature engine primer and paint (painted outside at 40F = bad idea)

3x BG-14 high pressure burners from Bayou

6"x24" 16 gauge heat shield

Camlocks, silicone hose, weldless bulkhead, 2-piece stainless ball valves, sightglasses with thermometers all from Bobby M here,

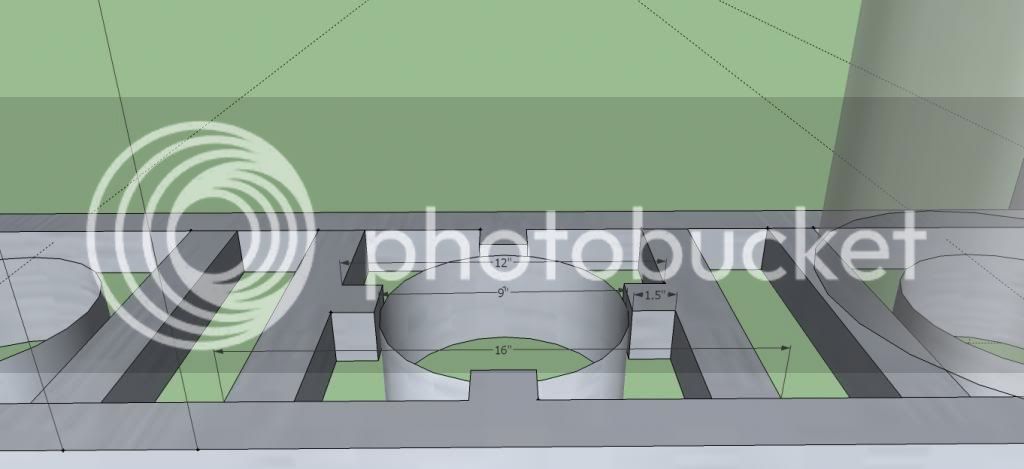

Including his new, hot, full keggle diameter false bottom here

Chugger pump with stainless head

18" Flexible propane hoses from Kurt (onehoppyguy) at Brewsteel

The guys at Visilift for their welding assistance and allowing me to use the shop.

And countless other threads on here, thanks a bunch for being so damn helpful.

And now some beer pron

2" mild steel stand with locking casters based on n2fooz design, here is his awesome thread:

https://www.homebrewtalk.com/f51/my-single-tier-build-289260/

High temperature engine primer and paint (painted outside at 40F = bad idea)

3x BG-14 high pressure burners from Bayou

6"x24" 16 gauge heat shield

Camlocks, silicone hose, weldless bulkhead, 2-piece stainless ball valves, sightglasses with thermometers all from Bobby M here,

Including his new, hot, full keggle diameter false bottom here

Chugger pump with stainless head

18" Flexible propane hoses from Kurt (onehoppyguy) at Brewsteel

The guys at Visilift for their welding assistance and allowing me to use the shop.

And countless other threads on here, thanks a bunch for being so damn helpful.

And now some beer pron