I've got it mostly sketched out... I forgot how the hell I did one small piece though... I'll finish it up tonight and post it tomorrow.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Automated HERMS system

- Thread starter blackheart

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

blackheart

Well-Known Member

kladue - Thanks for the updated picture. I think I am understanding it correctly. Each one of those arrows -> is a connector and -><- is two things being connected together. In that case it appears like the input side of things is very similar to what we have drawn up for our system. The HLT and MLT go into P1 and the MLT and Kettle go into P2. It looks like if you replace the Heat exchanger for the HERMS coil its nearly identical.

What I dont understand is P1 would have to go through the heat exchanger and then to the MLT but also the P2 would need to go through the HERMS coil for cooling. And if using the Kettle to heat the strike water it would also need to be connected to the MLT in as well. I assume using the system you have to heat the HLT for strike water then heat again for sparging water?

We have a NG line running into the brewery. I am not sure what the pressure is on it but its running in from the house on a 1" line.We are planning on using the 200k+ BTU 32 tip type burners. I would imagine we need solenoid valves. How is gas flow controlled with valves? On/off/on/off PWM style or can you open the valve varying degrees?

Cape Brewing - we would love any links or part numbers you have for your valves.

What I dont understand is P1 would have to go through the heat exchanger and then to the MLT but also the P2 would need to go through the HERMS coil for cooling. And if using the Kettle to heat the strike water it would also need to be connected to the MLT in as well. I assume using the system you have to heat the HLT for strike water then heat again for sparging water?

We have a NG line running into the brewery. I am not sure what the pressure is on it but its running in from the house on a 1" line.We are planning on using the 200k+ BTU 32 tip type burners. I would imagine we need solenoid valves. How is gas flow controlled with valves? On/off/on/off PWM style or can you open the valve varying degrees?

Cape Brewing - we would love any links or part numbers you have for your valves.

The symbols in the drawing are solenoid valves labeled "V1-V6 and Fill-Chill, there is no need for plumbing disconnects as plumbing stays connected all the time. The HLT is filled with strike water, and when at temp it is transfered by P-1, then it is refilled with sparge water and reheated. If you want to do RIMS or HERMS just install heater after P-1. When sparging pump P-1 moves sparge water into MLT and pump P-2 moves wort to boil kettle. Save your self some extra work and go for the hurricane burners jetted for natural gas, the 32 tip burners are way to big to use as is. With NG/low pressure LP you can use 24V furnace valves for burner control with standing pilot and thermocouple for flame safety. The adjustable flow valves are quite expensive and usually not needed in this application, and require additional hardware and control signals to work.

Have you determined what control hardware you are going to use to control your system, and how you are going to interface it.

Have you determined what control hardware you are going to use to control your system, and how you are going to interface it.

blackheart

Well-Known Member

The symbols in the drawing are solenoid valves labeled "V1-V6 and Fill-Chill, there is no need for plumbing disconnects as plumbing stays connected all the time. The HLT is filled with strike water, and when at temp it is transfered by P-1, then it is refilled with sparge water and reheated. If you want to do RIMS or HERMS just install heater after P-1. When sparging pump P-1 moves sparge water into MLT and pump P-2 moves wort to boil kettle. Save your self some extra work and go for the hurricane burners jetted for natural gas, the 32 tip burners are way to big to use as is. With NG/low pressure LP you can use 24V furnace valves for burner control with standing pilot and thermocouple for flame safety. The adjustable flow valves are quite expensive and usually not needed in this application, and require additional hardware and control signals to work.

Have you determined what control hardware you are going to use to control your system, and how you are going to interface it.

I have a few questions based on your description.

1. When you heat both the strike and sparge water in the HLT is there a significant lag time between the two? If we wanted to do HERMS and regulate temp then how long would we have to wait until we can start changing the temp from the time the strike water is added?

2. You have the plumbing listed as basically tubes coming out of the kettles and down into the valve system. Does the liquid that sits down in those tubes next to the valves effect anything or is the distance not that far as it looks?

3. Why a hurricane vs the jet burners? We are hoping to upgrade in the future to larger kettles from the kegs. How would a burner be too big?

4. Where can we find the 24v furnace valve? Also, we would now need to create a 24v power source which sounds a bit harder than 12v.

5. The control hardware is going to be a Arduino MEGA or Sanguino micro controller. We have one of each for testing. The mega has an add on ethernet shield and can act as a web server. a basic 4 button interface and 4x20 LCD will be used to display info on the system but all real control and feedback will happen via a web interface or iPhone program. Thats the plan anyway. Currently working on a proof of concept now that can control LED's and display temps.

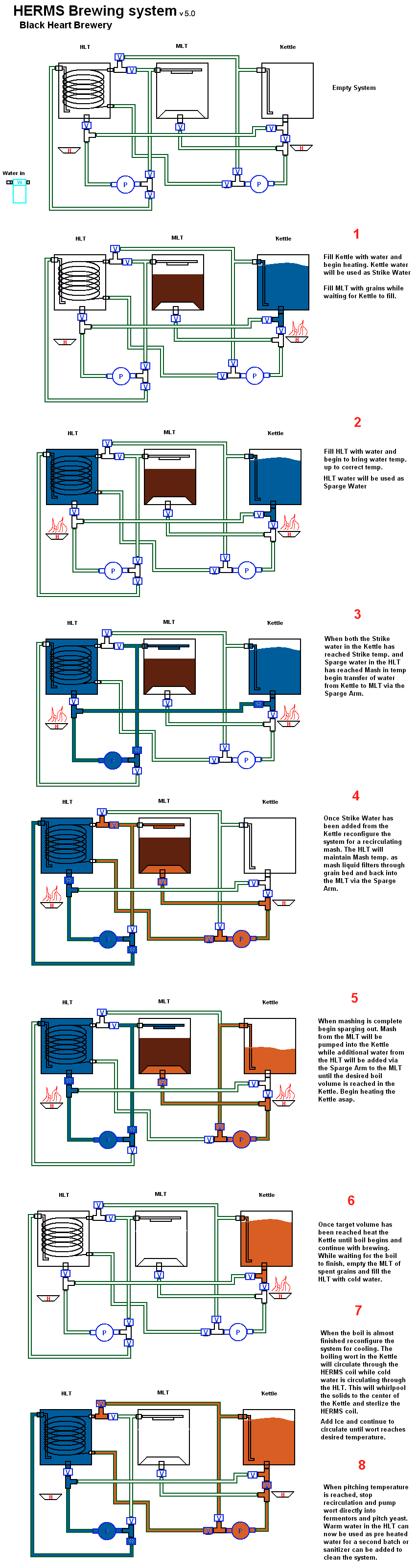

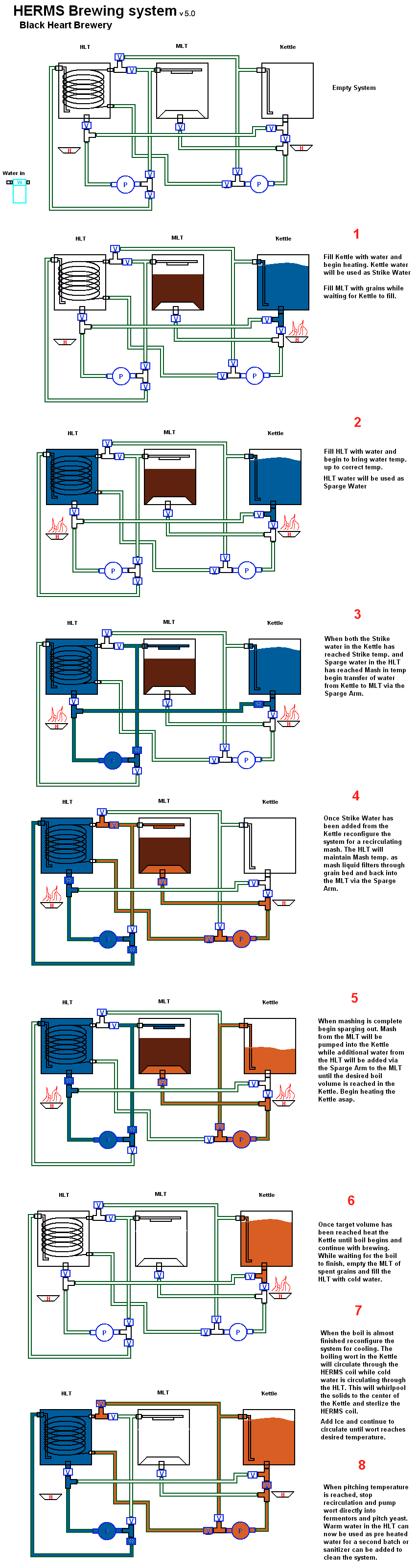

sweet Jesus... it was almost as much work sketching this all out than it was building hte damn thing.

+1 on the 32 tips being too big. I have two 32 tips and I have them on 25 gallon pots... and they're too big. I have then choked WAY WAY down. I had all sorts of burner problems before these so I love my 32's... but they're way too much unless you're going to boil something really off the charts... like 100+ gallons. For anything like 25 gallons or less, the 10-tips should be more than enough. If you're looking at 25 gallons and up.. maybe the 23 tips but the 32's are insane.

I'll get you the part #s off of my gas valves, but that's what I have... 24v furnace valves off of a transformer like Kladue was saying.

+1 on the 32 tips being too big. I have two 32 tips and I have them on 25 gallon pots... and they're too big. I have then choked WAY WAY down. I had all sorts of burner problems before these so I love my 32's... but they're way too much unless you're going to boil something really off the charts... like 100+ gallons. For anything like 25 gallons or less, the 10-tips should be more than enough. If you're looking at 25 gallons and up.. maybe the 23 tips but the 32's are insane.

I'll get you the part #s off of my gas valves, but that's what I have... 24v furnace valves off of a transformer like Kladue was saying.

This is gonna take forever and sorry for highjacking the thread... but you asked...

Here is the overview layout of how fluid flows through

Here is the overview layout of how fluid flows through

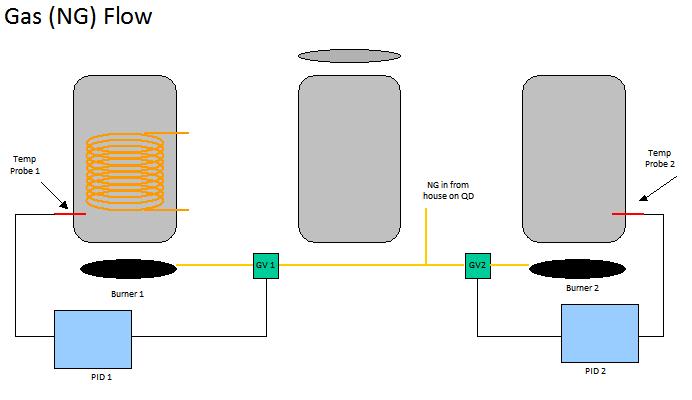

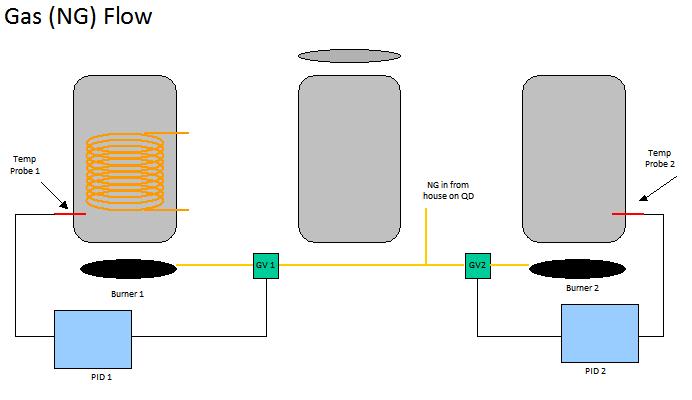

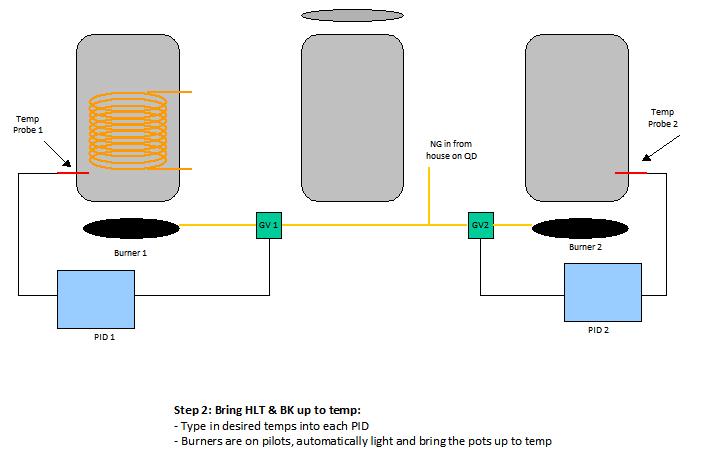

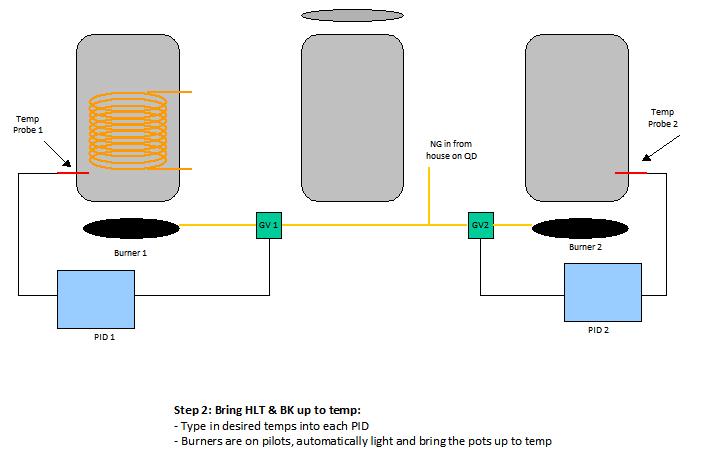

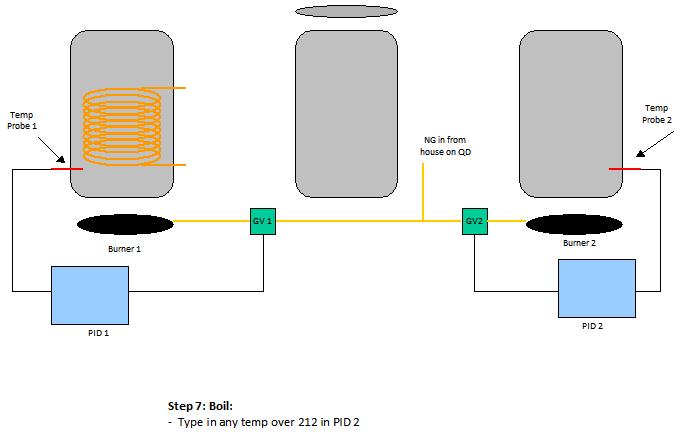

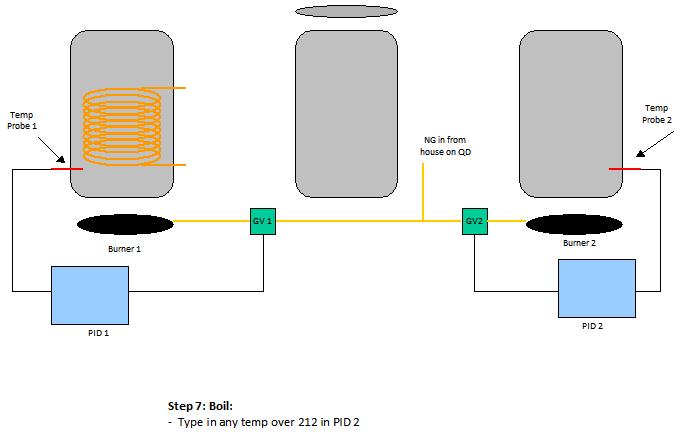

and here is the gas (probably didn't need to sketch it out but screw it)

1234567891

1111111111

blackheart,

1) It takes about 20-30 minutes to heat to sparge temp, and would take considerably less to heat to step temps. you could recirc without passing through the heat exchanger untill the hlt returned to temp with little to no heat loss in that time.

2) the volume that the 1/2 pipe holds is probably less than the dead space in the bottom of your kettles. Temp wise its not a problem since its recircing most of the time and wont cool down much.

3) I have 170,000 BTU burners and have only turned them up all the way once. The fuel usage far outstripped the gain in time, and made the rig dangerously hot to the point of warping rails. The extra 10 minutes is no biggie.

4) I got my furnace controls off ebay- Honeywell 8610U. one needed for each burner.

24 volt transformer- ebay. 100VA if I remember correctly.

3 position switches(installed for emergency manual control)- ebay but picked up local

5) your control hardware sounds very similar to the Brewtroller. You might want to check it out. It is inexpensive and has already undergone fairly extensive beta testing. Up to 32 controllable outputs, fermentation control and data logging. Remote access for control is the current addition they are working on. BrewTroller | BrewTroller

1) It takes about 20-30 minutes to heat to sparge temp, and would take considerably less to heat to step temps. you could recirc without passing through the heat exchanger untill the hlt returned to temp with little to no heat loss in that time.

2) the volume that the 1/2 pipe holds is probably less than the dead space in the bottom of your kettles. Temp wise its not a problem since its recircing most of the time and wont cool down much.

3) I have 170,000 BTU burners and have only turned them up all the way once. The fuel usage far outstripped the gain in time, and made the rig dangerously hot to the point of warping rails. The extra 10 minutes is no biggie.

4) I got my furnace controls off ebay- Honeywell 8610U. one needed for each burner.

24 volt transformer- ebay. 100VA if I remember correctly.

3 position switches(installed for emergency manual control)- ebay but picked up local

5) your control hardware sounds very similar to the Brewtroller. You might want to check it out. It is inexpensive and has already undergone fairly extensive beta testing. Up to 32 controllable outputs, fermentation control and data logging. Remote access for control is the current addition they are working on. BrewTroller | BrewTroller

2222222222

3333333333333

44444444444

888888888888

9999999999999

10101010101010

11 11 11 11 11 11 11

I will try to answer the questions in order:

1, The hlt is emptied and refilled after strike and it will take a bit to heat back up, not a problem with single step as the heat loss will require heat about same time water is hot again.

2, the tubing does not hold much liquid so trapped volume is not too big an issue

3, As to the burners, hurricane burners under HLT and boil kettle, 6" cast burner under MLT. The cast burners offer large turn down over small turn down range with jet burners, more is not better in this case. To big a burner and all you do is burn up the stand and send flames up the side of the keg without doing much heating.

4, look on Ebay or go to HVAC supplier for the valves, Honeywell VR 8200A for standing pilot, Honeywell VR 8345M for electric ignition applications. For pilots use the Honeywell Q314A model for standing pilot, Honeywell Q345a for electric ignition. For Valve power 24VAC -40Va transformer for one valve, 24VAC 100 VA for 3 valves as not all 3 will be in operation at same time.

If you need additional help with the gas hardware PM me and I will help you find the part numbers and sources for the parts. Look at the other Brutus builds for direction in construction so you can avoid problems with your build.

1, The hlt is emptied and refilled after strike and it will take a bit to heat back up, not a problem with single step as the heat loss will require heat about same time water is hot again.

2, the tubing does not hold much liquid so trapped volume is not too big an issue

3, As to the burners, hurricane burners under HLT and boil kettle, 6" cast burner under MLT. The cast burners offer large turn down over small turn down range with jet burners, more is not better in this case. To big a burner and all you do is burn up the stand and send flames up the side of the keg without doing much heating.

4, look on Ebay or go to HVAC supplier for the valves, Honeywell VR 8200A for standing pilot, Honeywell VR 8345M for electric ignition applications. For pilots use the Honeywell Q314A model for standing pilot, Honeywell Q345a for electric ignition. For Valve power 24VAC -40Va transformer for one valve, 24VAC 100 VA for 3 valves as not all 3 will be in operation at same time.

If you need additional help with the gas hardware PM me and I will help you find the part numbers and sources for the parts. Look at the other Brutus builds for direction in construction so you can avoid problems with your build.

12 12 12 12 12 12 12

UGGGG.. that was like freakin' givin' birth.

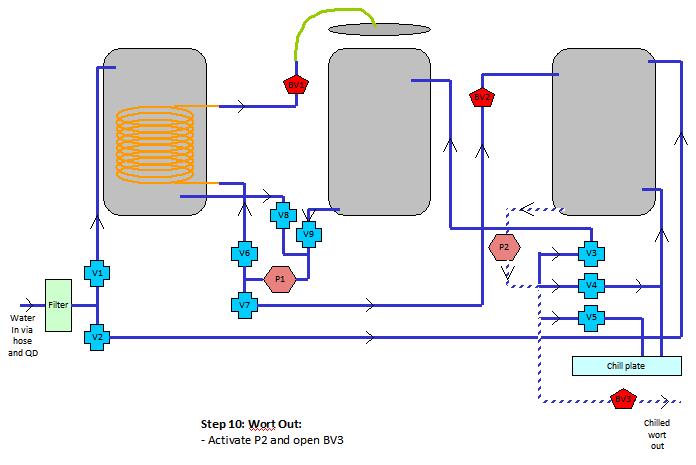

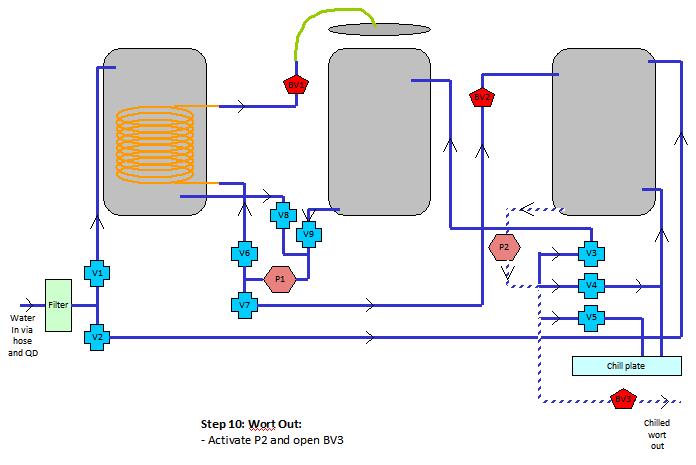

I have three ball valves that are operated manually but BV1 and BV2 are simply flow controls in order to avoid stuck mashes. In an "totally automated" environment, they could be opened to a given flow rate and then just left open. And then the last ball valve is to simply pour your chilled wort out into a fermenter.

I'll grab those part numbers off the valves a bit later

I have three ball valves that are operated manually but BV1 and BV2 are simply flow controls in order to avoid stuck mashes. In an "totally automated" environment, they could be opened to a given flow rate and then just left open. And then the last ball valve is to simply pour your chilled wort out into a fermenter.

I'll grab those part numbers off the valves a bit later

My Honeywell valves are V800's

blackheart

Well-Known Member

Beerthirty, Thanks for the info. We will definitally kick down the burners a bit then. what do you think of these?

I was inspired by the brewtroller to write my own interface with similar hardware. For me, building the system is half the fun! They have a nice system but I want to integrate a little different hardware, namely the ethernet portion which isnt possible with the proprietary PCB they have made.

Cape Brewing. Your pictures were great at explaining you system, I know how long they take to make, I have done it at least 4 times now. I have a Mac but MS Paint is still the best at drawing quick pictures. We are studying your pictures as well as the ones kladue posted and hopefully we will be able to combine both concepts along with our current one and see if we cant figure out a no-change, or maybe a 1 change system.

Hi temp hose will still be used just because it will be easier to move things etc. Also considering Tri-clover fittings. Found a sweet source for them too. Really cool web site I wanted to share with you guys. brewershardware.com They also have digital temp probes that are installed in thermowells already as well as other cool things.

I have a bit of time free this week at work which I am hoping to use to finish the design, have you guys check it once more, then start ordering parts! A significant influx of cash has come our way as I finally got paid for some consulting work I did and it looks like it will be able to cover the parts costs.

Thanks again everyone for the part numbers and pictures!

I was inspired by the brewtroller to write my own interface with similar hardware. For me, building the system is half the fun! They have a nice system but I want to integrate a little different hardware, namely the ethernet portion which isnt possible with the proprietary PCB they have made.

Cape Brewing. Your pictures were great at explaining you system, I know how long they take to make, I have done it at least 4 times now. I have a Mac but MS Paint is still the best at drawing quick pictures. We are studying your pictures as well as the ones kladue posted and hopefully we will be able to combine both concepts along with our current one and see if we cant figure out a no-change, or maybe a 1 change system.

Hi temp hose will still be used just because it will be easier to move things etc. Also considering Tri-clover fittings. Found a sweet source for them too. Really cool web site I wanted to share with you guys. brewershardware.com They also have digital temp probes that are installed in thermowells already as well as other cool things.

I have a bit of time free this week at work which I am hoping to use to finish the design, have you guys check it once more, then start ordering parts! A significant influx of cash has come our way as I finally got paid for some consulting work I did and it looks like it will be able to cover the parts costs.

Thanks again everyone for the part numbers and pictures!

Good luck. For me, building it was half the fun.

I'm hard-plumbed throughout the entire thing with everything connected with unions so if I really want to, I can break the whole thing down into small pieces. The only flexible piece is the high-temp, food safe silicone tubing that connects into the lid of my MLT.

... and everything stays right where it is for cleaning except for the MLT. I take that off to rinse out any straggler grains after shoveling it out (which takes all of a minute). Other than that, everything stays connected and I run boiling water, PBW and star san through it to clean and sanitize. I've done a whole bunch of batches on it at this point and no problems with infections or anything like that.

I'm hard-plumbed throughout the entire thing with everything connected with unions so if I really want to, I can break the whole thing down into small pieces. The only flexible piece is the high-temp, food safe silicone tubing that connects into the lid of my MLT.

... and everything stays right where it is for cleaning except for the MLT. I take that off to rinse out any straggler grains after shoveling it out (which takes all of a minute). Other than that, everything stays connected and I run boiling water, PBW and star san through it to clean and sanitize. I've done a whole bunch of batches on it at this point and no problems with infections or anything like that.

blackheart

Well-Known Member

This is one of the burners we were looking at. It seems they have really good prices. Is this one too big?

8", 20 tip, 150,000 BTUs

They also have a few other models as well.

8", 20 tip, 150,000 BTUs

They also have a few other models as well.

The jet burners use a venturi (Bernouli's law) to mix the gas and air. They can't be adjusted for heat output very well due to this. IIRC

blackheart

Well-Known Member

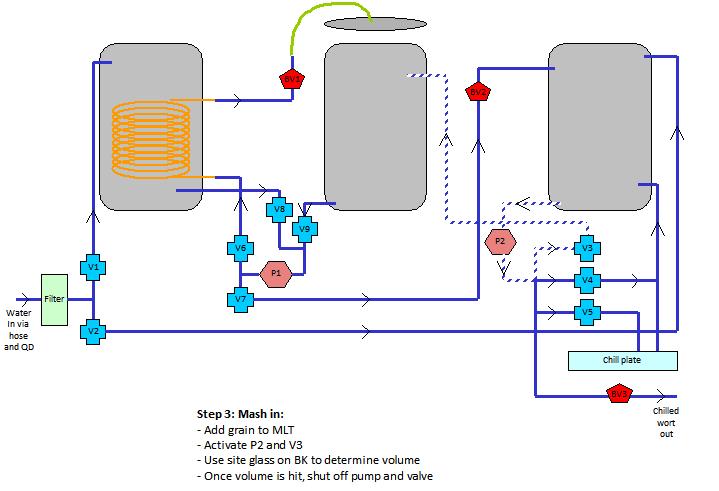

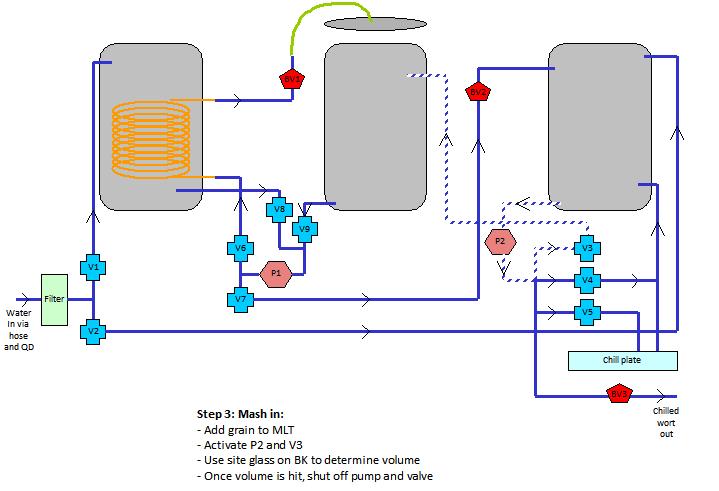

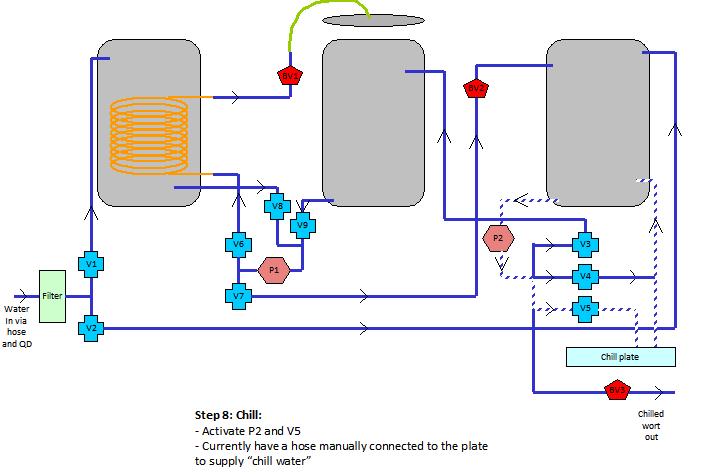

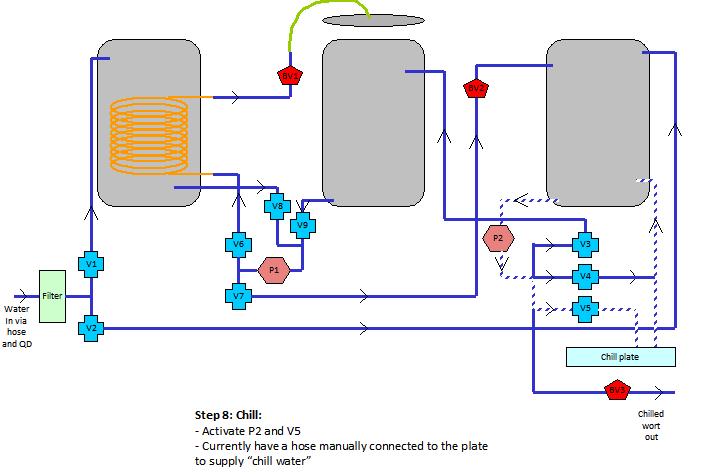

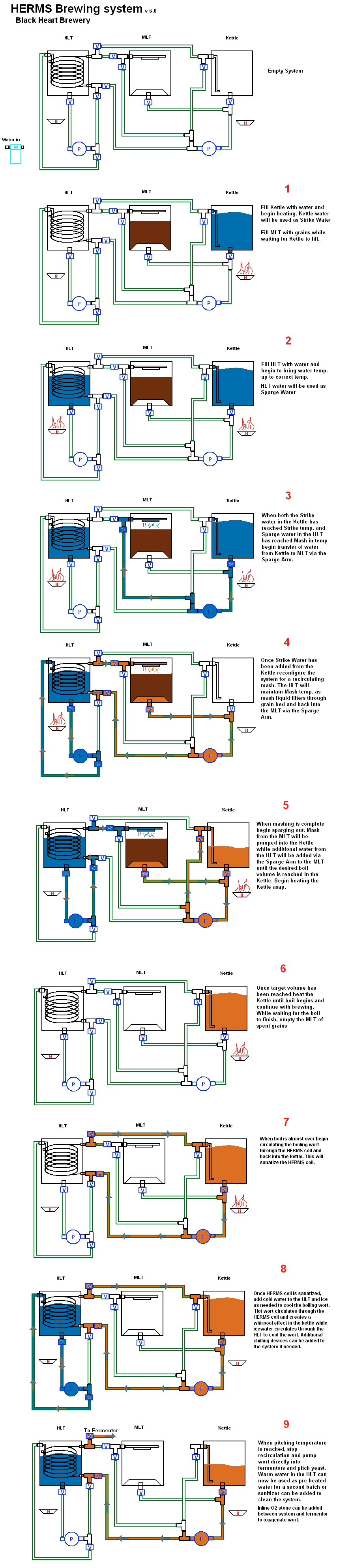

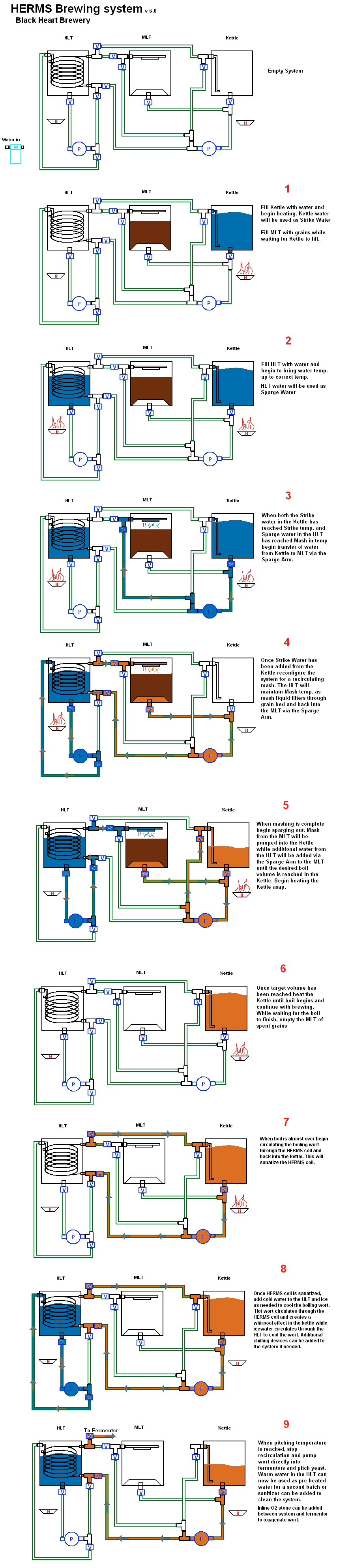

There might be a better way to do this or with less valves (10) but here is what I could come up with today for a HERMS system so that the coil is also used for cooling as a giant counter flow chiller. As a bonus P2 now does the mash recirculation which leaves P1 free to circulate the HLT water keeping the temperature even without the use of a stirrer in the HLT.

There are a few issues with this design of course. One is that it looks much more complex and the paths are a little more round about to get where things need to go. The other is that on both the MLT and Kettle inlets two separate connections need to go into each one. I'm not sure how I would do that without getting some liquid going back in the other direction but it looks like the over all idea works.

I was really hoping that I would not need like 10 valves to fully automate this. If anyone has a suggestion on some pieces I can remove that would be great. Also, I have not automated the filtered water entering the system in this picture which I am not sure how to handle without additional connections and valves.

OK Time to go home for a beer, this thinking stuff is hard!

There are a few issues with this design of course. One is that it looks much more complex and the paths are a little more round about to get where things need to go. The other is that on both the MLT and Kettle inlets two separate connections need to go into each one. I'm not sure how I would do that without getting some liquid going back in the other direction but it looks like the over all idea works.

I was really hoping that I would not need like 10 valves to fully automate this. If anyone has a suggestion on some pieces I can remove that would be great. Also, I have not automated the filtered water entering the system in this picture which I am not sure how to handle without additional connections and valves.

OK Time to go home for a beer, this thinking stuff is hard!

Looking good. Couple of questions. Why does the inlet in the HLT open at the bottom of the kettle? This seems counterproductive during the cooling stage, since most of the HX coil is above this point. In step 7, do you plan of recircing the boiling wort through the HX before adding the water and ice? As joe camel stated it wont sanitize the HX after the cooling water ha been added.

blackheart

Well-Known Member

Looking good. Couple of questions. Why does the inlet in the HLT open at the bottom of the kettle? This seems counterproductive during the cooling stage, since most of the HX coil is above this point. In step 7, do you plan of recircing the boiling wort through the HX before adding the water and ice? As joe camel stated it wont sanitize the HX after the cooling water ha been added.

The HLT inlet is on the the top left so im not sure what your referring to.

During the cooling phase the HLT will recirculate ice water through itself via P1 or possibly the HLT + another chiller. At the same time the wort in the Kettle will circulate through the HERMS coil and back into the Kettle via the inlet which will whirlpool the wort while it is cooling.

we will run the boiling wort through the herms and start the wort recirculation prior to putting any water in the HLT for cooling as suggested. Its a minor change to the specific steps listed and has been omitted from this drawing to save some space. When the wort is cooled we will connect to the fermentors and continue to pump it through the herms and out.

So if we were to go with this design... then I guess I have two questions.

1. What do we do for the MLT and Kettle inlets where 2 things need to be connected to the same inlet?

2. What type of connections are best? if we are making a system that needs virtually no hose changes then are we really going to see a benefit from QD's or tri-clover connections?

and a final question, Full automation would be ideal, but at the cost of 10 electronic valves and many more connectors and fittings vs changing hoses 2-3 times. I'm just trying to think in terms of scalability so we can use the same parts and swap out the pots at a later date, and the ease of other things like cleaning/maintenance.

Boerderij_Kabouter

Well-Known Member

Here is a possible alternative design...

You get away with one less valve and I think you may be able to route the lines in a more attractive manner... who knows.

:EDIT: Pardon my laziness and crappy layout. I am swamped at work and just used this as a 10 minute break. Obviously the routing would be much prettier and the manifolds more practically laid out if you took the time to actually design it.

:EDIT::EDIT: It was driving me nuts. I made it a little better now.

You get away with one less valve and I think you may be able to route the lines in a more attractive manner... who knows.

:EDIT: Pardon my laziness and crappy layout. I am swamped at work and just used this as a 10 minute break. Obviously the routing would be much prettier and the manifolds more practically laid out if you took the time to actually design it.

:EDIT::EDIT: It was driving me nuts. I made it a little better now.

pfft...

yeah... like you're gonna listen to a guy who sniffs donkeys...

I'm not going to get into and argument on the jet-tip burners... I've fought that fight too many times on other threads and everyone tells me I'm wrong adn what I have going in my garage is some kind of mirage or something. So I'm going go to say it just in this single post... I have two 32-tip burners. They run on NG. I run then through two Honeywell V800s and mine are adjustable. If I adjust the gas valve, I can bring my flame down to three inches or if I jack them up, I can get that flame to be 30 inches (seriously). Everyone posts "you can't adjsut those burners"... well... I don't know how I'm doin' it then. My burners DO burn dirty though. I DO get soot on my pots.

My father teaches natural gas heating at a technical college and swears the soot is only there becuase I have the burners too close to the pots and as the gas and flame hit the pot, the pot actually cools the gas enough so that it doesn't fully burn up. According to him... if I simply raised my pots a couple of inches or lowered my burners, I wouldn't have any soot at all.

Since my entire rig is hard plumbed and the burners were the last peices to go it... raising the pots or lowering the burners isn't possible unless I wanted to re-do all sorts of stuff. I probably will someday but in the mean time... my burners are controlled. I CAN adjust the flame and therefore heat output. They DO put out a AZZLOAD of heat even after adjusted way way down and mine DO burn dirty. Given the issues I had with other burners, I LOVE how much heat I get out of my 32's... and if I have to deal with a little soot and not burning my NG as efficiently as I possibly could... I'll live with it.

yeah... like you're gonna listen to a guy who sniffs donkeys...

I'm not going to get into and argument on the jet-tip burners... I've fought that fight too many times on other threads and everyone tells me I'm wrong adn what I have going in my garage is some kind of mirage or something. So I'm going go to say it just in this single post... I have two 32-tip burners. They run on NG. I run then through two Honeywell V800s and mine are adjustable. If I adjust the gas valve, I can bring my flame down to three inches or if I jack them up, I can get that flame to be 30 inches (seriously). Everyone posts "you can't adjsut those burners"... well... I don't know how I'm doin' it then. My burners DO burn dirty though. I DO get soot on my pots.

My father teaches natural gas heating at a technical college and swears the soot is only there becuase I have the burners too close to the pots and as the gas and flame hit the pot, the pot actually cools the gas enough so that it doesn't fully burn up. According to him... if I simply raised my pots a couple of inches or lowered my burners, I wouldn't have any soot at all.

Since my entire rig is hard plumbed and the burners were the last peices to go it... raising the pots or lowering the burners isn't possible unless I wanted to re-do all sorts of stuff. I probably will someday but in the mean time... my burners are controlled. I CAN adjust the flame and therefore heat output. They DO put out a AZZLOAD of heat even after adjusted way way down and mine DO burn dirty. Given the issues I had with other burners, I LOVE how much heat I get out of my 32's... and if I have to deal with a little soot and not burning my NG as efficiently as I possibly could... I'll live with it.

. We are studying your pictures as well as the ones kladue posted and hopefully we will be able to combine both concepts along with our current one and see if we cant figure out a no-change, or maybe a 1 change system.

I'm confused... the design I used is a no-change... (unless I don't know what "no change" means). You mean so that you don't have any manually change connections or anything right?

The only manually things I do are open the ball valve at the end to pour our chilled wort and connect a garden hose from my house into the other half of the plate chiller so cold water gets fed into it...

You seem kinda touchy today cape. I withdraw the laws of physics since you seem to have found away around them.

Blackheart, I was referring to the pipe that appears to go to the bottom of the inside of the HLT from the top water inlet. It appears that the water enters and exits near the bottom of the kettle. I must not be looking at it correctly.

Blackheart, I was referring to the pipe that appears to go to the bottom of the inside of the HLT from the top water inlet. It appears that the water enters and exits near the bottom of the kettle. I must not be looking at it correctly.

Uggg.. not touchy at all... it's just I've been told like 600 times that you can't control those burners and yet I seem to be able to.

I dunno... maybe we're talking about two different things... I'm not a gas guy so maybe I'm thinking about something totally different.

If I take the pots off my rig... light my burners... and turn the adjustment screw on the top of my gas valve one way... the flame will go from three inches to freakin' two and half feet of blue flame... if I turn it the other way... I can get it down to three/four inch blue flame.

Are you saying I can't do that? I'm not being all pissy, I would honestly love to settle this because as I mentioned, I've been in arguments over this a bunch of times in other threads where people tell me that's impossible.

I dunno... maybe we're talking about two different things... I'm not a gas guy so maybe I'm thinking about something totally different.

If I take the pots off my rig... light my burners... and turn the adjustment screw on the top of my gas valve one way... the flame will go from three inches to freakin' two and half feet of blue flame... if I turn it the other way... I can get it down to three/four inch blue flame.

Are you saying I can't do that? I'm not being all pissy, I would honestly love to settle this because as I mentioned, I've been in arguments over this a bunch of times in other threads where people tell me that's impossible.

blackheart

Well-Known Member

Beerthirty. I get what your saying now. I think I was thinking that adding the tub to the bottom of the HLT would create a whirlpool effect that would transfer heat. What is better, whirlpooling the HLT water or just pumping it in the top and out the bottom?

Capebrewing, We liked your design but it does not use the HERMS coil as the chilling device which is partially why we chose the HERMS design.

Boerderij, I think that the v5 that we posted would work better if we moved the valves that are next to the pump out up to the kettle and MLT inlets like you have in your design.

I think that both this v5 design and the v4 design with work, its just a question of automation vs hose changes and the cost of each. Here is a quick overview.

Full-automated v5

20 pairs of disconnects

10 valves

7 T connectors

8 bulkheads

Semi-automated v4

15 pairs of disconnects

4 valves

3 T connectors

so it looks like the cost of going fully automated is going to come down to the cost of the valves which is more than double. I found a pair of tri clover disconnects with a 1/2" male MPT thread on one side and a barb on the other for attaching to hi temp tubing. also includes the clamp to connect them together. $35 a set vs $31 for a SS QD from more beer thats not tri-clover.

20 pairs of tri-clover connectors @ $35 = $700 .... outch...

we are going to end up spending like $2000 on SS connectors and adaptors lol.

8 bulkheads

Capebrewing, We liked your design but it does not use the HERMS coil as the chilling device which is partially why we chose the HERMS design.

Boerderij, I think that the v5 that we posted would work better if we moved the valves that are next to the pump out up to the kettle and MLT inlets like you have in your design.

I think that both this v5 design and the v4 design with work, its just a question of automation vs hose changes and the cost of each. Here is a quick overview.

Full-automated v5

20 pairs of disconnects

10 valves

7 T connectors

8 bulkheads

Semi-automated v4

15 pairs of disconnects

4 valves

3 T connectors

so it looks like the cost of going fully automated is going to come down to the cost of the valves which is more than double. I found a pair of tri clover disconnects with a 1/2" male MPT thread on one side and a barb on the other for attaching to hi temp tubing. also includes the clamp to connect them together. $35 a set vs $31 for a SS QD from more beer thats not tri-clover.

20 pairs of tri-clover connectors @ $35 = $700 .... outch...

we are going to end up spending like $2000 on SS connectors and adaptors lol.

8 bulkheads

Naw buddy. I'm know it is possible. The venturi principle is used in float type carburetors to draw liquid fuel up into the throat of the carb. At different velocities the efficiency will change but fuel is still drawn up(same as in a burner, but with greater ease since the fuel is a gas not a liquid in a burner) In your burner at one point you have optimum fuel/air ratio where at others points the ratio is not optimum for efficient burn. That does not say it wont work, just that you could get more heat with the optimum mix of fuel and air. Other burners use the same principle but both air and fuel can be adjusted where the jet burner can only be adjust for fuel. I dont use the jet burner simply due to economics and was just pointing out the flaw in that design. BTW I was on vaca in PA and googled to see how far away you were hoping to get a chance to meet you and check out your rig. Alas the east coast is larger in areas than I thought it was.

Blackheart, although whirlpooling does move liquid from top to bottom and negate the need for a stirrer. I think better water movement would occur if it was force pumped top to bottom.

Yeah... you're looking at a solid five hours, minimum, from PA up to my neck a' the woods.

blackheart

Well-Known Member

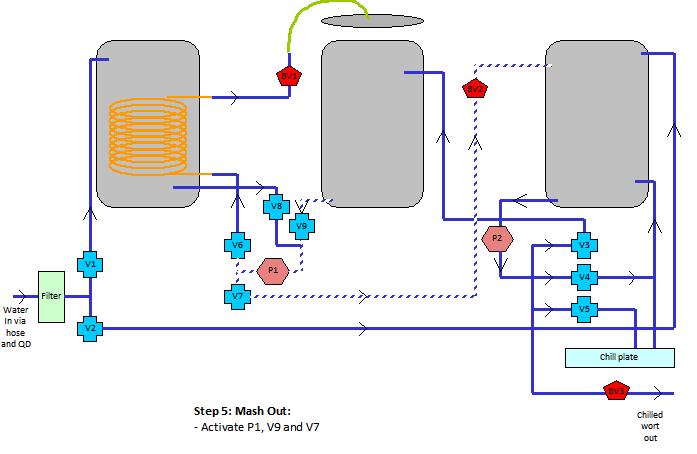

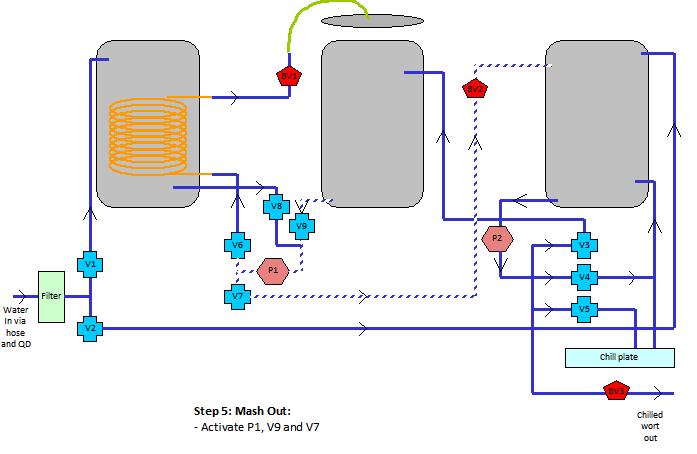

OK so here is version 6!

Here are some assumptions...

- Space in plumbing where liquid COULD go but eventually doesnt because a valve is in the way is negligible and does not hurt anything.

- The HLT does not need a valve as it is the only thing going IN to the pump so if the pump is OFF then the HLT water will go nowhere....

- No hose changes except at the end to connect to fermentor, no point in automating this as the connector going from the HERMS coil out into the Kettle in is already sanitary and long enough and additional things like a O2 stone and inline temp probe may be added.

* I also added the HERMS coil sanitizing step to this picture..... This is *hopefully* the final design and we can start counting parts from this design and order stuff as soon as tomorrow!!!

Thoughts?

Here are some assumptions...

- Space in plumbing where liquid COULD go but eventually doesnt because a valve is in the way is negligible and does not hurt anything.

- The HLT does not need a valve as it is the only thing going IN to the pump so if the pump is OFF then the HLT water will go nowhere....

- No hose changes except at the end to connect to fermentor, no point in automating this as the connector going from the HERMS coil out into the Kettle in is already sanitary and long enough and additional things like a O2 stone and inline temp probe may be added.

* I also added the HERMS coil sanitizing step to this picture..... This is *hopefully* the final design and we can start counting parts from this design and order stuff as soon as tomorrow!!!

Thoughts?

Boerderij_Kabouter

Well-Known Member

Looks sexy to me. The only thing I see is you could cut out is the valve you use in step 3. You could fill the MLT with strike water by pumping through the coil. That would allow you to save some dough on one valve, a tee and some tubing.

It definitely isn't bad to have that extra run in there just a little redundant. I think that looks great now!

Well thought out! You and your pocket book will be happy you took the time to plan it out.

Cheers!!!

It definitely isn't bad to have that extra run in there just a little redundant. I think that looks great now!

Well thought out! You and your pocket book will be happy you took the time to plan it out.

Cheers!!!

blackheart

Well-Known Member

I thought about doing that too... The only issue is the strike water would be hotter than the mashing/sparge water and by passing through the coil would give unpredictable results. We would have to then heat both to strike temperature which would take longer and just waist energy heating water in the HLT that will just need to cool anyway.

Thanks for your input and drawing earlier Boerderij, I think this is about as effecent as we can get at this point. I am happy with the design, and unless I hear otherwise from somone else by tomorrow we are going to go ahead and start ordering stuff we know we need like tri-clover connectors and other pieces.

Thanks for your input and drawing earlier Boerderij, I think this is about as effecent as we can get at this point. I am happy with the design, and unless I hear otherwise from somone else by tomorrow we are going to go ahead and start ordering stuff we know we need like tri-clover connectors and other pieces.

Similar threads

- Replies

- 0

- Views

- 390

- Replies

- 3

- Views

- 977

- Replies

- 4

- Views

- 534

- Replies

- 0

- Views

- 282