Weezy

Well-Known Member

Great build!

The adventure is half the fun...

hey, the electrical panel, is that a sub-panel just for the brewery?

The adventure is half the fun...

hey, the electrical panel, is that a sub-panel just for the brewery?

Weezy said:Great build!

The adventure is half the fun...

hey, the electrical panel, is that a sub-panel just for the brewery?

Great job on the build, it looks fantastic.Thought I would post that the condensation on the vent hood was pretty substantial during the boil. Fortunately I built edging/lips around the bottom of the hood vent to catch the runoff. If I hadn't done this, there would have been condensation dripping off all over the kettles and table and floor. I certainly recommend, if you build your own hood vent, make sure you build in lips around the bottom to catch the condensation drip. Not one drop of runoff hit the table or kettles. I did have to take a towel and soak up the water out of the edging. Thinking I'll drill a small hole on one corner, slightly tilt the hood and then connect in some vinyl tubing so the moisture drains out. Overall, it works well and if you are thinking of building an eHERMS system do not overlook having something like this in your build.

I guess I will close this thread out with these photos of the system in action. Amazing how well it works. 95% efficiency every time. Brewing a hefe in this photo with no rice hulls. Effortless !

KCHomebrew,

Nice work, really like what you have done

I am looking to do something similar.

EBC III & a two vesel version, tryign to do one pump.

I am in the planing stage, two bare walls in a basement, trying to come up with a budget & realistic time frame.( i'd like to brew on mine by x-mas 2014 )

And I was wondering if you had any words of wisdom ?

How long did it take you - from begiing to end ?

Anything you would do different ?

Hoe much did the whole thing cost you ?

Anything you have changed since your last post ?

Do you like the EBC III ?

How is the brewing going ?!

Thanks

Steve

I'm amazed at the 95% efficiency numbers. That's what Kal claims too. I still haven't had a chance to use mine yet. The electrician is supposed to hook up my circuit tonight so I should be able to brew this weekend and test it out. What kind of crush do you use? Course or fine?.

I see you have a high gravity controller have you used it yet and do you like it ?

Sent from my iPhone using Home Brew

I switched to a 1bbl Stout Tanks system and am building heating elements that work with the Brewers Hardware tri clover element adapter.

Main reasons for the switch to a larger system is the ability to brew a larger batch if I so choose, while also still having the flexibility to do 5gal. and 10gal. batches. The 1bbl system allows me to do that.

You can brew 5 gallon batches with 40 gallon kettles? On my 20 gallon Stout mash tun if I go with less that 1.5 qts/pound of grain liquor to mash in I don't even hit the temp sensor. I am amazed you'll be able to hit it in kettles twice the size!!

Also with the ports slowdown on the west coast I wonder what that will do to delivery time?

You can brew 5 gallon batches with 40 gallon kettles? On my 20 gallon Stout mash tun if I go with less that 1.5 qts/pound of grain liquor to mash in I don't even hit the temp sensor. I am amazed you'll be able to hit it in kettles twice the size!!

Also with the ports slowdown on the west coast I wonder what that will do to delivery time?

I'm surprised the chuggers didn't work. It doesn't need to be a vortex to get the trub and hops to cone-up. You can do it with a mash paddle and not a lot of stirring.

Another item I ran into while planning this brewery was the ability to whirlpool a large batch (20gal to 1bbl). I ran some water trials with my chugger pumps on 20gal. and 40gal. amount and it failed to effectively create a good whirlpool. Sadly enough, that meant I had to purchase a larger pump (more $). So, I purchased a March Nano Brewery pump. In reading up on this pump, you've got to think about the fitting sizes and hose sizes you use on the inlet portion of the pump. It's a 1" inlet and a 1/2" outlet. Great thread here where March Pumps actually provides some detail on how to properly use these pumps:

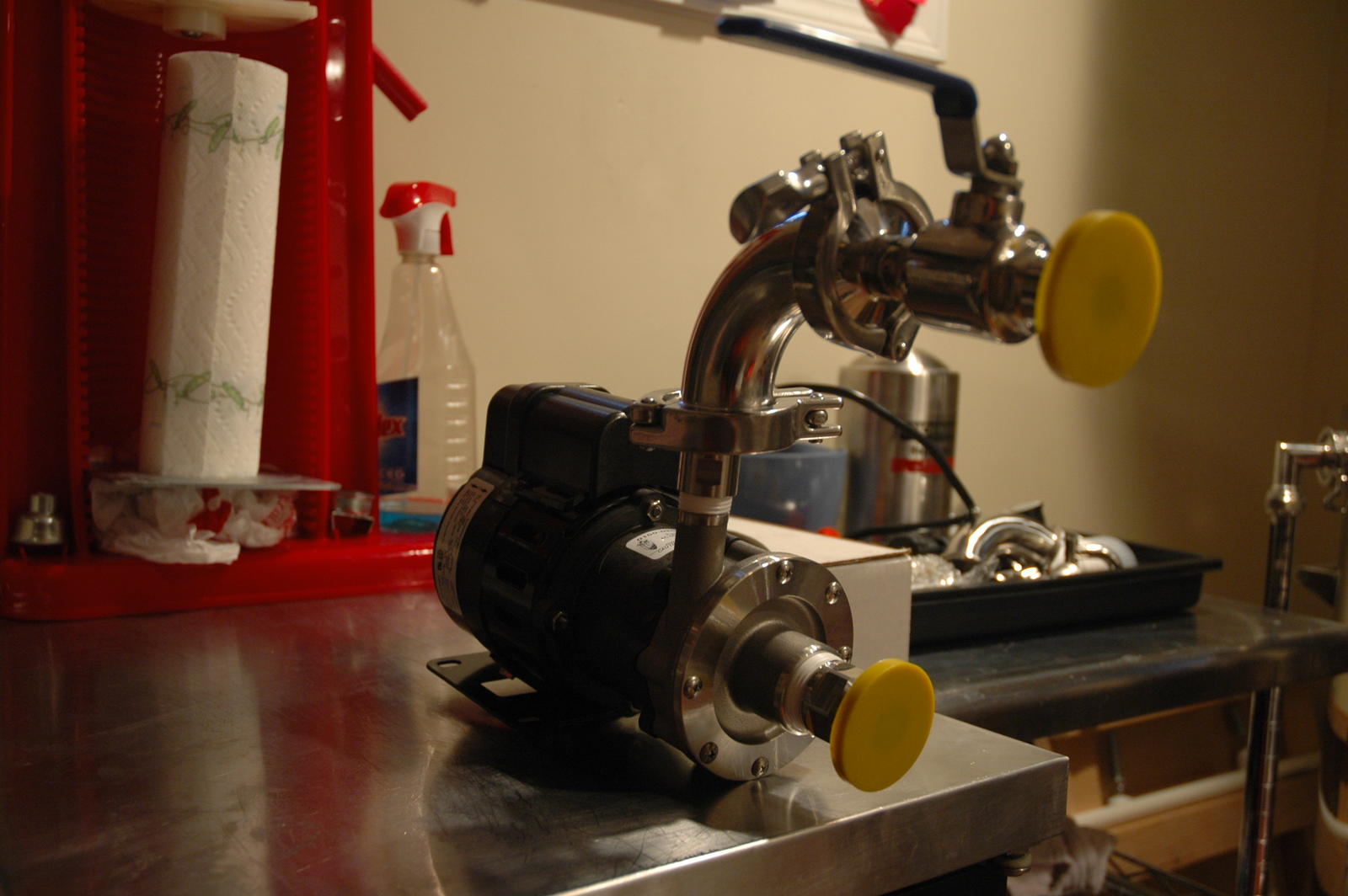

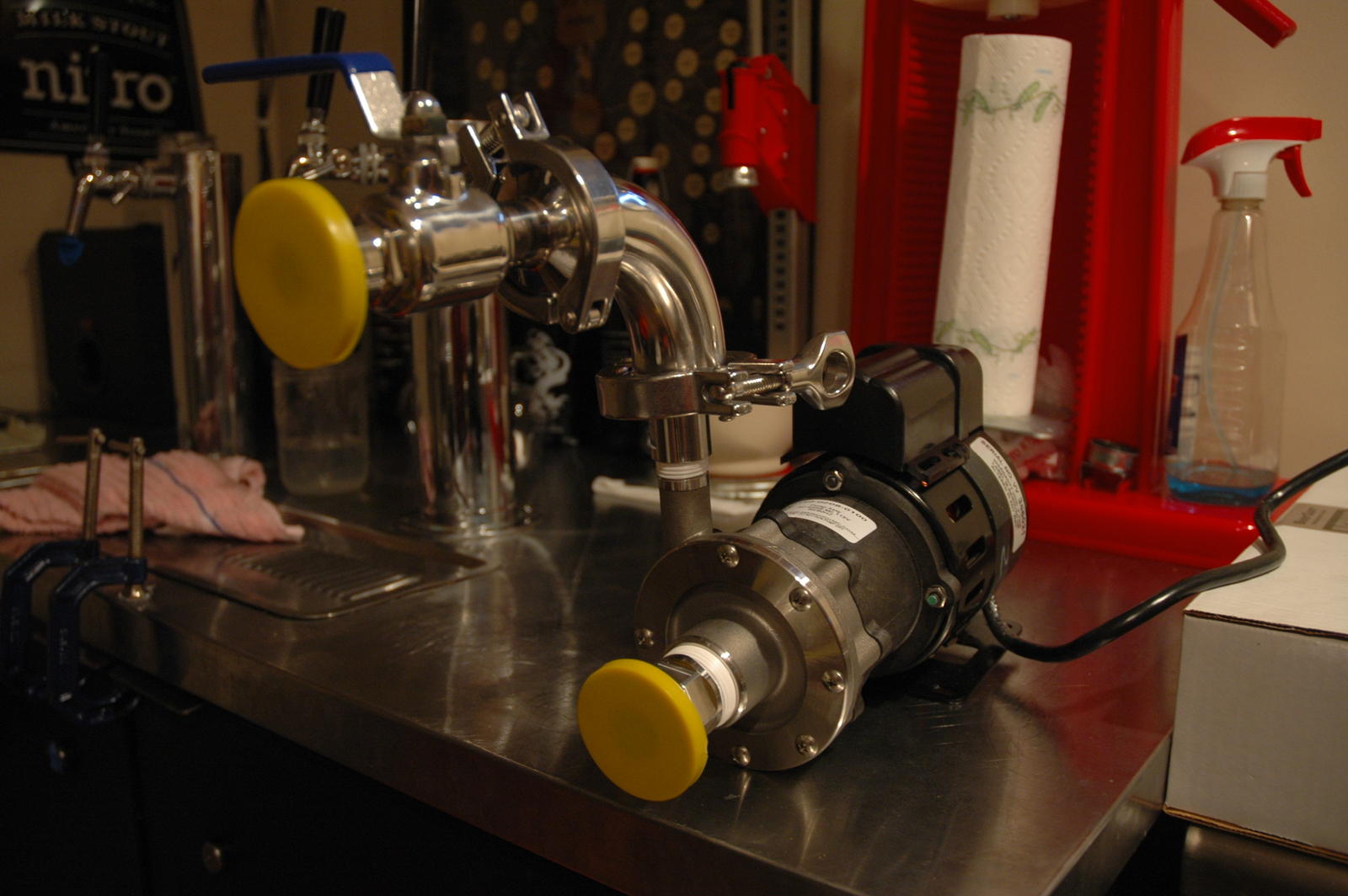

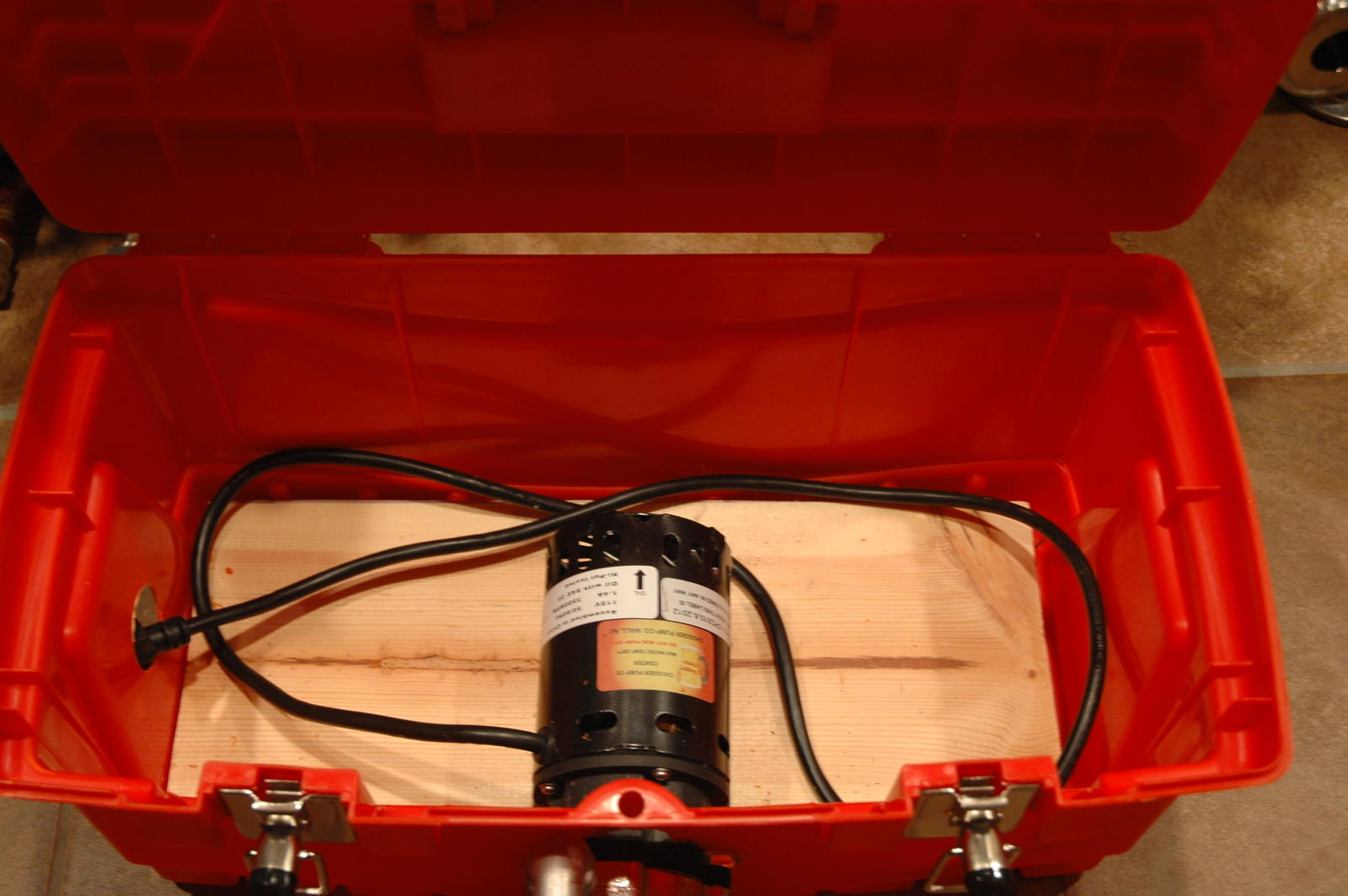

With all of that in mind, I used a 1" tri clover threaded inlet piece and then used 1/2" outlet threads. Connected with a 90 degree elbow and a 3/4" (5/8" ID) ball valve that will run the whirlpool on the boil kettle. I'll be using 3/4" ID silicone tubing for the inlet (along with 3/4" tri clover barbs on the BK outlet and pump inlet) and then using 1/2" braided silicone tubing for the outlet that feeds the tangential inlet on the BK. If anyone has ideas on a pump housing that I could build for this thing, let me know. I'm in search of a plastic tool box that would fit it. Haven't found one yet. Might just make a wood enclosure with caster wheels. Here's a pic of this huge pump:

If you want to get every last bit out of the nano pump find a weldor and have tri clamp fittings mated right up to the volute and discharge port. I can do full throttle whirlpool with these now right after flame out now whereas with any fittings or 1/2" id hose(or 3/4"id) on the suction side it would cavitate a bit and I would have to throttle it back.

http://s9.photobucket.com/user/w_strassburg/media/Beer/1023132207a.jpg.html

Enter your email address to join: