jbsengineer

Well-Known Member

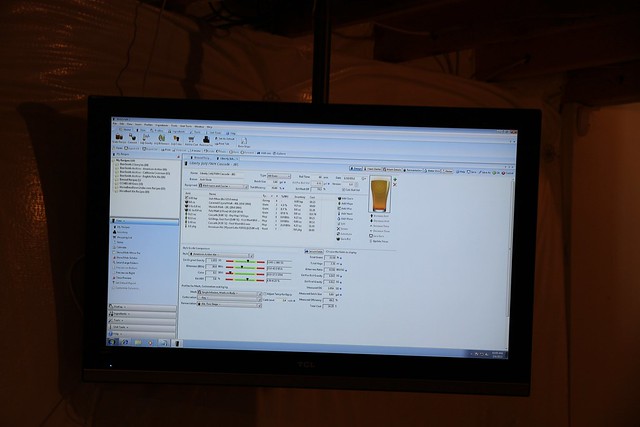

I have officially gotten wife approval. I will be building an electric brewery in the basement. It will be another Kal clone. I ordered the control panel kit tonight! So excited!!!

Pictures of the space to be posted soon. And I hope to document the steps as I build it out!

Pictures of the space to be posted soon. And I hope to document the steps as I build it out!

!

!