chuckjaxfl

Well-Known Member

I am abandoning the DIY PWM project.

A few weeks ago I bought an Arduino UNO, and have really taken to it. The PWM seems like very, very low hanging fruit now.

I though the Arduino was a specific type of microcontroller, or chip, or board. I just knew that it was over my head. What I now know is that the Arduino is not really a specific product, more of a project. The best way I can relate it is to think of America Onlne in the '90s. It took the Internet, put an intuitive, EASY to use face on it, and introduced the masses. Arduino does the same thing for the microcontrollers. You can buy one, watch a few YouTube videos, read a few examples and be working in a few hours.

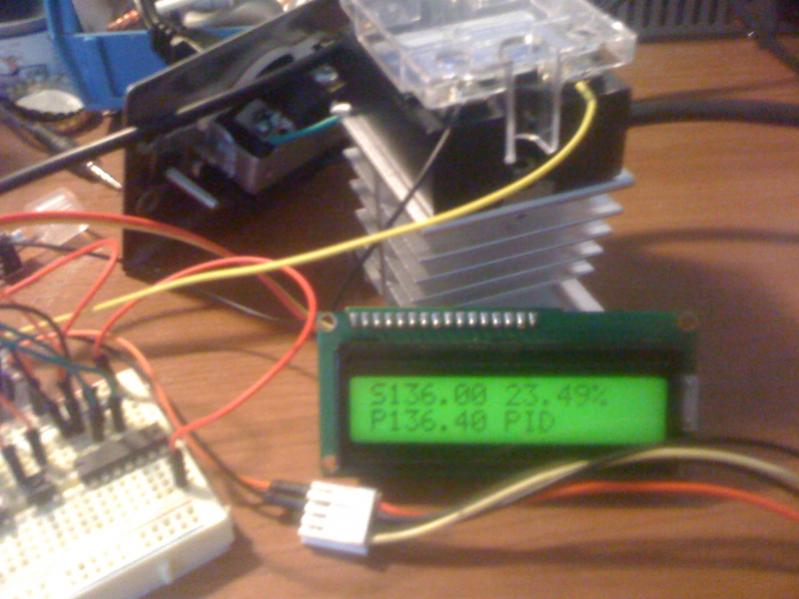

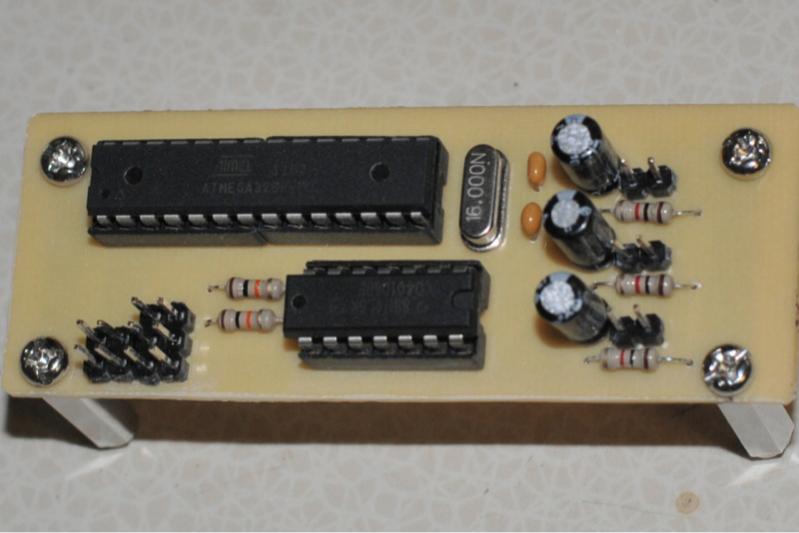

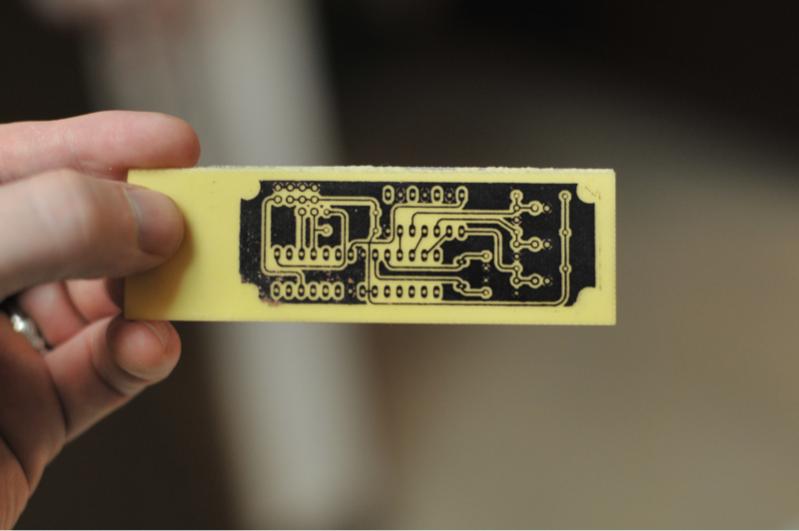

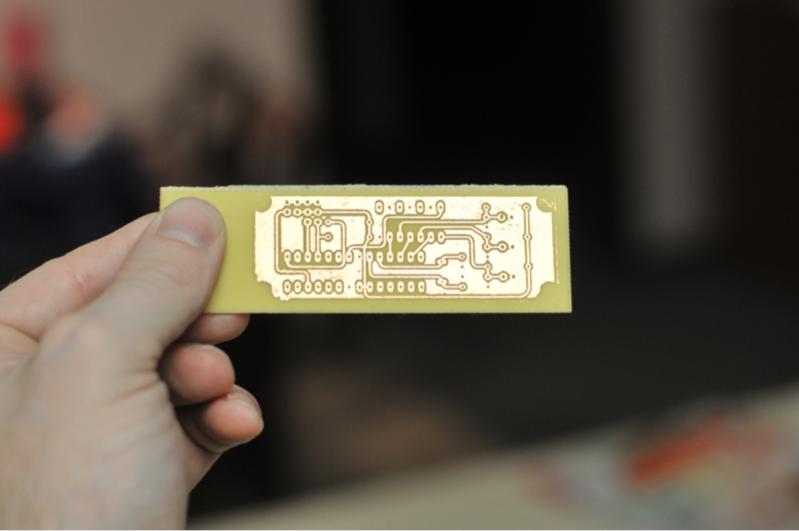

In my case, I started with a sensor and an LCD display. I added the PID library a few days later, and then the autotune library. I've since connected it to a simple 115 outlet and a crockpot, which I've been using to cook sous vide successfully. Since it was all working on the breadboard ok, I started drawing a little PCB for my buttons, sensor header and such, and then learned that you don't really even need the Arduino part of the Arduino anymore once you've got all the kinks worked out. You can just pull the chip from the Arduino and install that in your project, instead. Get a new $4.30 chip for your Arduino and start all over on a different project.

I wish I had been taking more pictures all along to show you guys. I'll post ones that I have.

A few weeks ago I bought an Arduino UNO, and have really taken to it. The PWM seems like very, very low hanging fruit now.

I though the Arduino was a specific type of microcontroller, or chip, or board. I just knew that it was over my head. What I now know is that the Arduino is not really a specific product, more of a project. The best way I can relate it is to think of America Onlne in the '90s. It took the Internet, put an intuitive, EASY to use face on it, and introduced the masses. Arduino does the same thing for the microcontrollers. You can buy one, watch a few YouTube videos, read a few examples and be working in a few hours.

In my case, I started with a sensor and an LCD display. I added the PID library a few days later, and then the autotune library. I've since connected it to a simple 115 outlet and a crockpot, which I've been using to cook sous vide successfully. Since it was all working on the breadboard ok, I started drawing a little PCB for my buttons, sensor header and such, and then learned that you don't really even need the Arduino part of the Arduino anymore once you've got all the kinks worked out. You can just pull the chip from the Arduino and install that in your project, instead. Get a new $4.30 chip for your Arduino and start all over on a different project.

I wish I had been taking more pictures all along to show you guys. I'll post ones that I have.