I'm not sure if this has been discussed but....

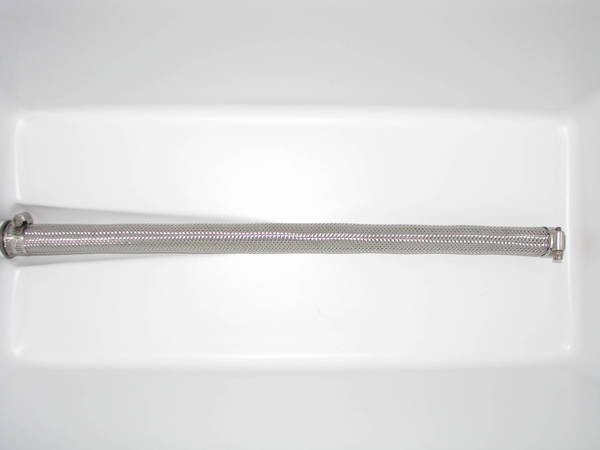

I'm about to build my first official mash tun (4 AG brews and LOTS of frustration later) I cant make up my mind on which method to use. I have seen alot of builds on both SS washer hose style and CPVC/copper manifold and I cant make up my mind. I dont question the safety of the materials used or how to make a mash tun specifically but, which style has proven itself to be the most efficient. I have been "winging it" the past 4 brews and I have made some GREAT beers but they have not been without high blood pressure, sweat, and alot of wire hanger/blow back style of mashing. I'm done with that. I am an uber doityourselfer and must build my own but I am really tired of messing with a part of brewing that seems so simple. I just wanted to gather some opinions regarding what style some of you use and some results.

I am open to some ideas and suggestions.

I am going to use the blue monster on wheels (not sure of kind of cooler) for my tun. It has a flat bottom with a small "valley" for drainage. It seems like one should build the manifold to the cooler but I could be wrong. I always end up with alot of wort at the bottom that I cant get out.

What do you think?

I'm about to build my first official mash tun (4 AG brews and LOTS of frustration later) I cant make up my mind on which method to use. I have seen alot of builds on both SS washer hose style and CPVC/copper manifold and I cant make up my mind. I dont question the safety of the materials used or how to make a mash tun specifically but, which style has proven itself to be the most efficient. I have been "winging it" the past 4 brews and I have made some GREAT beers but they have not been without high blood pressure, sweat, and alot of wire hanger/blow back style of mashing. I'm done with that. I am an uber doityourselfer and must build my own but I am really tired of messing with a part of brewing that seems so simple. I just wanted to gather some opinions regarding what style some of you use and some results.

I am open to some ideas and suggestions.

I am going to use the blue monster on wheels (not sure of kind of cooler) for my tun. It has a flat bottom with a small "valley" for drainage. It seems like one should build the manifold to the cooler but I could be wrong. I always end up with alot of wort at the bottom that I cant get out.

What do you think?