- Joined

- Feb 11, 2008

- Messages

- 97

- Reaction score

- 0

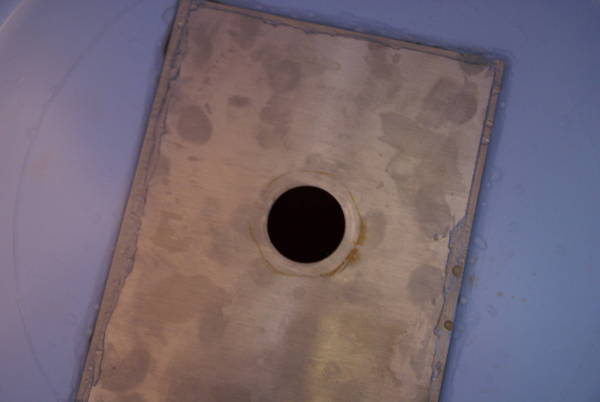

Long story short, I cut too large a hole in the HLT cooler, but had access to some stainless steel to patch it. Everything is fine with leaking but now the the stainless seems to be developing rust. Does anyone have a solution to this? I would be happy to not have to buy a new cooler.