ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

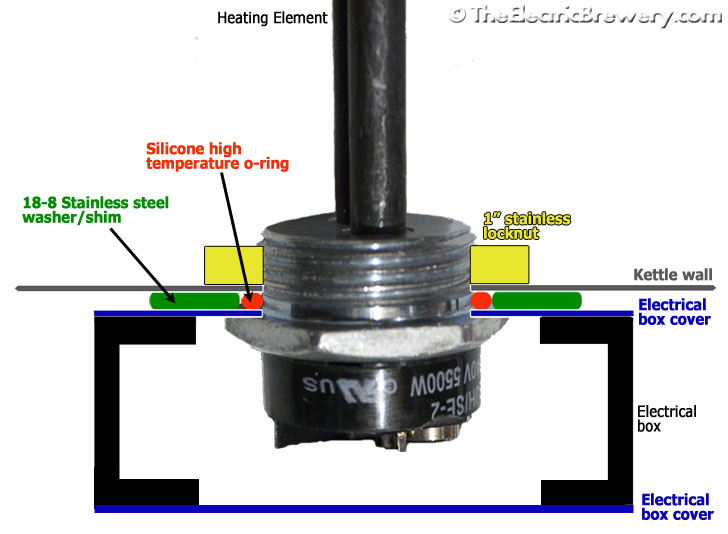

Another thing to note...

To mitigate the risk you mention of potential leakage into the box, I drilled a ~1/4" hole in the bottom of the box to act as a drain port in the event of any leak. I figured in theory there could never be enough buildup of water (from a leak) that would ever allow the water level to rise to the point of the terminals -- plus I find myself checking to see if I have any leaks periodically throughout my brew day. I was super paranoid about that, so it keeps me at peace rather than have to worry about killing myself for a batch of beer. :cross:

This is a good idea....I'd drill 2 holes in the bottom so you can relieve pressure. If the box is completely sealed, it may not drain through just one hole because the vacuum will prevent the fluid from draining.