ReeseAllen

Well-Known Member

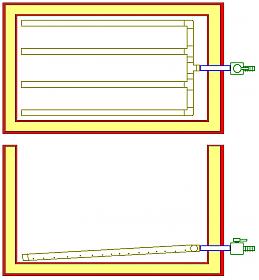

I built an MLT a few weeks ago out of a 10 gallon rectangular Coleman cooler. So far it's worked alright, but it has a lot of dead space. The spigot is mounted high enough that there's about 2 gallons of dead space below it that I'm not able to drain from my copper tube manifold. The manifold is not soldered, so it's easily disassembled and cleaned, but that means I can't siphon with it. And I have no plans to solder it up; I don't have a torch and don't want to blow the $ to buy one just for a quick solder job.

What I would like to do is plug up the existing spigot hole and drill a new hole in the bottom of the cooler. I always set the MLT up on a table when I brew, so hanging it off the edge a few inches to accommodate the bottom-mounted spigot would be easy. I also store it up on a shelf where it'd be easy to just hang it off the edge a bit. I think that I could prop up the other end of the MLT with a half-inch thick piece of plywood, giving all the liquid a nice downhill path to the spigot. I figure if I do both of these things I will eliminate the dead space almost entirely.

I'm looking for tips and suggestions on this undertaking. I have in my tool arsenal an ordinary cordless drill and a small dremel. What tools/techniques would be best to cut a nice clean, round hole through the bottom of the cooler? I'm sure someone's already done this successfully.

What I would like to do is plug up the existing spigot hole and drill a new hole in the bottom of the cooler. I always set the MLT up on a table when I brew, so hanging it off the edge a few inches to accommodate the bottom-mounted spigot would be easy. I also store it up on a shelf where it'd be easy to just hang it off the edge a bit. I think that I could prop up the other end of the MLT with a half-inch thick piece of plywood, giving all the liquid a nice downhill path to the spigot. I figure if I do both of these things I will eliminate the dead space almost entirely.

I'm looking for tips and suggestions on this undertaking. I have in my tool arsenal an ordinary cordless drill and a small dremel. What tools/techniques would be best to cut a nice clean, round hole through the bottom of the cooler? I'm sure someone's already done this successfully.