kal

Well-Known Member

It's so friggin' cold out today (around 3F with wind chill) and it's only November. I'm really questioning if I should put my future 10 gallon electric setup I'm designing in my non-insulated/non-heated garage. I won't enjoy brewing for the 4-5 cold months of the year (0-40F) and the 2-3 summer months won't be fun either as it gets crazy hot (80-100F) in the garage.

Brewing's supposed to be fun right??

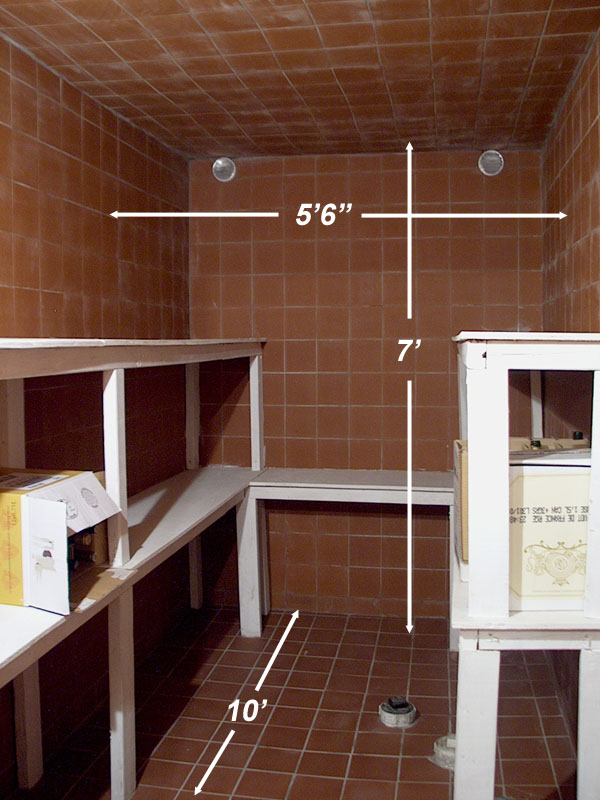

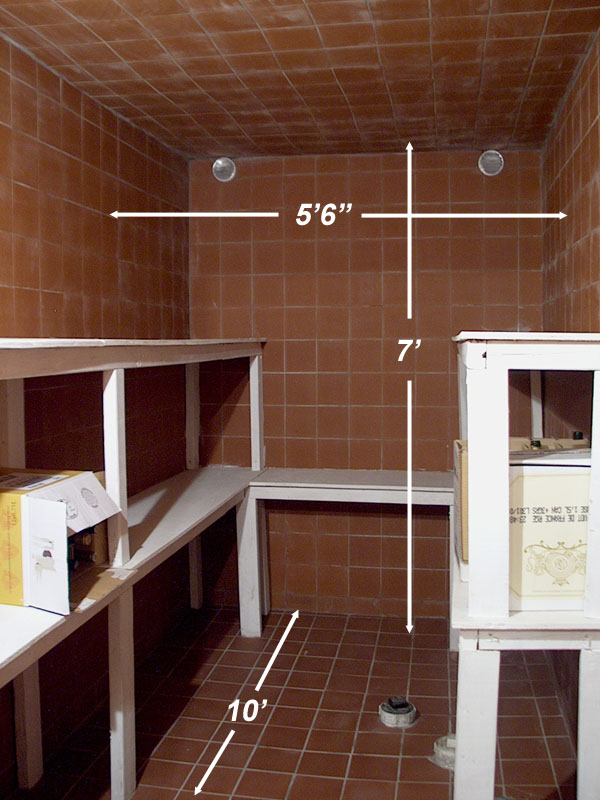

So in my basement I have a terracotta lined "cold-room" under my front step:

Why not remove some of the shelves and built a brewing setup in here?

A vent hood would go in a corner and push steam out one of the 4" vents near in the ceiling seen in the second picture.

I'd have to put water/electricity in the cold room but that's not insurmountable. The water main and electrical panel are litterally 2 feet on the other side of the wall.

For electrical I would put a ring of electrical conduit around the ceiling plus a nice 40-50A 240V plug for the brew stand. All done to code, with GFCIs, etc.

I could even hardline the water into the HLT and whatever chiller system I end up with. There's already a drain in the floor (thankfully as that would be have been considerably more difficult).

Also no need to lug carboys or other things up/down stairs through the house to the garage (fermenation and other 'beer work' is done right next to the cold room).

My only concern is the size of the room. It's not huge so there could (would?) most likely be condensation during a 10 gal full wort boil even with the vent hood pulling steam out as fast as possible. The room itself would be ok (it's 100% terracotta lined and the door is solid core meant for external use) but what about the electrical stuff? Would this be like trying to run a toaster in a steam bath/sauna? I'm thinking more of the safety concerns than comfort.

Thoughts guys? What would you do? There's some extra wiring/plumbing costs involved to go here vs the garage but I don't care about that.

Kal

Brewing's supposed to be fun right??

So in my basement I have a terracotta lined "cold-room" under my front step:

Why not remove some of the shelves and built a brewing setup in here?

A vent hood would go in a corner and push steam out one of the 4" vents near in the ceiling seen in the second picture.

I'd have to put water/electricity in the cold room but that's not insurmountable. The water main and electrical panel are litterally 2 feet on the other side of the wall.

For electrical I would put a ring of electrical conduit around the ceiling plus a nice 40-50A 240V plug for the brew stand. All done to code, with GFCIs, etc.

I could even hardline the water into the HLT and whatever chiller system I end up with. There's already a drain in the floor (thankfully as that would be have been considerably more difficult).

Also no need to lug carboys or other things up/down stairs through the house to the garage (fermenation and other 'beer work' is done right next to the cold room).

My only concern is the size of the room. It's not huge so there could (would?) most likely be condensation during a 10 gal full wort boil even with the vent hood pulling steam out as fast as possible. The room itself would be ok (it's 100% terracotta lined and the door is solid core meant for external use) but what about the electrical stuff? Would this be like trying to run a toaster in a steam bath/sauna? I'm thinking more of the safety concerns than comfort.

Thoughts guys? What would you do? There's some extra wiring/plumbing costs involved to go here vs the garage but I don't care about that.

Kal