Kerberbb

Well-Known Member

I am in the process of starting to acquire pieces for an all-electric keggle brewery. I am wanting a HERMS setup and will be utilizing some existing equipment. Here is a list of components that I have so far, please tell me what else I need, one of which is a control box I know.

ON HAND

2 un-cut kegs

1 keggle with 1/2 barb & themometer (Brew Kettle)

False Bottom

March pump

Copper Heat Exchange

2 Ranco Controllers

What I Think I need

2 weldless ball valves

2 weldless thermowell kits for ranco controller probes

5 Quick Connector 1/2" MPT

3 Quick Connector Barbed

2 Quick Connector Barbed Elbow

1 Input manifold (Tee)

2 1/2" Ball-Valves

10 ft of 1/2" Braided Hose (ft.)

2 Sets of SS Hose Clamps (4 per Set)

2 Heating Elements w/ cord and plug (1 for HLT & 1 for Brew Kettle)

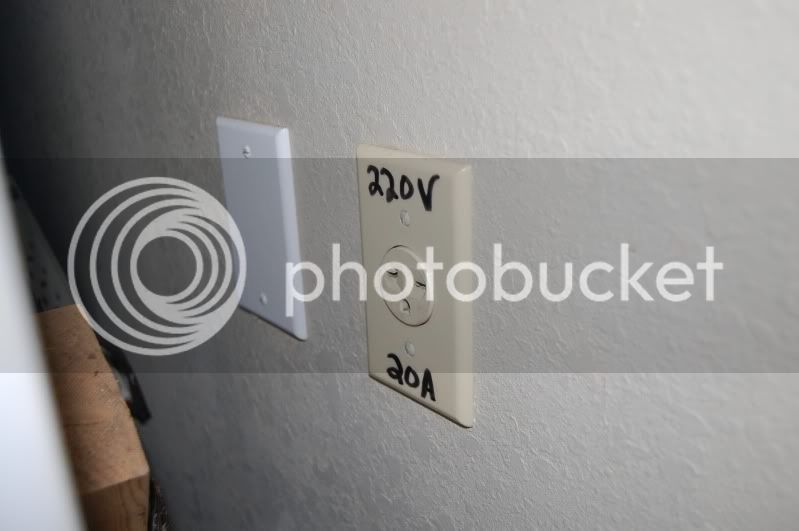

Electrical Box Control to plug everything into (I need direction here)

Can anybody give me some good advice. I can familar with electrical wiring and can do my own DIY. Just a good direction would be advantagous!

Thanks!

ON HAND

2 un-cut kegs

1 keggle with 1/2 barb & themometer (Brew Kettle)

False Bottom

March pump

Copper Heat Exchange

2 Ranco Controllers

What I Think I need

2 weldless ball valves

2 weldless thermowell kits for ranco controller probes

5 Quick Connector 1/2" MPT

3 Quick Connector Barbed

2 Quick Connector Barbed Elbow

1 Input manifold (Tee)

2 1/2" Ball-Valves

10 ft of 1/2" Braided Hose (ft.)

2 Sets of SS Hose Clamps (4 per Set)

2 Heating Elements w/ cord and plug (1 for HLT & 1 for Brew Kettle)

Electrical Box Control to plug everything into (I need direction here)

Can anybody give me some good advice. I can familar with electrical wiring and can do my own DIY. Just a good direction would be advantagous!

Thanks!