Now this interests me. What is your setup like. Are the five probes on separate vessels? Separate chambers? Airflow?

Different things at different times. They are constantly logging once per minute. So, sometimes I have ambient, chiller, water bath, keg, etc. just depends what I'm interested in.

Enough with the bickering. I want to see numbers. I'll change how I do it if someone can prove their way is better. Heck, I'll run my chamber on my STC-1000 and get a good PID to cycle a fermwrap to keep temps up if it would make a big enough difference.

Can Do. I wouldn't say prove, but everyone has their own preference. This is mine.

It depends on how you are chilling. Air as a medium is very different than water. Much more thermal mass in water. As a result, water can have much greater carry over. This also depends on where and how you control the temp. I'll post a few examples. Some of these I've posted in other threads.

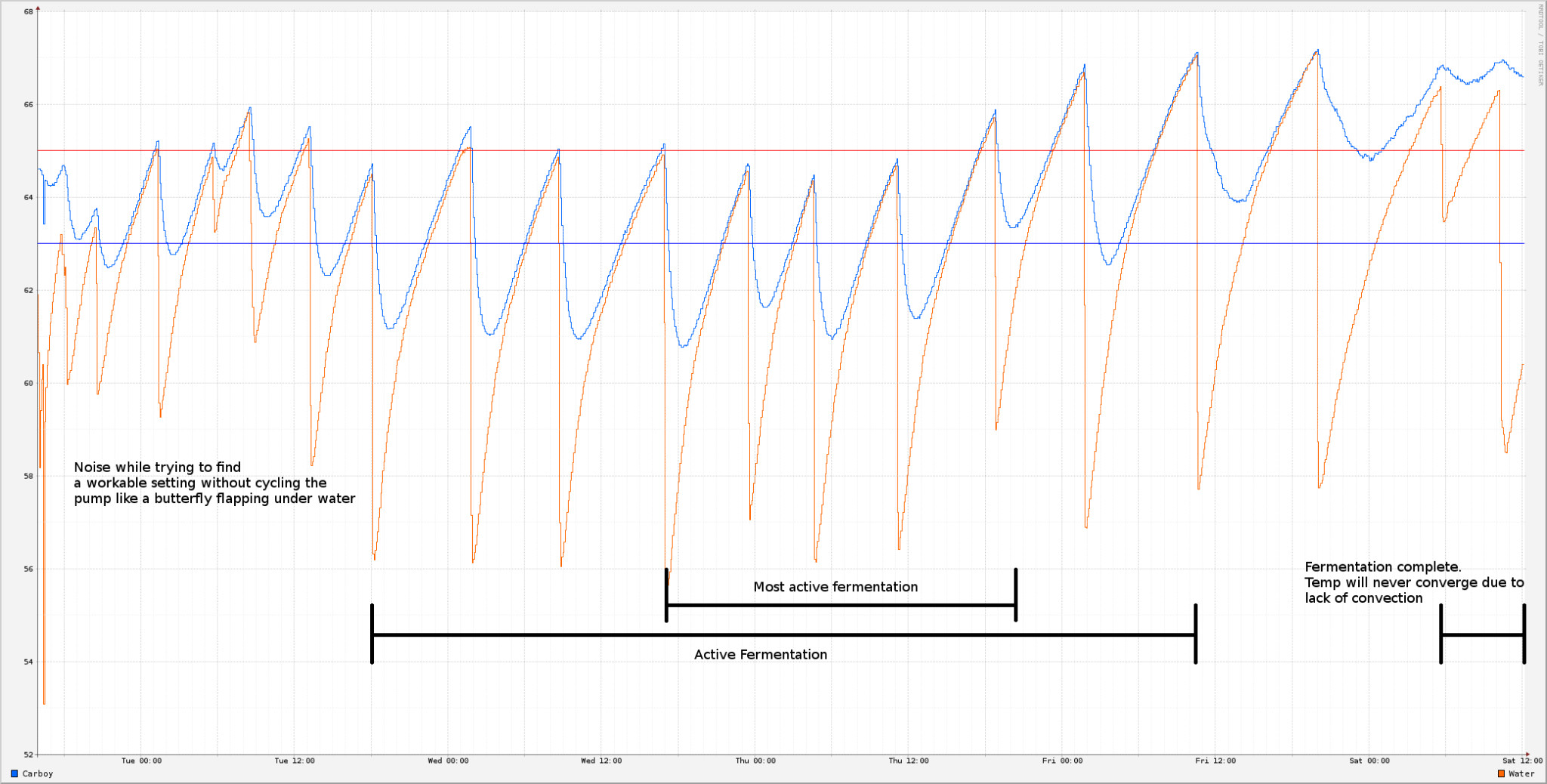

First up This is what happens when the temperature controller is attached to the side of the carboy (glass in this case) measuring the beer temp. The water circulating through the water bath was in the 50's.

Here is the problem: the water bath cools to the 50's very quickly. The beer takes awhile to drop to the set point on the temp controller. Once it clicks off, the delta between water bath temp and beer temp is quite large. The beer continues to cool, the water bath warms up, until either equilibrium is reached, or the controller trips again. This is an example of what not to do, and it looks like this:

Beer temp measured at core

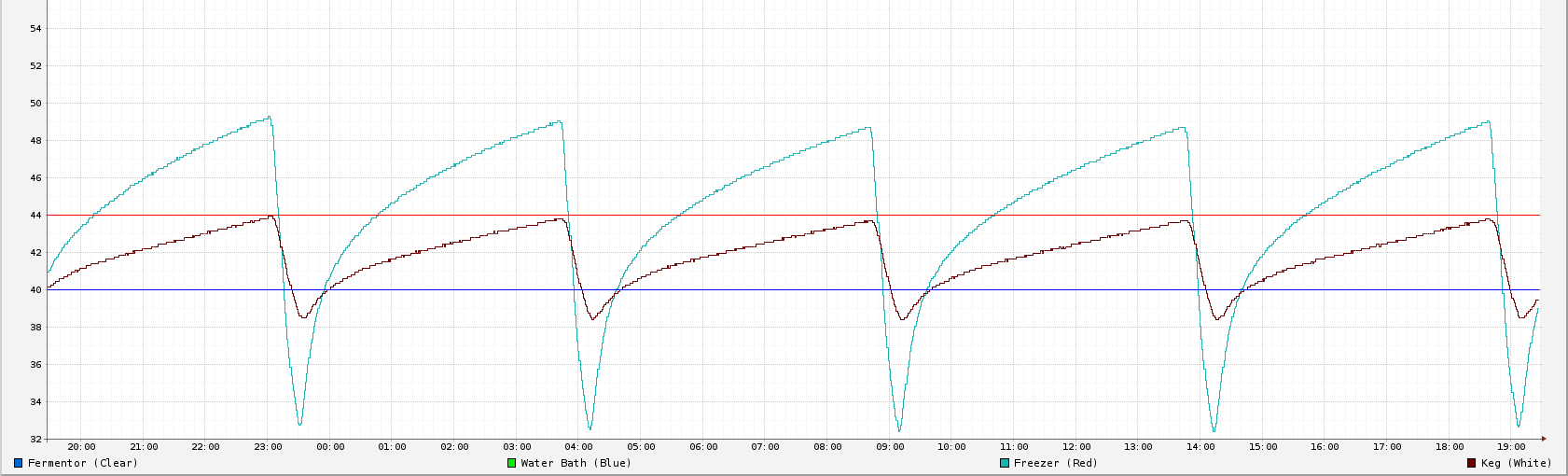

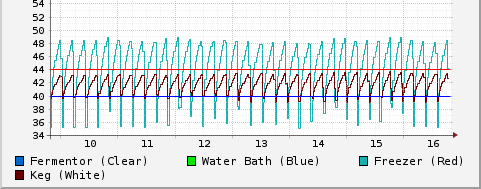

Air is interesting because you can get away with huge swings in ambient temp with much smaller deltas in beer temp. This is handy for those times when you open a refrigerator or freezer. Air has low heat capacity. So, a keezer can have a wide setting on the temp controller, and still maintain relatively constant beer temps. Same is true for fermenting, but I found the water bath transfers heat much quicker. Those wild cycles look like this, and are quite interesting. Over a long period, you can see the effect of ambient room temp on freezer efficiency.

Beer temp measured on side

The low points in the blue freezer temp are directly related to ambient room temp.

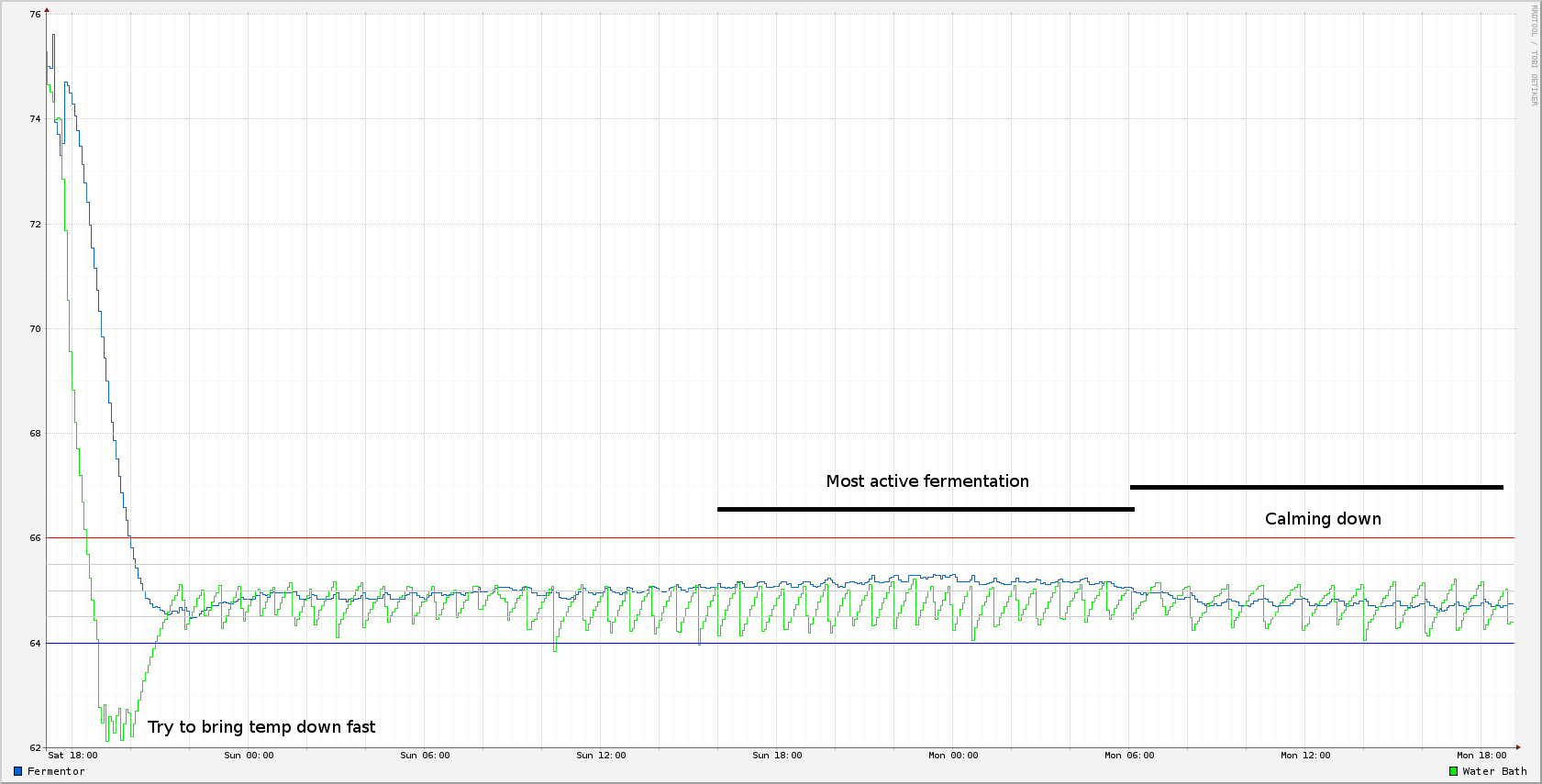

The final step was to control the temperature of the water bath by putting the temperature controller probe into the cooling medium, and ignoring the beer core, or side temp completely. This works very well. The cycles are short. If you tried to keep it this tight in air, I think the compressor would cycle like a hummingbird and burn out in a day.

Beer temp measured at core

Moral of the story, controlling the temp of the cooling medium has always worked better for me, but you have to tune it to your setup. Air can give you a wider margin to work with. I prefer water.

I'm currently doing this with re-frozen bowls of water using a couple small pumps to keep the bath constantly circulating, injecting cold water only when needed per the temp controller. Next I will use a refrigerator coil which should be much more reliable and consistent.