Swagman

Well-Known Member

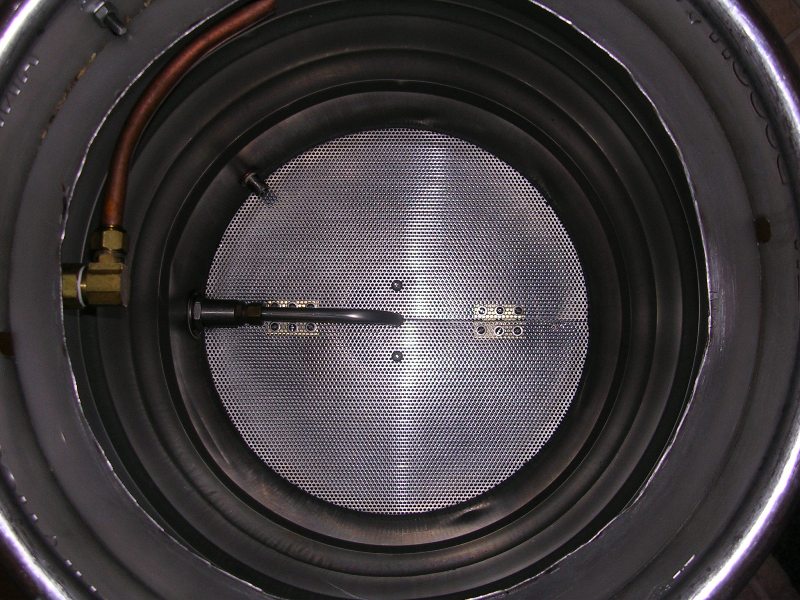

I came up with an ideal couple of years go. Instead of loosing open area with a hinge, I came up with a way of installing the whole bottom into a keg without much effort.

By cutting two slits 180 degrees from each other the false bottom will slip into keg with no problem. Once inside it can be turned to fit flat into the bottom. Most kegss run about 14 15/16 diameter but they are all not the same. That measurement will get you below the bottom weld seam.

I changed the perforated SS sheet to 5/32 x 3/32 stagger and its 1/16 thick. So it will support without legs in a standard keg. I Cut with a plasma cutter from a standard 4 x 8 sheet for kegs only. But all kegs are not the same; I have found some that are welded off in the bottom seam. Some need a little work on the belt sander.

Here are some pictures showing the process.

Dominus Vobiscum

Swagman

By cutting two slits 180 degrees from each other the false bottom will slip into keg with no problem. Once inside it can be turned to fit flat into the bottom. Most kegss run about 14 15/16 diameter but they are all not the same. That measurement will get you below the bottom weld seam.

I changed the perforated SS sheet to 5/32 x 3/32 stagger and its 1/16 thick. So it will support without legs in a standard keg. I Cut with a plasma cutter from a standard 4 x 8 sheet for kegs only. But all kegs are not the same; I have found some that are welded off in the bottom seam. Some need a little work on the belt sander.

Here are some pictures showing the process.

Dominus Vobiscum

Swagman

Dumb question, but how do you remove the dip tube or FB? Seems like the FB would stop the dip tube from spinning so you could unscrew it, and you couldn't remove the FB until the dip tube was out? /

Dumb question, but how do you remove the dip tube or FB? Seems like the FB would stop the dip tube from spinning so you could unscrew it, and you couldn't remove the FB until the dip tube was out? /