Walker - I believe that you said this outright (but i can't find this within the thread).

Do you need an SSR or Temp probe if you are running the PID in manual mode for the boil only? MY current plan is the get the wiring set up, and get the PID and hook up to the element and run in manual mode at whatever percentage to get my boils taken care of. Down the road I will be adding things up into the herms (similar to what you have set up.

i.e. I am looking at the stuff I need from auberns to get the bare bones for my boil set up.

I never said you didn't need an SSR for manual mode PID operation, and I didn't *exactly* say you didn't need a temp probe.

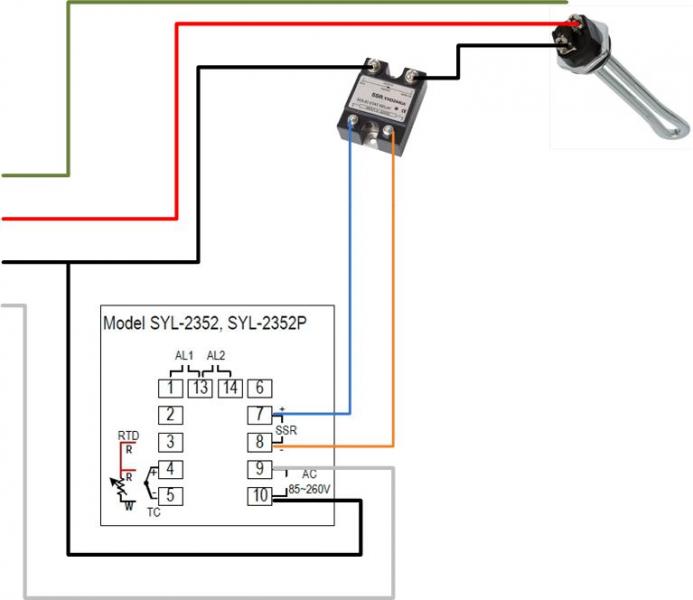

If you want your PID to be in control of the element, you need an SSR. The SSR is the thing that handles the heavy load of the element. The PID is the thing that tells the SSR when to turn on and when to turn off.

Here's the deal with the temp probe, and (IMO) this is a slight design flaw in the PID. The PID will not operate without a temp probe connected to it. Period. The display will show "EEEE" to indicate an error. But, the reason I consider this a flaw in the design is that the temp probe, when in manual mode, is useless. The temp being read by the probe has no impact on what the PID does. The PID just turns the element on and off based on the setting you program in, and it doesn't matter if the temp probe is reading -100*F or +100*F or whatever.

So, the probe has to be connected to the PID, but the probe does not need to be installed in the kettle. You can just leave it sitting on the table or whatever.

Now... the other thing I said about boiling was based on earlier parts of this thread when you were considering using a 3000W element (and I am not sure what size element you are considering at this point.) Anyway, what I said was that 3000W is a really nice sized element for boiling 5 gallon batches, and you can literally get away with NO CONTROL at all. You could plug a 3000W element straight into the wall for 5 gallon batches and just let it run at full strength. No PID. No temp probe. No SSR. No control panel of any kind. Just plug and rip.

If you are going 3000W, you literally won't need anything at all from Auber to get an electric boil kettle in operation for 5 gallon batches. If you are going 5500W, then you probably will want the ability to dial down the boil strength, and that's when you need the SSR and the pulse width modulation that the PID offers in manual mode. And, because of the 'flaw' in the PID, you will also need a temp probe.

- I thought that I should snarf up a couple of the things I knew I would have to buy... but like you said, I should only be buying the rewiring stuff for the house, not the controller hardware!

- I thought that I should snarf up a couple of the things I knew I would have to buy... but like you said, I should only be buying the rewiring stuff for the house, not the controller hardware!