Corona is "fired on". They screen print with a special ink that is then heated up (I believe to 1,200 degrees or so) inside a conveyor oven (a leer) and it becomes "embedded" in the glass. It is impossible to remove the print afterwards, unless you want to take some glass off with it. I doubt that oxi-clean would do anything to it.

There are other printing ink options, most notably so-called "cold inks" that cure using a catalyst, at about 280 degrees F. They have good chemical and physical resilience, but there are chemicals that affect them (notably oils), and you can scrape the print off with a razor, but without damaging the glass. They are not super-toxic, and the latest generation of my favorite glass ink doesn't even contain any VOC's anymore.

I'm an experienced bottle printer (34 years in the business) and I would say that a brewer trying to print their own beer bottles is like me trying to brew my own beer. You'll encounter many variables you had not thought about, and it will quickly turn into an exercise machine. I have to echo mforsman's caution.

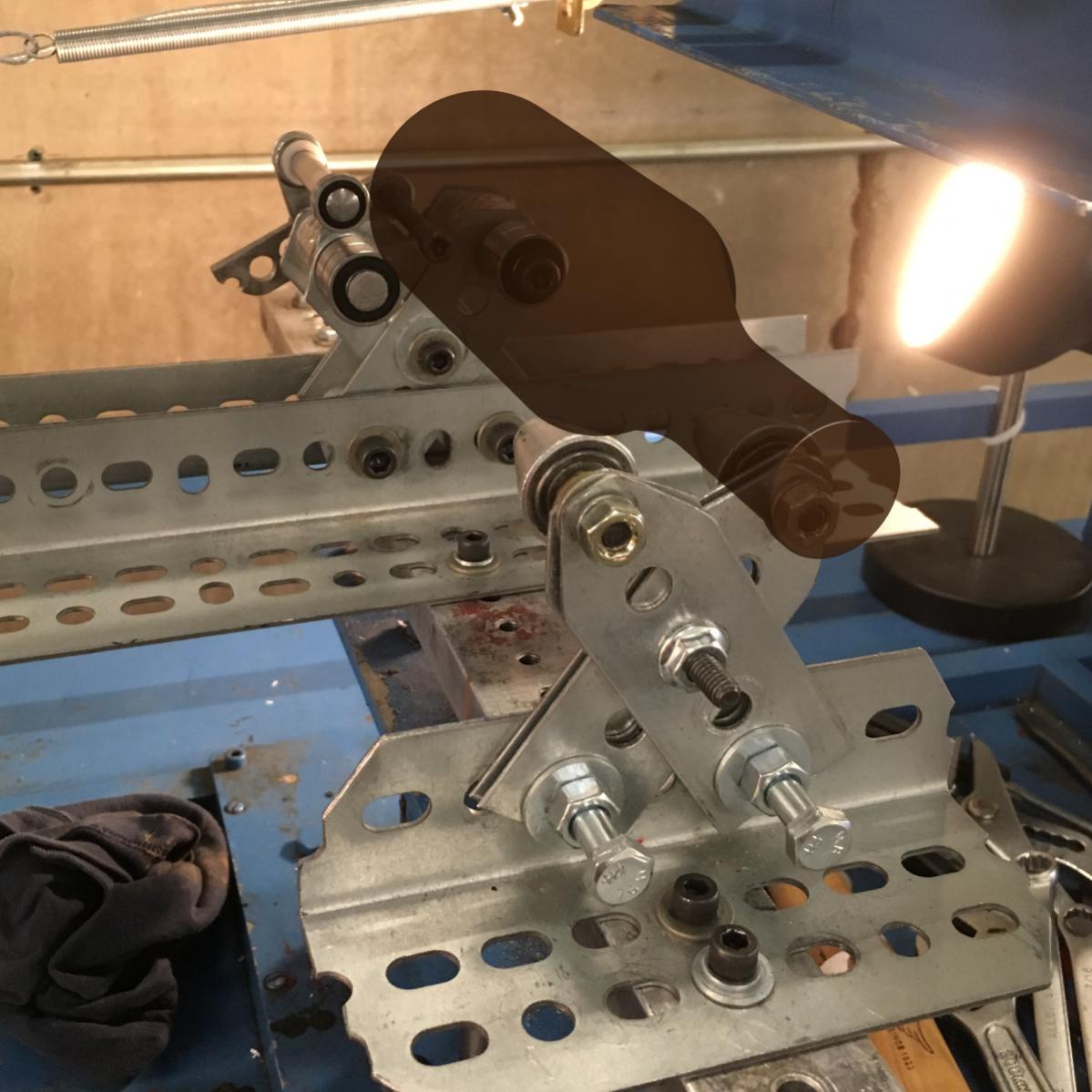

IF you're crazy enough to try, attached is a basic functional roller setup. I started building these things myself from hardware store parts, because the OEM ones that come with cylinder presses either suck and/or are really expensive to replace. In the front, you use conical rollers with bearings, in the back just straight bearings. It's a simple but super-adjustable scissor setup. The harder part will be to create a consistent screen slide, and a mount for the squeegee. In cylinder printing, one of the things to keep in mind is that the squeegee needs to hit the screen just right of center in the direction of print, relative to the apex of the cylinder. Also, make sure there's a back stop to keep your bottle in the same plane, and make sure the rollers are not touching the ink you're laying down. Those perforated straps I used are a little flimsy, so I made sandwiches out of them and they support any weight now.

dallasdb, if you're still looking at bottle printing options, let me know, I'm also in Aurora, CO and I have a bottle print shop. I can print beer bottles all day. My equipment supports up to a 32 oz bottle (I can print larger, but my dryer can't handle larger).