I picked up the Danby DAR044A2SLDD from Costco for $149 hoping to set it up with a twin tap tower. Based on some of the kegerator conversions I've seen online for similar Danby models I didn't expect much of a problem. I knew that I was going to have to modify the door.

Following the pictures in this post:

BeerGuy2009's Danby Door Post I set to work with a dremel and a hacksaw to modify the door on my Danby.

When I finished cutting away at the door I found that the door would still not close properly with both kegs inside. I was stumped for a bit until I realized that this model had the shelf supports molded into the sides of the refrigerator while the other models had support brackets that plugged into the back of the unit. The new molded shelf supports made it impossible to fit both corny kegs. I was going to have to remove those shelf supports.

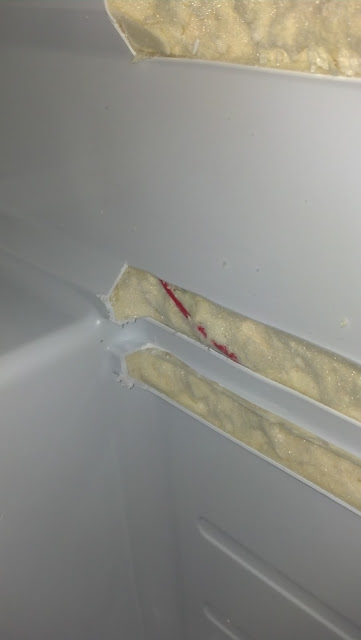

I used a razor/utility knife to cut away the plastic shelf supports. The left side was no problem; cutting the plastic with my knife was fairly easy. I ended up exposing some wiring while working away at the right side though and that made me proceed with great caution. I still don't know how I managed to not cut that red wire. :rockin:

I used some foil tape to cover up all the exposed foam insulation after making all the necessary cuts and now I have the door sealing properly with both kegs inside.

I've got the two kegs running off of a 5 lb tank via a manifold that is mounted inside the fridge.

I plugged her in after getting everything back together and loaded up with the kegs and CO2 and there was no smoke.

The compressor initially ran for 90 minutes and I was worried that I had cut a wire somewhere. But everything in the fridge has now cooled down to 38º F and the compressor only runs as required. The picnic taps will have to do until I get my tower and Perlick's installed.

Don

The compressor initially ran for 90 minutes and I was worried that I had cut a wire somewhere. But everything in the fridge has now cooled down to 38º F and the compressor only runs as required. The picnic taps will have to do until I get my tower and Perlick's installed.

The compressor initially ran for 90 minutes and I was worried that I had cut a wire somewhere. But everything in the fridge has now cooled down to 38º F and the compressor only runs as required. The picnic taps will have to do until I get my tower and Perlick's installed.