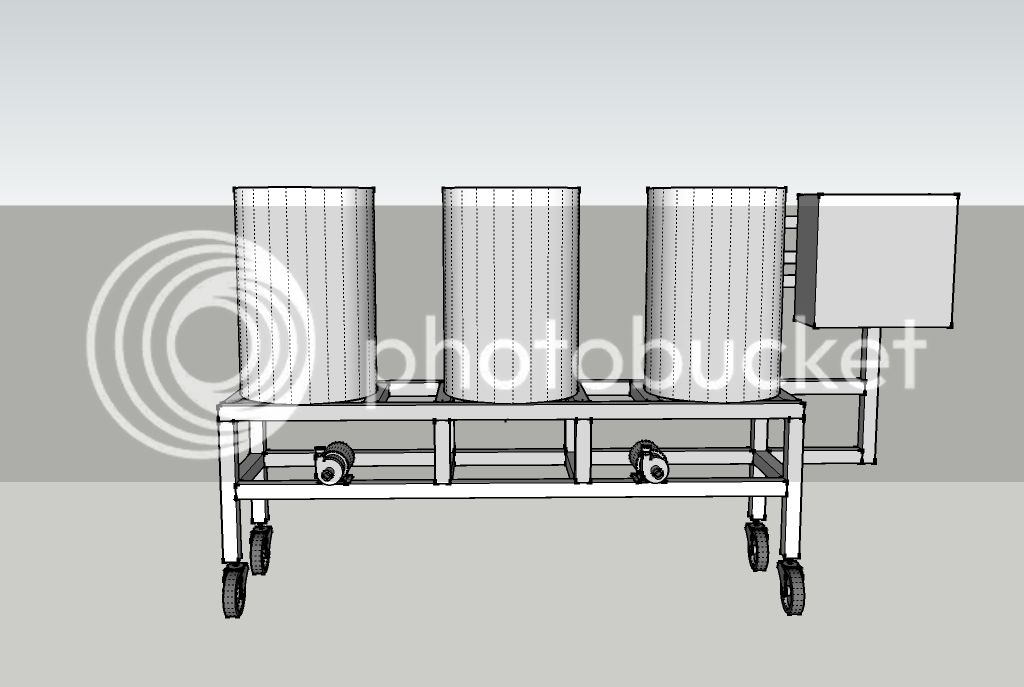

Well Sunday was our funday and we ended up cutting 7 of the 10' 12ga. strut sections and assembled everything.

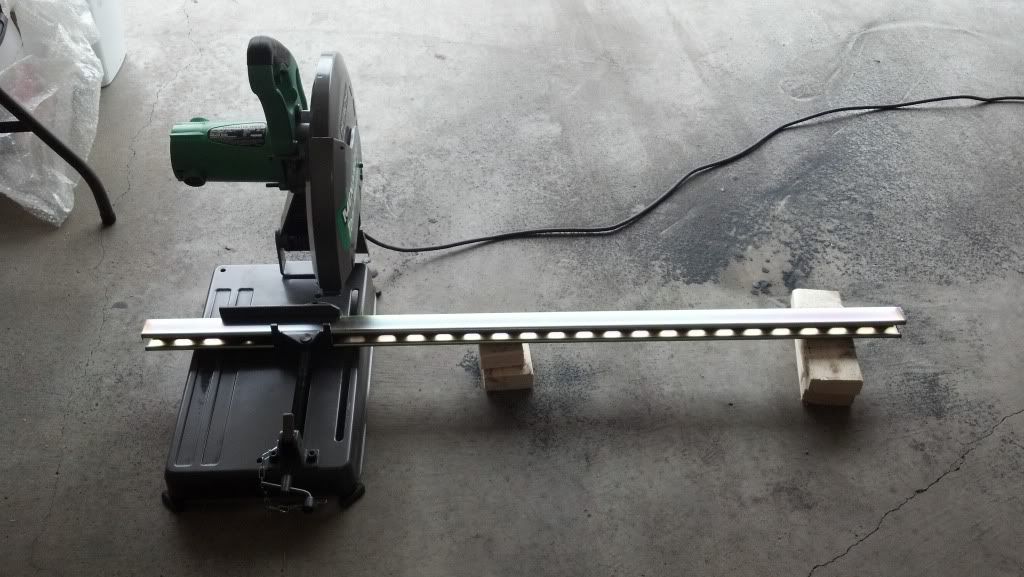

We rented a chop saw for the weekend and if you do, do yourself a favor and go to HD/Lowes and pick up their Dewalt saw blade specifically for stainless steel. There is even a picture of strut on the blade, we bought two of them and they cut through all 32 cuts with out losing even a 1/2" on the blade. Those generic grinding blades suck and you will spend more then you want as you blow through those.

For the stand we are using natural gas that I recently had installed professionally. Something about a denied homeowners claim made me not want to do it myself. Right now we only have one of the burners hooked up and we used a 23 tip jet burner. I know a lot of people find them difficult or a pain, but honestly we are controlling the gas flow with a gate valve and a ball valve as a shut off. It has worked like a charm so far so we ordered another one from Amazon for $24. It is more heat then we need on a keggle system... so I guess we will have to start doing larger batches :rockin:

I have a parts list also included in the pictures, and we had to do a HD trip to pick up a few brackets for extra supports we made after the initial build. But if you go by my plans everything on the parts list will be enough.

For the plans I used Google Sketch Up which is a free program also.

We didn't run in to any "gotchas" or injure ourselves which was great and to cap it off we celebrated by doing a "wet" run of the system and enjoyed a Hopslam which is finally being released.

Enjoy and feel free to ask if you have any questions.

Here is a link to the full album if you want to check it out.

http://imgur.com/a/kRltd/all