If you want to get an answer, you should probably specify the person's name you are asking the question.

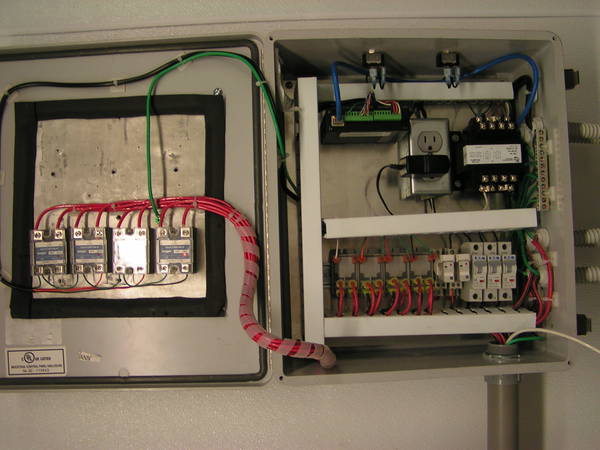

That's what I was going to say... but if it was referring to me, I built it. (Only reason I guess it was me.. was that I was the most recent posting one with a control box)