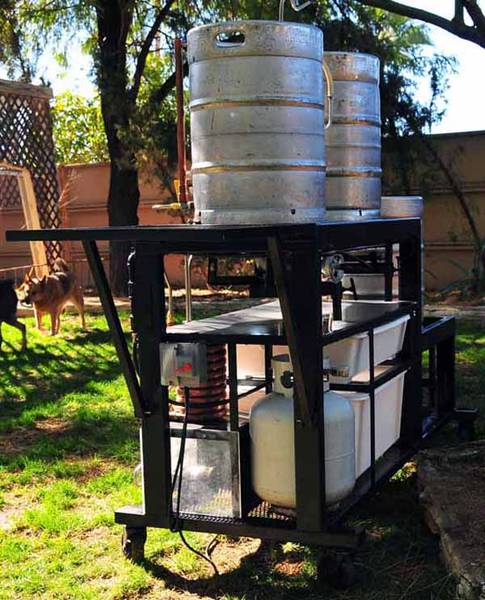

ThirstyNomad

Member

Great minds think alike.

BTW, thirsty, what do you have under your burner? I have two pieces of 2x6, and even though the inside edges are not directly under the burner, they got too hot to touch. No sign of burning, but I'm definitely gonna stand by and watch when the burner is on.

Some Ply - I got a bit nervous after your post so i conducted a heat test of my own. It was really hot, no scorching or burning though - worse i guess is that it could crack. maybe should add a fire extinguisher to the side.