Thunder_Chicken

Well-Known Member

- Recipe Type

- All Grain

- Yeast

- Nottingham

- Yeast Starter

- Krausen beer from another batch

- Batch Size (Gallons)

- 1

- Original Gravity

- 1.050

- Final Gravity

- 1.005

- Boiling Time (Minutes)

- 60

- IBU

- 49.6

- Color

- 5.1

- Primary Fermentation (# of Days & Temp)

- 10 days at 65 °F

- Secondary Fermentation (# of Days & Temp)

- None

- Additional Fermentation

- None

- Tasting Notes

- Drinks like a starchy iced tea, dry mild hop bitterness and tannins, mild and dry.

This was my original (bad) swipe at the recipe (see posts below for results)

1 gallon batch

60 minute boil

FERMENTABLES:

2 lb - Wheat Bran

1 lb - Lyle's Golden Syrup - (late addition) (33.3%)

HOPS:

0.20 oz - Magnum for 60 min, Type: Pellet, Use: Boil (AA 9.2)

On further review, tasting notes from this recipe, and additional experiments by Stonecutter2, it seems that the following is a far better recipe and is far more faithful to the original brew:

George Washington's Small Beer Recipe

1 gallon batch

180 minute boil Washington specifies a 3-hr boil, and Stonecutter2's experiments seem to confirm that an extended boil improves this beer.

FERMENTABLES:

0.5 lb Wheat Bran This amount seems more consistent with the mass of bran in a bushel and produces a 4% ABV brew more fitting to a 'small beer' description.

1 lb Lyle's Golden Syrup (late addition) One 11 fl. oz. bottle of Lyle's Golden Syrup contains 15.4 ounces (by mass) of syrup. Close enough to 16 oz. or 1 lb.

HOPS:

A total of 0.5 oz per gallon of an low alpha English or noble hop variety seems appropriate.

Stonecutter2 did 0.25 oz additions of Liberty at 60 min and 10 min remaining in the boil.

YEAST:

Danstar - Nottingham Ale Yeast

Boil 2.5 gallons of water to boil.

Boil 0.5 lb of wheat bran for 3 hours hours.

Add 0.25 oz. Liberty at 60 minutes and 10 minutes remaining in boil.

Strain wort into second pot at flameout.

Add Lyle's Golden Syrup to hot wort.

Cool to about 90 F, pitch yeast.

Ferment 7-10 days, bottle still.

Stonecutter's experiments suggest extended aging (a few months) greatly improves this brew. Serve chilled.

STATS (from Stonecutter's 3 hr brew, 10/13, post #38 below)

Original Gravity: 1.034

Final Gravity: 1.003

ABV (standard): 4.07%

The History

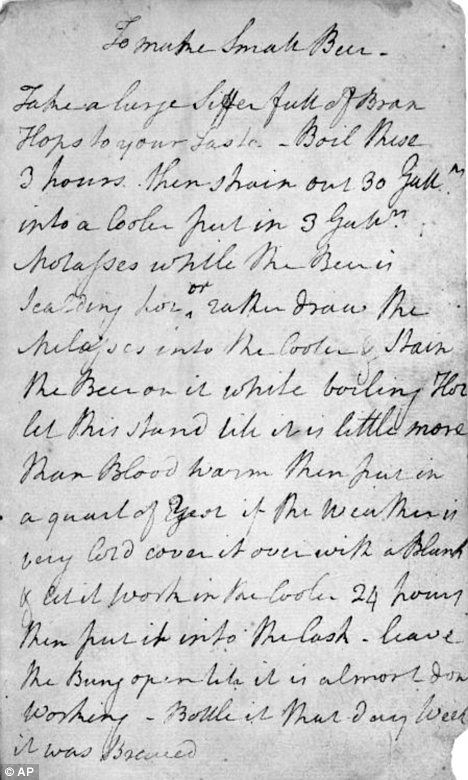

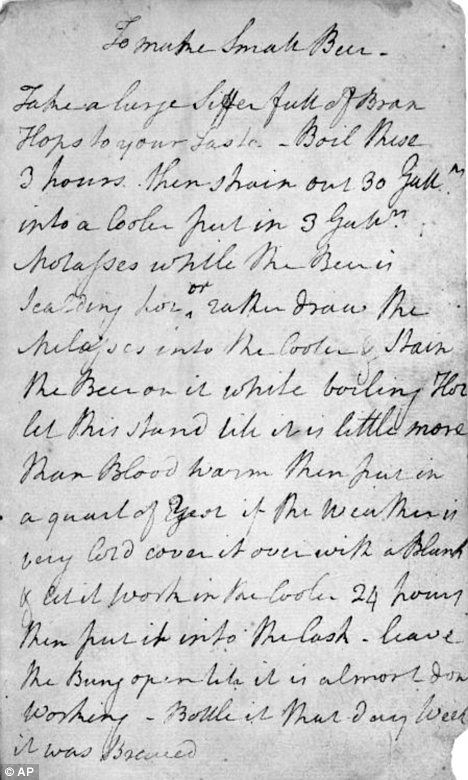

George Washington had a house "Small Beer" recipe that has been bounced around these and other homebrew forums. Some historical interpretation is required to derive a modern day version from George's handwritten recipe:

A couple of notes on terminology:

Sifter

A Sifter is one of these things, used to separate grain, likely wheat.

So a "large Sifter full of Bran" was about a bushel of grain. If the sifter was about 1 bushel in volume, this reference puts bran at about 20 lbs/bushel. That would suggest 0.5 lbs of bran per U.S. gallon (my first attempt at this brew used 2 lbs/gal. based on a questionable earlier assumption). Bran was a common grain used in house beers as malted grains like barley could only be obtained from Britain at high costs. Wheat bran and molasses from the southern colonies and the Caribbean were cheap and plentiful.

BRAN

Using bran apparently was a peculiarity of early American brewing as malted grains had to be imported from England and were therefore pricey, and such malted barley that was available was reserved for distilling (a higher value added use of the limited malted grain). The habit was to make due with locally produced unmalted grains in homebrewed beers. There is a good discussion of this in this BYO article.

http://byo.com/stories/item/1324-revolutionary-brewing

There are also references to similar "bran beers". There is a recipe in a book called Mackenzie's Five Thousand Receipts, written in 1854.

http://openlibrary.org/books/OL17982722M/Mackenzie's_five_thousand_receipts

I'm not sure what the ppg of wheat bran is, but this recipe provides some clues (if it is correct).

15 lbs of sugar in a barrel (assuming a 34 imperial gallon beer barrel) is a fair amount of sugar. I get a gravity of 1.017.

The amount of grain is given in terms of cost - 2 pence per gallon, and the cost of bran being 4 shillings per hundredweight. 12 pence to a shilling...

(100 lb/cwt) × (1 cwt/4 s) × (1 s/12 d) × (2 d / imp. 1 gallon) × ( 1 imp. gallon / 1.20095 U.S. gallon) = 3.5 lbs/U.S. gal

So 17 points/3.5 lbs per gallon ~ 5 ppg. This is in rough agreement with the gravity measurements that I made during the boil, about 7 ppg.

Boil or Mash?

3.5 lbs/gal from the Mackenzie recipe is approximately 1.1 qt/lb, a pretty thick mash. In George's recipe, approximately 20 lbs per 33 imperial gallons of wort produced, so this is a much runnier boil of nearly 8 qts/lb, not accounting for grain absorption and boil-off. In my original recipe I used 2 qt/lb, based on dubious estimates of the amount of bran in a bushel.

Molasses

Molasses did (and still does) come from a process of refining, each boiling producing vastly different flavors and colors. The "molasses" referred to in the recipe was likely first boil or light molasses, which is best described as pale treacle or invert sugar. Lyle's Golden Syrup is probably the closest commercial version to the intended "molasses" in Washington's recipe. The dark and blackstrap molasses familiar to us today, made from later boilings of the cane juice, would make a brew the color of roofing tar and would have a flavor inappropriate for a "small beer". It may be more accurate to use a mix of mostly Lyle's syrup and some dark molasses for some additional flavor.

Hops

Traditional low alpha English hops were probably intended for this brew as they were grown in the Americas. Fuggles or EKG or any hops with clean bittering would be fine as it is only going to provide bittering. "Hops to your taste" is about right.

1 gallon batch

60 minute boil

FERMENTABLES:

2 lb - Wheat Bran

1 lb - Lyle's Golden Syrup - (late addition) (33.3%)

HOPS:

0.20 oz - Magnum for 60 min, Type: Pellet, Use: Boil (AA 9.2)

On further review, tasting notes from this recipe, and additional experiments by Stonecutter2, it seems that the following is a far better recipe and is far more faithful to the original brew:

George Washington's Small Beer Recipe

1 gallon batch

180 minute boil Washington specifies a 3-hr boil, and Stonecutter2's experiments seem to confirm that an extended boil improves this beer.

FERMENTABLES:

0.5 lb Wheat Bran This amount seems more consistent with the mass of bran in a bushel and produces a 4% ABV brew more fitting to a 'small beer' description.

1 lb Lyle's Golden Syrup (late addition) One 11 fl. oz. bottle of Lyle's Golden Syrup contains 15.4 ounces (by mass) of syrup. Close enough to 16 oz. or 1 lb.

HOPS:

A total of 0.5 oz per gallon of an low alpha English or noble hop variety seems appropriate.

Stonecutter2 did 0.25 oz additions of Liberty at 60 min and 10 min remaining in the boil.

YEAST:

Danstar - Nottingham Ale Yeast

Boil 2.5 gallons of water to boil.

Boil 0.5 lb of wheat bran for 3 hours hours.

Add 0.25 oz. Liberty at 60 minutes and 10 minutes remaining in boil.

Strain wort into second pot at flameout.

Add Lyle's Golden Syrup to hot wort.

Cool to about 90 F, pitch yeast.

Ferment 7-10 days, bottle still.

Stonecutter's experiments suggest extended aging (a few months) greatly improves this brew. Serve chilled.

STATS (from Stonecutter's 3 hr brew, 10/13, post #38 below)

Original Gravity: 1.034

Final Gravity: 1.003

ABV (standard): 4.07%

The History

George Washington had a house "Small Beer" recipe that has been bounced around these and other homebrew forums. Some historical interpretation is required to derive a modern day version from George's handwritten recipe:

To Make Small Beer

Take a large Sifter full of Bran [,] Hops to your Taste.

Boil these 3 hours then strain out 30 Gall[ons] into a cooler put in 3 Gall[ons] Molasses while the Beer is Scalding hot or rather draw the Melasses into the cooler & St[r]ain the Beer on it while boiling Hot.

Let this stand till it is little more than Blood warm then put in a quart of Yeat if the Weather is very Cold cover it over with a Blank[et] & let it Work in the Cooler 24 hours then put it into the Cask - leave the bung open till it is almost don[e] Working - Bottle it that day Week it was Brewed. F for 7-10 days. Cool and consume.

A couple of notes on terminology:

Sifter

A Sifter is one of these things, used to separate grain, likely wheat.

So a "large Sifter full of Bran" was about a bushel of grain. If the sifter was about 1 bushel in volume, this reference puts bran at about 20 lbs/bushel. That would suggest 0.5 lbs of bran per U.S. gallon (my first attempt at this brew used 2 lbs/gal. based on a questionable earlier assumption). Bran was a common grain used in house beers as malted grains like barley could only be obtained from Britain at high costs. Wheat bran and molasses from the southern colonies and the Caribbean were cheap and plentiful.

BRAN

Using bran apparently was a peculiarity of early American brewing as malted grains had to be imported from England and were therefore pricey, and such malted barley that was available was reserved for distilling (a higher value added use of the limited malted grain). The habit was to make due with locally produced unmalted grains in homebrewed beers. There is a good discussion of this in this BYO article.

http://byo.com/stories/item/1324-revolutionary-brewing

There are also references to similar "bran beers". There is a recipe in a book called Mackenzie's Five Thousand Receipts, written in 1854.

http://openlibrary.org/books/OL17982722M/Mackenzie's_five_thousand_receipts

Bran beer.

Good fresh table beer may be made with sound wheat bran, at the rate of 2d. per gallon, beer measure, estimating the price of bran at 4s. per cwt, and the saccharine density of the wort еxtracted, at 15 lbs. per barrel; but the use of the instrument called saccharometer, in domestic practice, is not necessary, the process in brewing with wheat bran being sufficiently known to every good housewife, especially to those of labourers in husbandry, as well its that for this purpose nothing of apparatus is needful, but such as ought to be in common use with every cottager in the country. A few pounds per barrel of treacle, or the coarsest Muscovado sugar, would be a cheap improvement as to strength, which indeed might be increased to any degree required.

I'm not sure what the ppg of wheat bran is, but this recipe provides some clues (if it is correct).

15 lbs of sugar in a barrel (assuming a 34 imperial gallon beer barrel) is a fair amount of sugar. I get a gravity of 1.017.

The amount of grain is given in terms of cost - 2 pence per gallon, and the cost of bran being 4 shillings per hundredweight. 12 pence to a shilling...

(100 lb/cwt) × (1 cwt/4 s) × (1 s/12 d) × (2 d / imp. 1 gallon) × ( 1 imp. gallon / 1.20095 U.S. gallon) = 3.5 lbs/U.S. gal

So 17 points/3.5 lbs per gallon ~ 5 ppg. This is in rough agreement with the gravity measurements that I made during the boil, about 7 ppg.

Boil or Mash?

3.5 lbs/gal from the Mackenzie recipe is approximately 1.1 qt/lb, a pretty thick mash. In George's recipe, approximately 20 lbs per 33 imperial gallons of wort produced, so this is a much runnier boil of nearly 8 qts/lb, not accounting for grain absorption and boil-off. In my original recipe I used 2 qt/lb, based on dubious estimates of the amount of bran in a bushel.

Molasses

Molasses did (and still does) come from a process of refining, each boiling producing vastly different flavors and colors. The "molasses" referred to in the recipe was likely first boil or light molasses, which is best described as pale treacle or invert sugar. Lyle's Golden Syrup is probably the closest commercial version to the intended "molasses" in Washington's recipe. The dark and blackstrap molasses familiar to us today, made from later boilings of the cane juice, would make a brew the color of roofing tar and would have a flavor inappropriate for a "small beer". It may be more accurate to use a mix of mostly Lyle's syrup and some dark molasses for some additional flavor.

Hops

Traditional low alpha English hops were probably intended for this brew as they were grown in the Americas. Fuggles or EKG or any hops with clean bittering would be fine as it is only going to provide bittering. "Hops to your taste" is about right.