neb_brewer

Well-Known Member

- Joined

- Apr 22, 2009

- Messages

- 108

- Reaction score

- 0

Hello all,

Like the title says it has been 96 hours since I pitched my yeast and there has been no fermentation yet. Here are the details on everything:

Northern Brewer Kolsch Kit and I decided to go with the dry yeast for my first brew.

"Fermentables

1 lbs. Pilsen Dry Malt Extract (boil for 60 min.)

6 lbs. Pilsen Malt Syrup (boil for 15 min.)

Boil Additions

1 oz. Tradition (60 min)

1 oz. Hallertau Select (30 min)

If you choose dry yeast

Safale US-05. Optimum temperature: 59-75° F."

I did a full boil and didn't run into any problems with the brewing process. I used the IWC that my dad and I built and it worked incredibly well. We cooled the wort down to around 65 degrees in 15-20 minutes. Which we thought was perfect according to our instructions that said 65-75. We pitched (without rehydrating) the yeast and carried it downstairs to our basement closet.

Now, days before I stared my first brew I confirmed that this closet would work with the suggested temperature range suggested with the kit(59-75). After watching the temperature stay at a very consistent 68.5 degrees, I thought it would be perfect for fermenting my kolsch.

I watched the fermentation very closely for the next couple of days and got very worried when I didn't see anything happening but I waited 72 hours like the sticky suggests and still didn't see anything. I decided to email Northern Brewer with an explanation of the situation and this is the reply that I got(at the time I haden't yet checked my gravity):

"The gravity reading will be the only sure way to know if fermentation is taking place; I would bet that it is. If for some reason it isn't, the usual culprit is a temperature that is too low for the yeast. In this case you would want to warm the carboy up so it's within the temp range of the yeast and give it a swirl to re-suspend the yeast. "

I thought that I was well within the range for the yeast according to the instructions......

Tonight I checked my gravity to confirm what has been going on. My OG was 1.053 and tonight when I checked it was again 1.053.

I guess at this point I'm looking for what I can do now. I know that swirling is an option but I just wanted to check with you guys on how vigorous of a swirl that I need to do, ie. what is the goal of the swirl?- Totally "re-stir" the yeast in throughout the wort or just kind of get some stuff off of the bottom.

I also know that re-pitching yeast is an option too, but I live in a small town with no LHBS and will have to order, so if that is my last option what yeast should I order to get this stuff going?

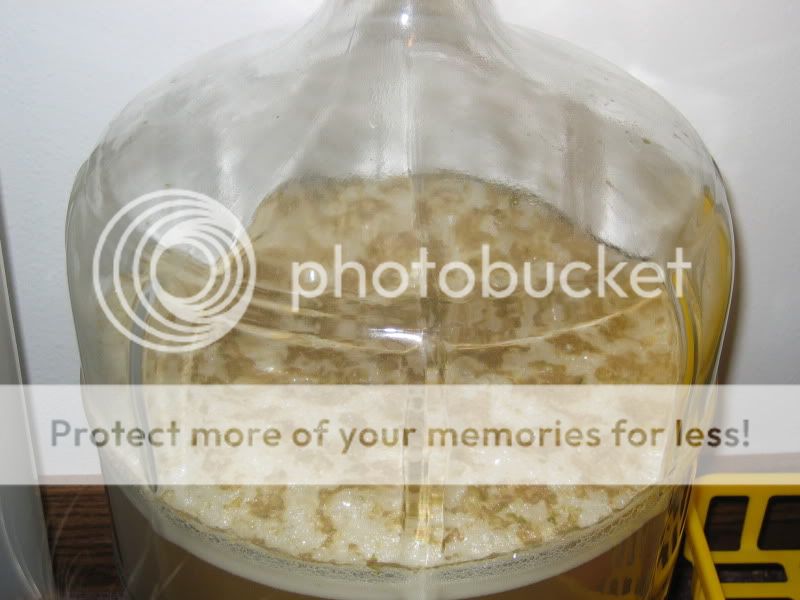

here are some pictures as well:

I tried to give all of the information that I can think of. Let me know if there is anything that you guys need from me to identify what is going on. I appreciate any help!!!!

Like the title says it has been 96 hours since I pitched my yeast and there has been no fermentation yet. Here are the details on everything:

Northern Brewer Kolsch Kit and I decided to go with the dry yeast for my first brew.

"Fermentables

1 lbs. Pilsen Dry Malt Extract (boil for 60 min.)

6 lbs. Pilsen Malt Syrup (boil for 15 min.)

Boil Additions

1 oz. Tradition (60 min)

1 oz. Hallertau Select (30 min)

If you choose dry yeast

Safale US-05. Optimum temperature: 59-75° F."

I did a full boil and didn't run into any problems with the brewing process. I used the IWC that my dad and I built and it worked incredibly well. We cooled the wort down to around 65 degrees in 15-20 minutes. Which we thought was perfect according to our instructions that said 65-75. We pitched (without rehydrating) the yeast and carried it downstairs to our basement closet.

Now, days before I stared my first brew I confirmed that this closet would work with the suggested temperature range suggested with the kit(59-75). After watching the temperature stay at a very consistent 68.5 degrees, I thought it would be perfect for fermenting my kolsch.

I watched the fermentation very closely for the next couple of days and got very worried when I didn't see anything happening but I waited 72 hours like the sticky suggests and still didn't see anything. I decided to email Northern Brewer with an explanation of the situation and this is the reply that I got(at the time I haden't yet checked my gravity):

"The gravity reading will be the only sure way to know if fermentation is taking place; I would bet that it is. If for some reason it isn't, the usual culprit is a temperature that is too low for the yeast. In this case you would want to warm the carboy up so it's within the temp range of the yeast and give it a swirl to re-suspend the yeast. "

I thought that I was well within the range for the yeast according to the instructions......

Tonight I checked my gravity to confirm what has been going on. My OG was 1.053 and tonight when I checked it was again 1.053.

I guess at this point I'm looking for what I can do now. I know that swirling is an option but I just wanted to check with you guys on how vigorous of a swirl that I need to do, ie. what is the goal of the swirl?- Totally "re-stir" the yeast in throughout the wort or just kind of get some stuff off of the bottom.

I also know that re-pitching yeast is an option too, but I live in a small town with no LHBS and will have to order, so if that is my last option what yeast should I order to get this stuff going?

here are some pictures as well:

I tried to give all of the information that I can think of. Let me know if there is anything that you guys need from me to identify what is going on. I appreciate any help!!!!