nostalgia

Well-Known Member

Just got my Brewhemoth today! I'm not going to caption all the pictures, but a few observations:

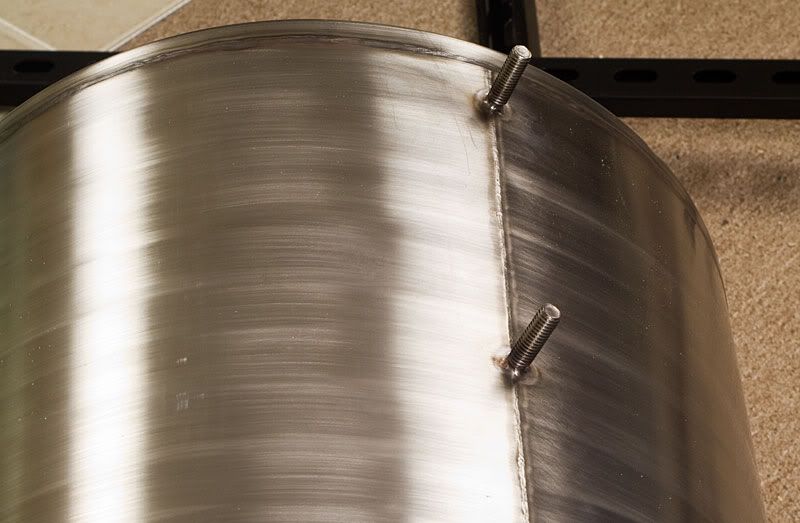

- The steel is nice and heavy.

- The finish on the stainless is a *lot* nicer than I expected. It's very nice to look at.

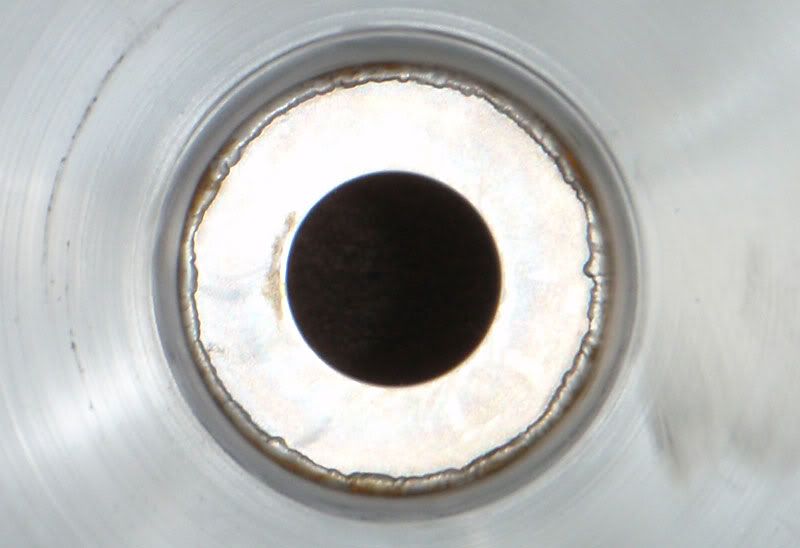

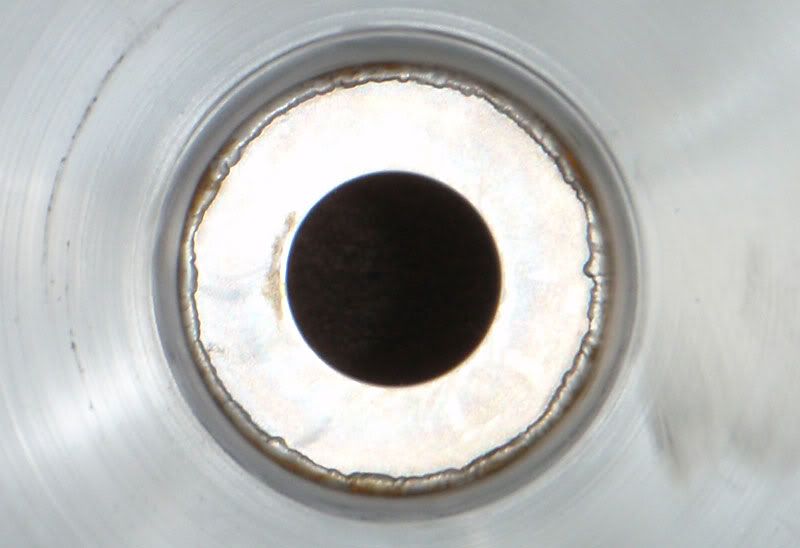

- The welds look nice, but have a bit of surface rust on the inside. A little Bar Keeper's Friend should fix that right up.

- The legs end up tilting in very slightly, making it a bit tippy. I'll be bolting it to a stand, so not a big deal for me.

- The nuts on the feet are welded on only one side. A little chintzy for such a nice product.

Let me know if there are any specific pictures you'd like. I tried to get shots of all the important bits. All of the hardware is from Darren over at Brewer's Hardware. Can't recommend him enough.

-Joe

- The steel is nice and heavy.

- The finish on the stainless is a *lot* nicer than I expected. It's very nice to look at.

- The welds look nice, but have a bit of surface rust on the inside. A little Bar Keeper's Friend should fix that right up.

- The legs end up tilting in very slightly, making it a bit tippy. I'll be bolting it to a stand, so not a big deal for me.

- The nuts on the feet are welded on only one side. A little chintzy for such a nice product.

Let me know if there are any specific pictures you'd like. I tried to get shots of all the important bits. All of the hardware is from Darren over at Brewer's Hardware. Can't recommend him enough.

-Joe