I am in Canada so it isn't really warm enough to use that strategy I don't think... It has snowed about 8 inches in the last 24 hours. What would be involved in hard-wiring the compressor? I figure that swapping the stock controller out for the aquarium controller wouldn't be too hard as long as the wiring is right. I'm not sure how to go about hard-wiring the compressor to stay on.

If you keep your kegerator in an unheated garage, putting the factory sensor on the outside would not work to force the thermostat to keep the compressor active. You said earlier that you don't think you need the heating option. I would think you would, unless you plan to keep this inside your house. In that case putting the factory sensor outside the fridge would keep the compressor active, and would allow you to use the controller sensor to monitor the interior temp.

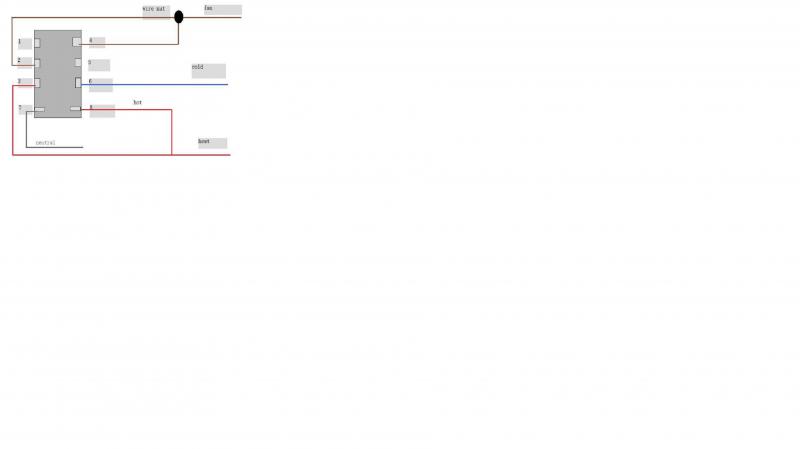

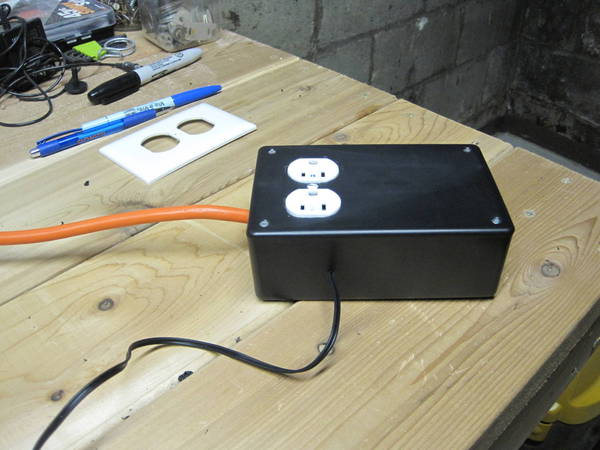

The difficulty of hardwiring the compressor to be always active, or retrofitting the existing thermostat, will depend on the access to the pertinent wires, and your technical understanding. I was trying to offer simpler alternatives. If you are hell bent on retrofitting, there was a previous discussion in this thread that went over it. As long as you have a multi-meter, it should be straight forward to wire and test it.