killsurfcity

Well-Known Member

- Joined

- Feb 11, 2009

- Messages

- 170

- Reaction score

- 18

The chill-down is always the worst part of my brew day. No matter what it takes close to an hour for 5 gallons. i have an immersion chiller, but frankly water baths are faster.

I had an idea tho, how i could use my chiller in a different way and possibly get faster results. I thought I'd post here to see what people thought before I went through the trouble tho.

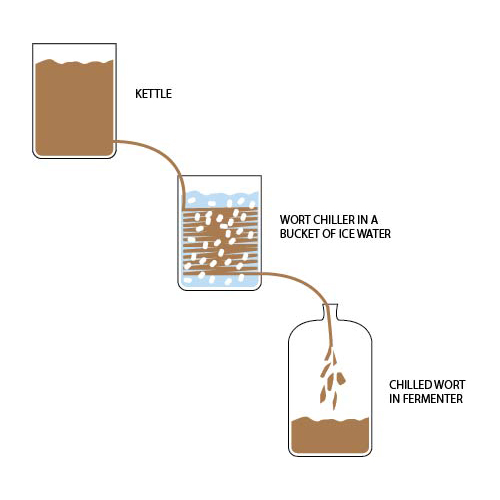

If i have a kettle with a bulkhead on it. I think I could do a gravity transfer to a carboy and chill the wort on the way by running it through my immersion chiller submerged in a cooler full of ice water. The wort would go from the kettle, through high temp tubing, in to the top of the chiller, spiral down through, and out the nozzle of the cooler, into my carboy.

If this works, the only piece of kit i need that i don't currently have, is some hi temp tubing.

Anyone done this?

I had an idea tho, how i could use my chiller in a different way and possibly get faster results. I thought I'd post here to see what people thought before I went through the trouble tho.

If i have a kettle with a bulkhead on it. I think I could do a gravity transfer to a carboy and chill the wort on the way by running it through my immersion chiller submerged in a cooler full of ice water. The wort would go from the kettle, through high temp tubing, in to the top of the chiller, spiral down through, and out the nozzle of the cooler, into my carboy.

If this works, the only piece of kit i need that i don't currently have, is some hi temp tubing.

Anyone done this?