WaboMa

Active Member

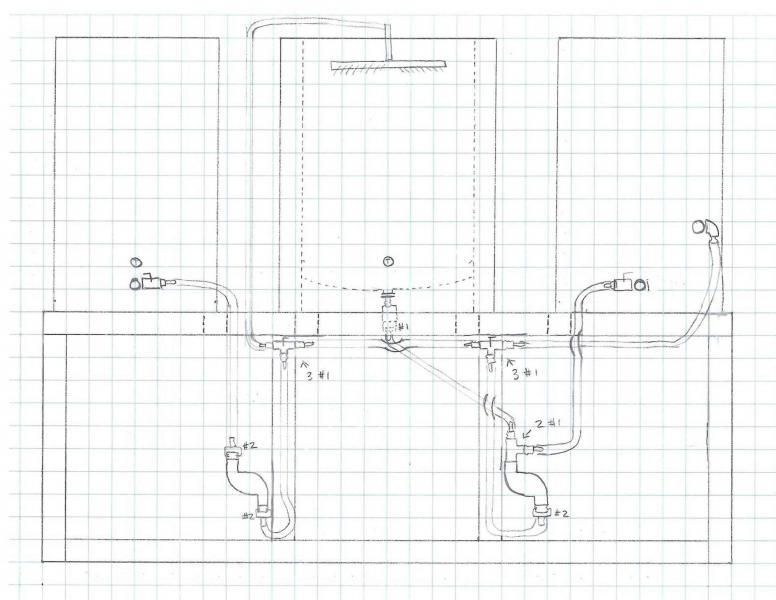

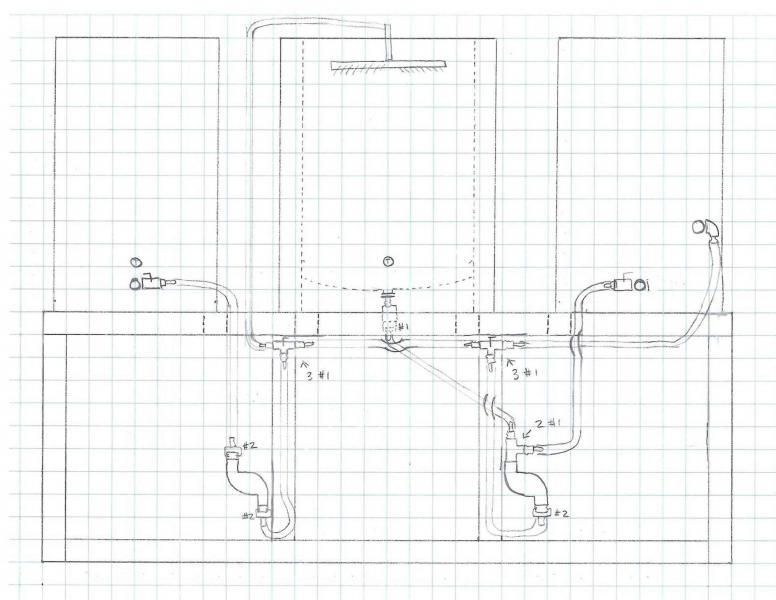

I am starting on a new single tier brew stand and fermentation chamber. My goal is a single tier stand running natural gas, inspired by brutus and all the other awesome builds on this site... but manually ran.

The stand is going to be built out of 2x2 16 gauge cold rolled steel, it will have 2 pumps and will be about the height of a keg. When I started designing the stand I thought it would be bigger Anyways I will start cutting and welding tonight. I am posting the design plans for the stand and plumbing.

I am still working on the natural gas part. The house I live in has a electric water heater in the garage, so there is an open NG gas line just begging for me to use it. I am still a little unsure about the burners but these are the ones I am planning on.

http://www.topfoodservice.com/Merch...CABJ027&Category_Code=KECABJ&Product_Count=23

I do mostly 5G batches, but the plan is to up it to 10G. I will try to post as many pics as I can here are a few including my old three tier brew stand. Also I would appreciate any and all questions, concerns, criticisms...or anything.

Cheers

The stand is going to be built out of 2x2 16 gauge cold rolled steel, it will have 2 pumps and will be about the height of a keg. When I started designing the stand I thought it would be bigger Anyways I will start cutting and welding tonight. I am posting the design plans for the stand and plumbing.

I am still working on the natural gas part. The house I live in has a electric water heater in the garage, so there is an open NG gas line just begging for me to use it. I am still a little unsure about the burners but these are the ones I am planning on.

http://www.topfoodservice.com/Merch...CABJ027&Category_Code=KECABJ&Product_Count=23

I do mostly 5G batches, but the plan is to up it to 10G. I will try to post as many pics as I can here are a few including my old three tier brew stand. Also I would appreciate any and all questions, concerns, criticisms...or anything.

Cheers