For the last 5 years I've been an on-again/off-again all grain stovetop brewer. My system was ugly and tiny, restricted to a 3 gallon batch on the kitchen gas stove. Well, those days are done and I'm currently in the middle of purchasing the components for a single tier system. That's where you guys all (hopefully) come in.

I'm done saving up for a new system and I've settled on a 5 to 10 gallon gas-fired HERMS system sourced through Stout Kettles. With a 15 gallon vessel capacity I should (according to Brewsmith) be able to handle everything from a little 2.5% abv "barely beer" to a big 14% barley wine. My main concern was having a sufficiently large mash tun but once I priced everything out it made sense to upgrade the other two vessels to 15 gallons as well.

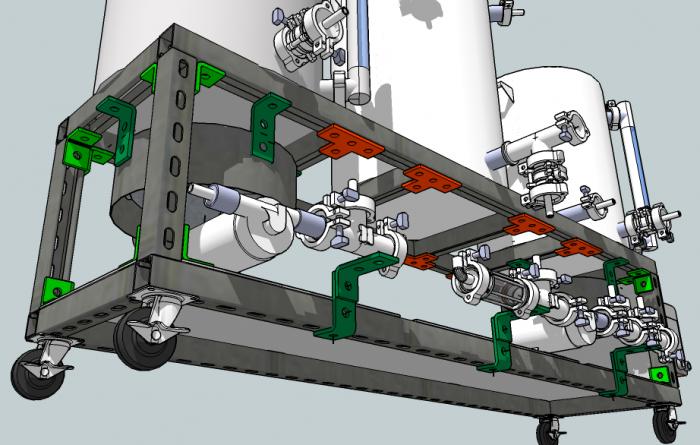

Here's a picture of the entire system minus the liquid and gas plumbing/tubing:

And the stand by itself:

The frame is pretty basic, consisting of five 10ft lengths of 12 gauge superstrut from Home Depot, all the necessary connectors, and two hurricane burners with 4" heat shields from Brewer's Hardware. As much as I'd love a welded unit I neither know any competent welders nor can shell out for a welding unit of of my own given all the other purchases going into this build.

I have the vessels, pumps, and burners in the mail right now but I have a question. Right now I have them designed with the flame bed 2.5" under the kettles. Brewer's Hardware mentions being able to fold over the back end of the shields to improve airflow so I'm planning to do so. This is the first system I've constructed so I'm pretty in the dark here, any advice on burner distance and/or shielding?

The whole setup has a footprint of 1.5 ft x 5 ft and stands 4.5 ft high. Given the nature of strut I should be able to add a control panel and automation on at a later date but so far buying a grain mill, conical, chest freezer, kegging system, stand, and vessels has set me back about $3k so automation will have to wait.

What do you guys think? Any modifications you would recommend?

I'm done saving up for a new system and I've settled on a 5 to 10 gallon gas-fired HERMS system sourced through Stout Kettles. With a 15 gallon vessel capacity I should (according to Brewsmith) be able to handle everything from a little 2.5% abv "barely beer" to a big 14% barley wine. My main concern was having a sufficiently large mash tun but once I priced everything out it made sense to upgrade the other two vessels to 15 gallons as well.

Here's a picture of the entire system minus the liquid and gas plumbing/tubing:

And the stand by itself:

The frame is pretty basic, consisting of five 10ft lengths of 12 gauge superstrut from Home Depot, all the necessary connectors, and two hurricane burners with 4" heat shields from Brewer's Hardware. As much as I'd love a welded unit I neither know any competent welders nor can shell out for a welding unit of of my own given all the other purchases going into this build.

I have the vessels, pumps, and burners in the mail right now but I have a question. Right now I have them designed with the flame bed 2.5" under the kettles. Brewer's Hardware mentions being able to fold over the back end of the shields to improve airflow so I'm planning to do so. This is the first system I've constructed so I'm pretty in the dark here, any advice on burner distance and/or shielding?

The whole setup has a footprint of 1.5 ft x 5 ft and stands 4.5 ft high. Given the nature of strut I should be able to add a control panel and automation on at a later date but so far buying a grain mill, conical, chest freezer, kegging system, stand, and vessels has set me back about $3k so automation will have to wait.

What do you guys think? Any modifications you would recommend?